- Home

- Pet Bottle Blowing Process Step By Step

Step-by-Step Pet Bottle Blowing Process: Manufacturer's Guide for Wholesale and OEM Supply in China

Introducing the incredible Pet Bottle Blowing Process by Zhongshan Sampromold Co., Ltd., your trusted and reliable supplier, manufacturer, and factory based in China. Our step-by-step process ensures the highest quality and precise production of pet bottles.

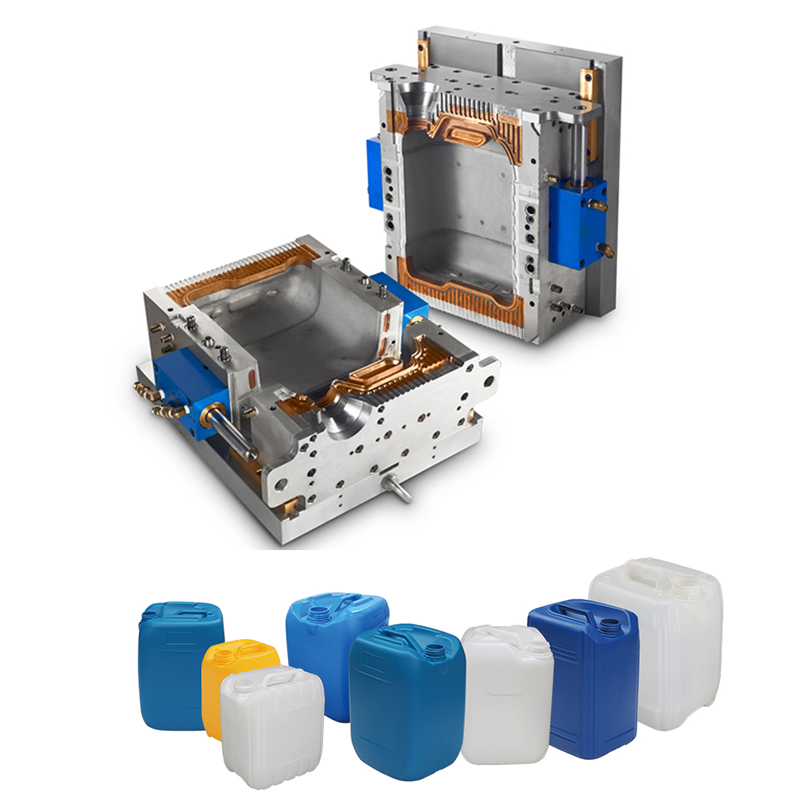

Starting with the initial design, our expert team utilizes cutting-edge technology to create the perfect mold for your specific requirements. Once the mold is ready, our state-of-the-art machines take charge, carefully heating the pet material to the optimal temperature for blowing. This ensures consistent and flawless results.

Next, our skilled technicians meticulously monitor each step of the blowing process, guaranteeing uniformity and durability in every single bottle produced. Whether you need large quantities or small batches, our efficient and flexible manufacturing process allows us to meet your demands with utmost precision and timeliness.

At Zhongshan Sampromold Co., Ltd., we take pride in our commitment to excellence and customer satisfaction. With a focus on quality control, we deliver pet bottles that are not only aesthetically appealing but also meet the highest industry standards.

With our Pet Bottle Blowing Process, we offer you a reliable and efficient solution for all your packaging needs. Trust Zhongshan Sampromold Co., Ltd. to be your trusted partner in providing top-quality pet bottles that will enhance your product's presentation and ensure customer satisfaction.

ZHONGSHAN SAMPROMOLD PRECISE MOULD MAKING CO., LTD

Company News

Related News

5L engine oil bottle blow mold with deflashing

Introducing our premium 5L engine oil bottle blow mold with deflashing. As a factory, we ensure superior quality and efficiency. Order now!

Automobile Maintenance packages XP20210627

Enjoy hassle-free car maintenance with our XP20210627 Automobile Maintenance packages. As a factory, we guarantee top-quality service for your vehicle. Book now!

Fast efficiency wet tissue box injection mold

Looking for fast and efficient wet tissue box injection mold? Look no further! We are a factory specializing in manufacturing high-quality molds. Contact us today!

High quality shampoo blow molding

Get stunning results with our high quality shampoo blow molding products. As a factory, we offer unmatched quality and reliability in English Language.

Hot sell 2L vinegar bottle blow mold

Looking for a high-quality 2L vinegar bottle blow mold? Look no further! We are a factory that specializes in producing top-notch molds for all your packaging needs.

Famous brand personal-care washing bottle blow mold

Looking for high-quality personal-care washing bottle blow mold? Look no further! We are a trusted factory, offering famous brand products. Shop now! #personalcare #blowmold

Water bottle PET blow mould

Looking for high-quality Water bottle PET blow mould? Look no further! We are a leading factory, specializing in manufacturing top-notch moulds.

Stackable bucket blow molding machine mould

Looking for a reliable factory for stackable bucket blow molding machine mould? Look no further! We offer quality products at competitive prices. Visit us today.

Blow moulding barrel 20L/25L/30L

Looking for high-quality blow moulding barrels? Choose from our range of 20L, 25L, and 30L options. As a factory, we offer unrivaled quality and competitive prices. Shop now!

Newtol bottle packages bottle blow mold

Newtol Bottle Packages: Leading factory specializing in bottle blow molding. High-quality product solutions that cater to your packaging needs.

4L/5L exchange stackable drums blow mould

Discover our premium quality stackable drums blow mould - ideal for 4L/5L exchange. As a factory, we offer durable and customizable solutions. Order now!

Medicine packages blow molding

Buy high-quality medicine packages blow molding products from our factory. We specialize in manufacturing top-notch blow molding solutions.

Blow molding machine for pet plastic bottles 24mm bottle molds

Shop our high-quality blow molding machine for PET plastic bottles with 24mm bottle molds. As a professional factory, we offer reliable and efficient manufacturing solutions. Order now!

Household-care washing packages XP21081247

Shop our Household-care washing packages XP21081247 at factory prices. We are a reliable manufacturer, providing top-quality products for all your cleaning needs.

Household-care washing packages XP21081244

Get the best cleaning results with Household-care washing packages XP21081244! As a factory, we provide high-quality and effective solutions for all your cleaning needs. Shop now!

- Step-by-Step Pet Bottle Blowing Process: A Comprehensive Guide for Manufacturers

- Reviews

- Related Videos

Introducing our revolutionary product, the Pet Bottle Blowing Machine. Designed to streamline the bottle manufacturing process, our state-of-the-art machine offers an efficient and effective way to produce high-quality PET bottles. Our Pet Bottle Blowing Machine simplifies the entire bottle production process, step by step. From initial mold preparation to final bottle packaging, our machine delivers exceptional results. The first step entails preheating the PET resin to a specific temperature, optimizing its plasticity for the blowing process. Once the resin is ready, it is carefully loaded into the machine's mold, ensuring accurate placement. Next, the machine swiftly moves into the heating phase, gradually heating the mold and resin to achieve the desired bottle shape. With precise temperature control, our machine guarantees consistent results, eliminating any variations in bottle thickness or wall density. Once the heating phase is complete, the machine transitions to the blowing stage. Utilizing cutting-edge technology, our machine ensures uniform expansion of the plastic, resulting in perfectly shaped bottles every time. This process is highly efficient, with a rapid production rate, minimizing any downtime and maximizing productivity. After the bottles are formed, they are carefully ejected from the mold and proceed to the cooling chamber. Here, our machine swiftly cools the bottles to ensure their structural integrity and to prevent any deformations. Lastly, our Pet Bottle Blowing Machine offers a seamless packaging system, effectively collecting, sorting, and packaging the produced bottles. This automated feature eliminates the need for manual intervention, reducing labor costs and increasing overall efficiency. In conclusion, our Pet Bottle Blowing Machine revolutionizes the bottle manufacturing process, delivering high-quality bottles with speed and precision. Join us in embracing innovation and efficiency in your bottle production with our cutting-edge machine.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours