- Home

- Pet Blow Moulding Process

Pet Blow Moulding Process: Leading Manufacturer and Supplier in China

Introducing the revolutionary Pet Blow Moulding Process, designed to transform your production line and take your packaging capabilities to new heights. Zhongshan Sampromold Co., Ltd., a leading supplier, manufacturer, and factory based in China, presents this cutting-edge technology that will revolutionize the way you manufacture plastic bottles and containers.

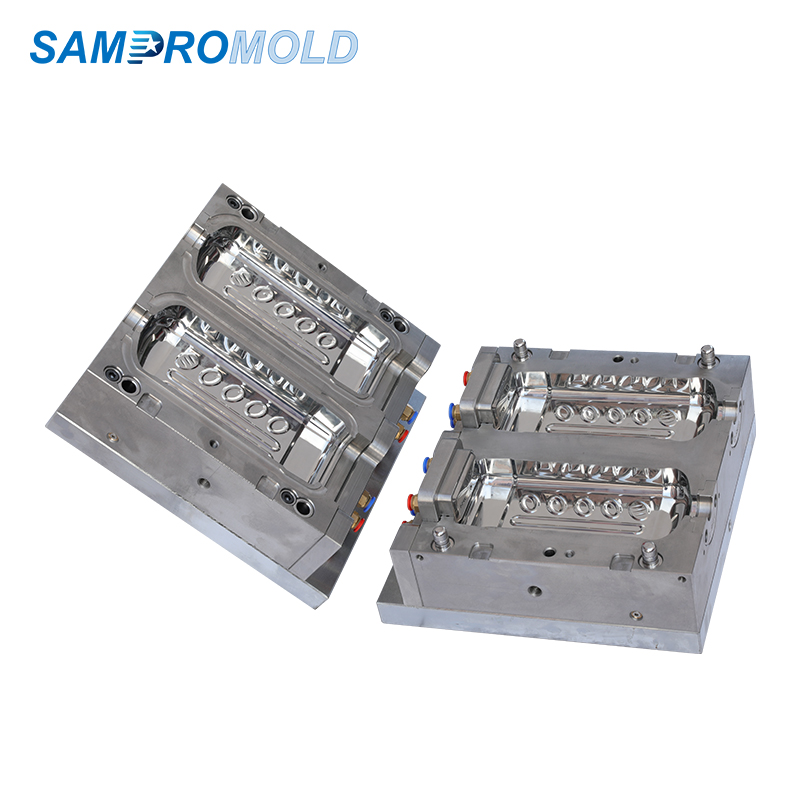

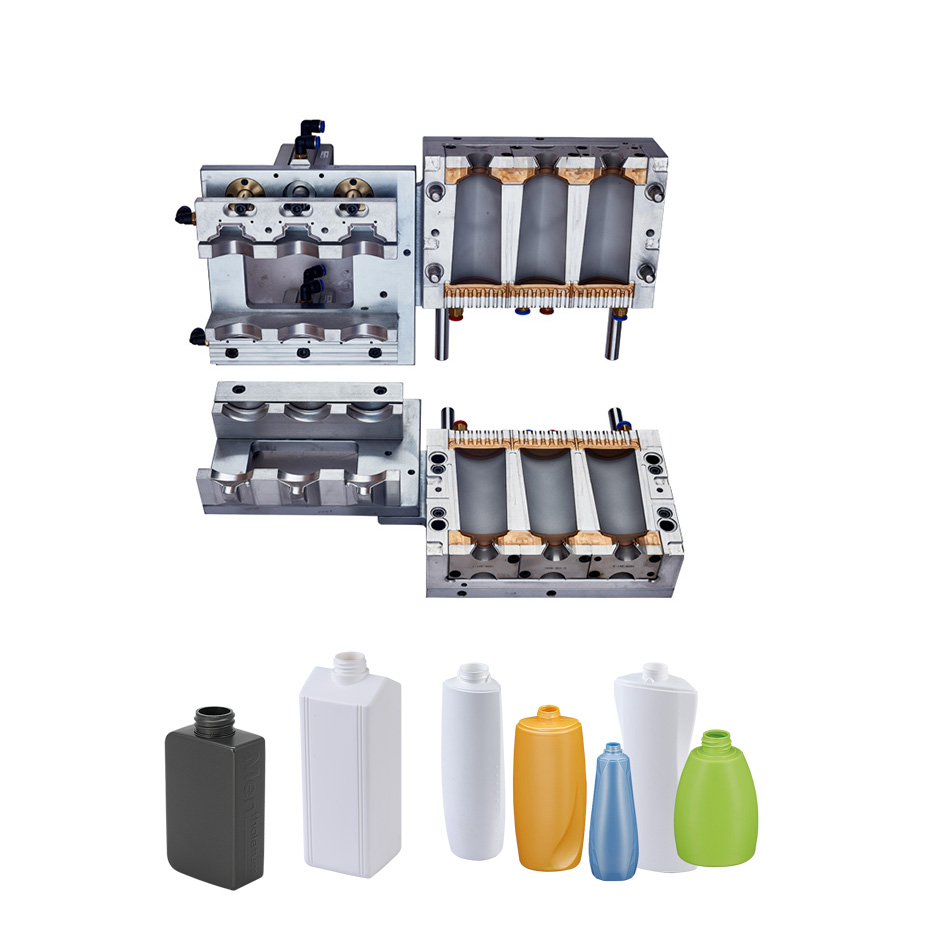

Our Pet Blow Moulding Process is a state-of-the-art solution that provides exceptional precision, efficiency, and durability. By utilizing advanced techniques and high-quality materials, we ensure that every product meets the highest standards of quality and performance. This innovative process allows for the production of consistent and flawless bottles with customized shapes, sizes, and volumes.

With our years of industry expertise and commitment to excellence, Zhongshan Sampromold Co., Ltd. has become a trusted partner for countless businesses around the globe. Our Pet Blow Moulding Process offers unmatched advantages, including reduced production time, minimized material waste, and enhanced productivity. Whether you are in the food and beverage, pharmaceutical, or cosmetic industry, this breakthrough technology will empower your business and elevate your brand. Take your packaging to the next level with Zhongshan Sampromold Co., Ltd.'s Pet Blow Moulding Process and let us help you achieve unparalleled success in the market.

ZHONGSHAN SAMPROMOLD PRECISE MOULD MAKING CO., LTD

Company News

Related News

Household-care washing packages XP21081244

Get the best cleaning results with Household-care washing packages XP21081244! As a factory, we provide high-quality and effective solutions for all your cleaning needs. Shop now!

100ml milk bottle hdpe blow molding machine mould

Introducing our factory's high-quality HDPE blow molding machine mold for 100ml milk bottle production. We specialize in manufacturing and deliver worldwide.

4 cavities lid mould hot runner injection mould

Explore our factory's high-quality 4 cavity lid mould with hot runner injection mould products. Trust us for reliable and efficient manufacturing solutions. Contact us today!

Medicine packages blow molding

Buy high-quality medicine packages blow molding products from our factory. We specialize in manufacturing top-notch blow molding solutions.

1L cleanser essence bottle blow mold

Get the best quality 1L cleanser essence bottle blow mold from our factory. We offer durable and reliable molds to meet your production needs.

Blow moulding barrel 20L/25L/30L

Looking for high-quality blow moulding barrels? Choose from our range of 20L, 25L, and 30L options. As a factory, we offer unrivaled quality and competitive prices. Shop now!

Stackable bucket blow molding machine mould

Looking for a reliable factory for stackable bucket blow molding machine mould? Look no further! We offer quality products at competitive prices. Visit us today.

5L engine oil bottle blow mold with deflashing

Introducing our premium 5L engine oil bottle blow mold with deflashing. As a factory, we ensure superior quality and efficiency. Order now!

Lubricant bottle blow molding machine mould

Looking for the best lubricant bottle blow molding machine mould? We are a factory that specializes in manufacturing top-quality moulds for all your bottle manufacturing needs.

Automatic stretch blow molding for shampoo bottle

Introducing our premier factory offering automatic stretch blow molding for shampoo bottles. Trust us for high-quality production! Contact us today for more information. #ShampooBottle #FactoryProduction #BlowMolding

Household-care washing packages

Introducing our Household-care Washing Packages! Made by our factory, these high-quality products are designed to simplify your cleaning routine. Order now for a spotless home!

Chemical barrel blow molding machine single cavity mold

Looking for a high-quality chemical barrel blow molding machine single cavity mold? Look no further! We are a factory that specializes in producing top-notch molds.

Hot sell 2L vinegar bottle blow mold

Looking for a high-quality 2L vinegar bottle blow mold? Look no further! We are a factory that specializes in producing top-notch molds for all your packaging needs.

Famous brand personal-care washing bottle blow mold

Looking for high-quality personal-care washing bottle blow mold? Look no further! We are a trusted factory, offering famous brand products. Shop now! #personalcare #blowmold

Fast efficiency wet tissue box injection mold

Looking for fast and efficient wet tissue box injection mold? Look no further! We are a factory specializing in manufacturing high-quality molds. Contact us today!

- Top Pet Blow Moulding Process Manufacturer in China - Your Trusted OEM Supplier

- Reviews

- Related Videos

Introducing the innovative Pet Blow Moulding Process, a cutting-edge technology that revolutionizes the production of plastic containers. This groundbreaking process utilizes advanced techniques, ensuring superior quality and efficiency in the manufacturing of pet bottles and jars. With the Pet Blow Moulding Process, you can trust that your products will be crafted to the highest standards. Our state-of-the-art machinery and equipment enable us to create durable, lightweight, and leakage-resistant bottles that meet the demands of various industries, including food and beverage, pharmaceutical, and personal care. The process begins with a preform, a small tube-like structure made from polyethylene terephthalate (PET) resin. This preform is reheated and stretched to optimal dimensions using our specialized blow moulding machines. The moulding process results in uniform walls, precise necks, and seamless finishes, ensuring a seamless packaging solution for your products. One of the key advantages of the Pet Blow Moulding Process is its ability to produce a wide range of bottle shapes and sizes, from small capacity containers to large-volume bottles. Whether you require a sleek, cylindrical design or a unique custom shape, our process can bring your vision to life. We also offer options for embossing or printing, allowing you to showcase your brand identity on each bottle. In addition to its versatility, this process offers remarkable speed and efficiency. Our machines are capable of high-volume production, ensuring swift turnaround times to meet your supply chain demands. Moreover, the Pet Blow Moulding Process is cost-effective, optimizing material usage and reducing production waste. Join the innovation wave in packaging solutions with our Pet Blow Moulding Process. Experience the advantages of superior quality, diverse designs, and efficient production. Contact us today to discuss your packaging needs and explore the endless possibilities this groundbreaking technology presents.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours