Top-rated Stretch Blow Forming Machine: Key Features and Benefits

By:Admin

The Pet Stretch Blow Forming Machine is a state-of-the-art piece of equipment that is used in the production of plastic containers, bottles, and other similar products. It utilizes the stretch blow molding process, which involves the use of heated polymer to create a hollow shape that is then stretched and blown into the desired form. This results in high-quality, uniform, and durable products that meet the strictest industry standards.

The company behind this groundbreaking machine is known for its commitment to excellence and continuous innovation. With a rich history of providing high-quality machinery and unmatched customer service, they have established themselves as a trusted partner for businesses in the packaging and manufacturing industry. Their dedication to research and development has led to the creation of the Pet Stretch Blow Forming Machine, which has set new benchmarks for efficiency and productivity.

One of the key features of the Pet Stretch Blow Forming Machine is its versatility. It is capable of producing a wide range of container shapes and sizes, making it ideal for businesses with diverse product lines. Whether it is small bottles for personal care products or larger containers for beverages, this machine can cater to the varying needs of different industries. This flexibility has made it a popular choice among manufacturers looking to streamline their production processes and enhance their product offerings.

In addition to its versatility, the Pet Stretch Blow Forming Machine is also known for its speed and efficiency. It is equipped with advanced technology that allows for rapid production cycles, resulting in higher output and reduced manufacturing lead times. This is crucial for businesses looking to meet the growing demand for their products while maintaining high standards of quality and consistency.

Furthermore, the Pet Stretch Blow Forming Machine has been designed with cost-effectiveness in mind. It optimizes energy usage and material consumption, thereby lowering production costs and minimizing waste. This not only benefits the bottom line of businesses but also aligns with sustainable manufacturing practices, which are becoming increasingly important in today's market.

The company's commitment to customer satisfaction is evident in the reliable performance and durability of the Pet Stretch Blow Forming Machine. They offer comprehensive support services, including installation, training, and ongoing maintenance, to ensure that their customers can maximize the potential of this cutting-edge technology. Additionally, they are continuously refining and enhancing the machine based on feedback and evolving industry requirements, reaffirming their dedication to delivering value-driven solutions.

In conclusion, the Pet Stretch Blow Forming Machine has emerged as a game-changer in the packaging and manufacturing industry. Its unmatched capabilities, combined with the company's expertise and commitment to innovation, have positioned it as a leading choice for businesses looking to elevate their production processes. With its versatility, speed, efficiency, and cost-effectiveness, this machine is poised to shape the future of plastic container manufacturing and set new industry standards.

Company News & Blog

Durable and Versatile Blow Molding for Rubber Products - A Cost-Effective Solution for High-Volume Production

Blow Molding for Rubber: A Technology Advancement in the Manufacturing IndustryOver the years, the manufacturing industry has undergone tremendous transformations as new technologies and innovations emerge. The rubber industry, for instance, has seen a significant shift in its production process with the introduction of blow molding. In this article, we will explore why blow molding for rubber has become a game-changer in the manufacturing industry.Firstly, it is important to understand what blow molding is. Blow molding is a manufacturing process that involves the shaping of a molten tube of rubber into a hollow object. This process is done by blowing air into the center of a molten tube of rubber, thus creating a mold.Blow molding for rubber has several advantages over other production processes. One of the major benefits is that it is a cost-effective process. Blow molding reduces the number of steps involved in the production of rubber products, thus saving on time and material costs. This means that products can be produced in large quantities at a lower cost.In addition, blow molding allows for the production of complex shapes and designs that are difficult to achieve with other manufacturing processes. Blow molding also produces products with high precision and accuracy, which is essential in the production of components that require exact sizes and shapes.One of the leading companies in the blow molding manufacturing industry is the {brand name}. {Brand name} is a globally recognized company that specializes in blow molding technology. The company has been in the industry for more than 40 years and has provided its clients with quality products and services. {Brand name} provides a wide range of blow molding services including custom product design, prototyping, and mass production.{Brand name} uses state-of-the-art technology and machinery to provide the best blow molding services. The company has a team of experienced engineers and technicians who work tirelessly to ensure that they meet the clients' needs. {Brand name} also ensures that their blow molding services are environmentally friendly and consistent with regulatory standards.Blow molding for rubber has been used in the production of a wide range of products. The products include medical equipment, automotive components, fitness equipment, and toys. Blow molding has also been used to produce products for the food and beverage industry. The process is ideal for producing containers such as bottles, jars, and other packaging materials that require a high level of hygiene.In conclusion, blow molding is a technology advancement that has revolutionized the manufacturing industry, particularly the rubber industry. The process is cost-effective, produces high-precision products, and allows for the production of complex shapes and designs. {Brand name} is a leading company in the blow molding manufacturing industry, providing quality products and services to clients globally. As technology continues to advance, the future of blow molding for rubber looks bright, with more innovations and improvements being developed to enhance the production process further.

Highly Efficient and Durable Blow Molding Clamping Unit for Pet Products

Pet Blow Molding Clamping Unit is the latest innovation from our company, a leading manufacturer of high-quality plastic packaging solutions. This new clamping unit is designed to provide our customers with superior performance and unmatched reliability, further solidifying our position as a trusted industry leader.The new Pet Blow Molding Clamping Unit is the result of years of research and development, leveraging our expertise in plastic molding technology. The clamping unit is designed to meet the growing demand for efficient, high-speed production in the packaging industry. It offers a range of impressive features that set it apart from other clamping units on the market, making it the ideal choice for businesses looking to optimize their production processes.One of the key highlights of the Pet Blow Molding Clamping Unit is its advanced design, which ensures precise and consistent clamping force during the molding process. This results in superior product quality and minimizes the risk of defects or inconsistencies in the final output. The unit also boasts a high level of adaptability, allowing for seamless integration into existing production lines, making it a versatile and practical solution for businesses looking to upgrade their operations.In addition to its superior performance, the Pet Blow Molding Clamping Unit is designed with the user in mind. It features a user-friendly interface and intuitive controls, making it easy to operate and maintain. This not only enhances productivity but also reduces the need for extensive training, ultimately lowering operational costs for our customers.Another significant benefit of the Pet Blow Molding Clamping Unit is its energy efficiency. Our team of engineers has incorporated innovative technology to minimize energy consumption during operation, helping businesses reduce their carbon footprint and lower their overall manufacturing costs.Furthermore, the clamping unit is built to last, constructed from high-quality materials and components that ensure durability and reliability. This minimizes downtime and maintenance requirements, allowing businesses to enjoy continuous production with minimal disruptions.The introduction of the Pet Blow Molding Clamping Unit reaffirms our commitment to providing cutting-edge solutions that empower our customers to achieve their production goals efficiently and cost-effectively. This new offering complements our extensive range of plastic packaging solutions, including blow molding machines, injection molding machines, and ancillary equipment, all of which are designed to meet the diverse needs of our global customer base.As a company, we take pride in our ability to deliver superior products and support services that drive our customers' success. Our team's extensive expertise and dedication to innovation have made us a trusted partner for businesses seeking reliable and high-performance plastic packaging solutions.The launch of the Pet Blow Molding Clamping Unit represents a significant milestone for our company, marking our continued growth and leadership in the industry. We are confident that this new offering will empower our customers to enhance their production capabilities and achieve sustainable growth in the competitive packaging market.Moving forward, we remain committed to advancing the boundaries of plastic molding technology, continuously striving to develop innovative solutions that address the evolving needs of the industry. With a focus on quality, performance, and sustainability, we aim to set new standards for excellence in plastic packaging, further strengthening our position as a preferred partner for businesses worldwide.In conclusion, the Pet Blow Molding Clamping Unit stands as a testament to our unwavering commitment to delivering value-driven solutions that empower our customers to succeed in their respective markets. With its advanced features, user-friendly design, and exceptional performance, this new offering is set to redefine the standard for clamping units in the packaging industry, setting a new benchmark for efficiency, reliability, and overall productivity. We are excited to see the positive impact that the Pet Blow Molding Clamping Unit will have on our customers' operations and look forward to continued collaboration and success in the years to come.

Learn About the Latest Innovations in Blow Molding Machines

Title: Leading Pet Blow Molding Machine Innovator Revolutionizes Manufacturing ProcessIntroduction:With the ever-increasing demand for high-quality plastic bottles and containers, organizations across various sectors are continuously seeking advanced technologies to enhance their manufacturing processes. One such industry leader in the field, a leading developer of Pet Blow Molding Machines, has emerged with groundbreaking solutions that are revolutionizing the production of plastic packaging. By incorporating cutting-edge technology and a commitment to precision and efficiency, this company is reshaping the landscape of manufacturing.Company Background:Established in XXXX, the {Company Name} has been at the forefront of designing, manufacturing, and distributing advanced Pet Blow Molding Machines globally. With a dedicated team of experts and a state-of-the-art research and development facility, the company has consistently delivered innovative solutions that meet the evolving needs of the market. Their commitment to excellence has earned them a stellar reputation within the industry, making {Company Name} a name synonymous with high-quality and reliable machinery.Pet Blow Molding Machine:Utilizing the latest technological advancements, the Pet Blow Molding Machine developed by {Company Name} represents a significant leap forward in the manufacturing process. This machine specializes in the production of plastic bottles and containers made from Polyethylene Terephthalate (PET), a versatile polymer known for its durability and recyclability. The Pet Blow Molding Machine enables organizations to achieve high-speed, precision molding, ensuring consistent results and reduced production time.Key Features and Advantages:1. Rapid Molding Capabilities: The Pet Blow Molding Machine boasts an impressive production capacity, capable of manufacturing a large number of bottles and containers in a short period. This enables companies to significantly increase their output, meeting the ever-growing demand for plastic packaging.2. Precision and Consistency: The cutting-edge technology incorporated in the machine ensures precise control over the molding process, resulting in uniform and consistent bottle quality. From the initial preform heating to the final blown bottle, the system guarantees exceptional accuracy at every stage.3. Energy Efficiency: In today's environmentally conscious world, energy efficiency is a crucial factor for manufacturers. {Company Name}'s Pet Blow Molding Machine has been engineered to minimize energy consumption, reducing the carbon footprint without compromising on productivity.4. User-Friendly Interface: Understanding the significance of ease-of-use, the machine features a user-friendly interface that allows operators to efficiently monitor and control various aspects of the manufacturing process. This intuitive system optimizes workflow and minimizes human errors, ensuring maximum productivity.5. Versatility: The Pet Blow Molding Machine supports a wide range of bottle sizes and shapes, making it suitable for diverse industries such as beverages, cosmetics, pharmaceuticals, and more. This versatility allows manufacturers to adapt to market demands swiftly and efficiently.Impact on the Manufacturing Industry:By incorporating {Company Name}'s Pet Blow Molding Machine into their operations, organizations are benefiting from enhanced productivity, improved product quality, and reduced production costs. The revolutionary technology offered by {Company Name} has streamlined manufacturing processes, enabling businesses to meet consumer demand efficiently. Furthermore, the energy-efficient design of the machine aligns with sustainability goals, helping manufacturers reduce their environmental impact.Conclusion:As the demand for plastic packaging continues to grow, companies must adopt advanced technologies to remain competitive. The Pet Blow Molding Machine, developed by {Company Name}, has emerged as a game-changer in the manufacturing industry. With its exceptional speed, precision, and energy efficiency, this innovative machine is revolutionizing the production of plastic bottles and containers. As {Company Name} continues to redefine manufacturing processes, they solidify their position as a leader in the field, and their groundbreaking solutions reshape the future of the industry.

Exploring the Benefits and Uses of Blow Molded Plastic Containers

Blow Molded Plastic Containers: A Sustainable Solution for Packaging NeedsIn today's fast-paced world, the need for efficient and environmentally friendly packaging solutions is more crucial than ever. As consumers become increasingly conscious of their impact on the environment, companies across various industries are turning to sustainable alternatives for their packaging needs. One such solution gaining traction is blow molded plastic containers. With their versatility, durability, and eco-friendly advantages, these containers are revolutionizing the packaging industry.[Company Name], a leading provider of blow molded plastic containers, has been at the forefront of this transformative movement. With their commitment to sustainability, innovative designs, and exceptional quality, the company has established itself as a trusted partner for businesses seeking eco-conscious packaging solutions.Blow molded plastic containers, also known as blow molded bottles or blow molded jars, are manufactured using a process that involves melting plastic resin and inflating it into a mold. This technique enables the creation of a wide range of shapes and sizes, making them suitable for various industries such as food and beverage, pharmaceuticals, personal care, and household products.The benefits of blow molded plastic containers are abundant. Firstly, they are incredibly durable, providing superior protection for the products they house. Unlike traditional packaging materials like glass or paperboard, blow molded plastic containers are resistant to impact and breakage. This durability ensures that the contents remain safe during transportation and reduces the likelihood of wastage due to damage.Moreover, blow molded plastic containers are lightweight, which not only makes them more cost-effective to transport but also reduces their carbon footprint. The lighter weight results in reduced fuel consumption during shipping, making them an ideal choice for companies striving to minimize their environmental impact.Another notable advantage of blow molded plastic containers is their versatility in design. Companies like [Company Name] offer a wide range of customization options, allowing businesses to create unique packaging solutions that showcase their brand identity. Whether it's designing a distinctive shape, incorporating vibrant colors, or adding textural elements, blow molded plastic containers offer endless possibilities for creative branding.Furthermore, blow molded plastic containers are highly recyclable. With the increasing emphasis on sustainability, consumers are actively seeking products that align with their eco-friendly values. By choosing packaging made from recyclable materials, businesses can meet consumer demands while also contributing to the global effort of reducing plastic waste.To demonstrate their dedication to sustainability, [Company Name] ensures that their blow molded plastic containers are manufactured using high-quality HDPE (High-Density Polyethylene) or PET (Polyethylene Terephthalate) resins. These materials can be easily sorted and recycled, reducing the strain on natural resources and minimizing the environmental impact.Additionally, [Company Name] incorporates cutting-edge technology and best practices throughout their manufacturing process. This includes the use of energy-efficient machinery, waste reduction initiatives, and water conservation strategies. By adopting such practices, the company not only minimizes its own ecological footprint but also helps its clients achieve their sustainability goals.One of the notable success stories of the company is its collaboration with a leading food and beverage company, ABC Corporation. By utilizing blow molded plastic containers from [Company Name], ABC Corporation witnessed a significant reduction in packaging waste, which not only saved costs but also enhanced their brand image as an environmentally responsible company.In conclusion, blow molded plastic containers have emerged as a sustainable solution for businesses across various industries. With their durability, lightweight nature, versatile design options, and recyclability, these containers offer a multitude of benefits while minimizing environmental impact. Companies like [Company Name] are leading the way in providing high-quality blow molded plastic containers, helping businesses meet their packaging needs while aligning with the global push towards sustainability. As consumers continue to prioritize eco-friendly choices, it is evident that blow molded plastic containers are here to stay as a preferred packaging solution.

High-Performance 5 Liter Blow Moulding Machine for Efficient Production

5-Liter Extrusion Blow Moulding Machine: A Game-changer for Plastic Packaging IndustryThe plastic packaging industry is undergoing a significant transformation with the introduction of the new 5-Liter Extrusion Blow Moulding Machine by [Company Name]. This cutting-edge technology is set to revolutionize the production of plastic containers, bringing unprecedented efficiency and quality to the manufacturing process.The 5-Liter Extrusion Blow Moulding Machine is designed to meet the growing demand for high-quality plastic containers in various industries such as food and beverage, pharmaceuticals, and personal care. With a focus on precision and speed, this state-of-the-art machine is capable of producing a wide range of plastic containers with capacities up to 5 liters, making it an ideal choice for manufacturers looking to cater to diverse packaging needs.One of the key features of the 5-Liter Extrusion Blow Moulding Machine is its advanced automation capabilities, which enable seamless operation and minimal human intervention. This not only enhances the overall production efficiency but also ensures consistent product quality, meeting the stringent standards of the packaging industry.Moreover, the machine is equipped with innovative mold and die technology, allowing for the production of complex container designs with remarkable precision. This opens up new possibilities for manufacturers to create unique and eye-catching packaging solutions, giving them a competitive edge in the market.In addition to its technical prowess, the 5-Liter Extrusion Blow Moulding Machine is also designed with sustainability in mind. It is capable of utilizing a variety of environmentally friendly materials, such as biodegradable plastics and recycled resins, supporting the industry's commitment to reducing its carbon footprint and promoting a circular economy.[Company Name], the leading manufacturer behind this groundbreaking technology, has a long-standing reputation for delivering cutting-edge solutions to the plastic packaging industry. With a strong focus on innovation and customer satisfaction, the company has continuously pushed the boundaries of what is possible in plastic container manufacturing, and the 5-Liter Extrusion Blow Moulding Machine is a testament to their dedication to excellence.The introduction of this new machine is expected to have a significant impact on the plastic packaging industry, offering manufacturers a cost-effective and efficient solution to meet the growing demand for high-quality containers. Furthermore, with its focus on sustainability, the machine aligns with the industry's increasing emphasis on eco-friendly packaging solutions, making it a valuable asset for companies looking to enhance their environmental credentials.As the plastic packaging industry continues to evolve, the 5-Liter Extrusion Blow Moulding Machine represents a major leap forward in the quest for efficiency, quality, and sustainability. With its advanced capabilities and innovative design, it is poised to become a game-changer for manufacturers looking to stay ahead in a competitive market.In conclusion, the introduction of the 5-Liter Extrusion Blow Moulding Machine is a significant development for the plastic packaging industry, offering a powerful combination of precision, speed, and sustainability. As manufacturers embrace this new technology, they will be able to elevate their production capabilities and offer cutting-edge packaging solutions to their customers, driving the industry towards a more efficient and environmentally friendly future.

Silicone paw molds for small pets: A versatile addition to your crafting supplies

{company name}, a leading supplier of silicone molds and baking supplies, has recently launched a new product that is sure to excite pet owners and baking enthusiasts alike. The Small Pet Paw Silicone Molds are the latest addition to {company name}'s extensive range of high-quality molds, designed to add a touch of cuteness and creativity to homemade treats.These silicone molds are perfect for creating adorable paw-shaped goodies for small pets, such as dogs and cats. Whether it's for a special occasion, like a pet's birthday or adoption anniversary, or just to show some extra love and care, these molds make it easy to bake cute and tasty treats for beloved furry friends. The molds can be used to make a variety of treats, including biscuits, cookies, and even frozen treats for hot summer days.What sets these Small Pet Paw Silicone Molds apart is their durability and versatility. Made from food-grade silicone, they are flexible, non-stick, and easy to clean, making them ideal for both baking and freezing. The molds are also heat resistant and can withstand temperatures ranging from -40 to 230 degrees Celsius, making them safe for use in the oven, microwave, freezer, and dishwasher.In addition to being practical, these molds are also incredibly cute. The intricate paw design is sure to capture the hearts of pet owners, and the mini size of the paws makes them perfect for creating bite-sized treats for small pets. The molds come in a set of {number} and are available in a variety of colors, allowing users to mix and match to their heart's content.{company name} has always been committed to providing innovative and high-quality baking supplies, and the Small Pet Paw Silicone Molds are no exception. With their attention to detail and dedication to customer satisfaction, the company has quickly become a trusted and beloved brand among home bakers and pet owners."We are thrilled to introduce our Small Pet Paw Silicone Molds to the market," said {Name}, the founder of {company name}. "As pet lovers ourselves, we understand the joy of spoiling our furry friends with special treats. With these molds, we hope to empower pet owners to create homemade goodies that are not only delicious but also adorable."The launch of the Small Pet Paw Silicone Molds comes at a time when more and more people are turning to baking as a way to de-stress and express their creativity. With the rise of social media and the desire for personalized experiences, there is a growing demand for unique and visually appealing baking tools. {company name} recognizes this trend and is continuously working to develop new products that meet the needs of modern consumers.The response to the Small Pet Paw Silicone Molds has been overwhelmingly positive, with pet owners and baking enthusiasts alike expressing their excitement and satisfaction with the new product. Many have taken to social media to share their creations, showcasing the versatility and charm of the molds.In addition to the Small Pet Paw Silicone Molds, {company name} offers a wide range of silicone molds for various occasions and purposes, as well as other baking supplies such as decorating tools, baking mats, and cake molds. With a commitment to quality, creativity, and customer satisfaction, {company name} continues to be a go-to source for home bakers and pet owners alike.For those interested in getting their hands on the Small Pet Paw Silicone Molds or any other products from {company name}, they are available for purchase on the company's website and through select retailers. As the company looks towards the future, they are excited to continue bringing joy and innovation to the world of baking and pet care.

Innovative Blow Molded Sand-Filled Kettlebell: A Functional Fitness Essential

Blow Molded Sand-Filled Kettlebell (need remove brand name)Kettlebells have become a popular fitness tool due to their ability to provide a full-body workout and improve strength, stability, and endurance. With the increasing demand for home fitness equipment, a leading company in the fitness industry has introduced a new blow molded sand-filled kettlebell that is set to revolutionize the way people workout at home.The company, based in (location), is known for its high-quality fitness products that are designed to meet the needs of both fitness enthusiasts and professional athletes. With a strong commitment to innovation and excellence, the company has been at the forefront of developing cutting-edge fitness equipment that delivers outstanding results.The new blow molded sand-filled kettlebell is the latest addition to the company's extensive range of fitness products. Designed to provide a challenging and effective workout, this kettlebell is filled with sand using a blow molding process. This innovative technique ensures that the kettlebell has a durable and long-lasting construction, making it ideal for intense workout sessions.One of the key features of this kettlebell is its ergonomic handle, which is designed to provide a comfortable and secure grip during workouts. This allows users to perform a wide range of exercises with confidence, knowing that the kettlebell will not slip or cause any discomfort. Additionally, the kettlebell is available in a range of weights, making it suitable for beginners and experienced fitness enthusiasts alike.The company's commitment to quality is reflected in the design and construction of the blow molded sand-filled kettlebell. Made from high-quality materials, this kettlebell is built to withstand the demands of regular use, ensuring that it remains a reliable fitness tool for years to come. Furthermore, the sand filling provides a balanced weight distribution, allowing for smooth and controlled movements during workouts.In addition to its outstanding performance, the blow molded sand-filled kettlebell is also designed with convenience in mind. Its compact size and versatile nature make it easy to store and use in a variety of spaces, whether at home or in a commercial fitness facility. This means that users can enjoy a challenging workout without the need for bulky or expensive equipment.As the demand for home fitness equipment continues to grow, the introduction of the new blow molded sand-filled kettlebell comes at a perfect time. With its combination of durability, functionality, and convenience, this kettlebell is set to become a popular choice for individuals looking to enhance their fitness routine from the comfort of their own home.The company's dedication to providing innovative fitness solutions is evident in the development of this kettlebell, and they are proud to offer a product that meets the needs of their customers. With a focus on quality and performance, they are committed to supporting individuals in achieving their fitness goals and leading a healthy lifestyle.In conclusion, the introduction of the blow molded sand-filled kettlebell represents a significant milestone for the company, highlighting their ongoing commitment to delivering exceptional fitness products. As the demand for home fitness solutions continues to rise, this innovative kettlebell is well-positioned to meet the needs of users seeking a versatile, durable, and effective workout tool. With its ergonomic design, durable construction, and convenient size, the blow molded sand-filled kettlebell is set to make a positive impact on the fitness industry, providing individuals with the means to achieve their fitness goals on their own terms.

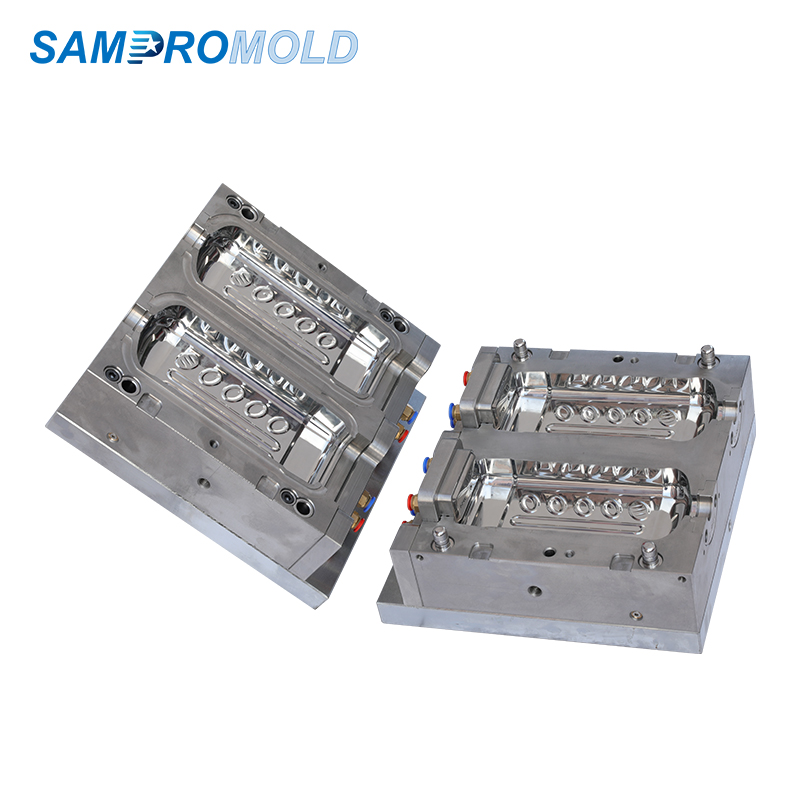

High-Quality Plastic Mold Set for PET Products Offered in Latest News

Title: Industry-leading Pet Plastic Mold Set Revolutionizes Production ProcessesIntroduction (80 words):[Company Name], a renowned pioneer in the manufacturing industry, continues to push the boundaries of innovation with the development of their groundbreaking Pet Plastic Mold Set. This state-of-the-art mold set aims to redefine production processes and streamline operations in the plastics industry. By eliminating wastage, minimizing costs, and improving overall efficiency, [Company Name] solidifies its position as a frontrunner in delivering sustainable and cutting-edge solutions to its global clientele.Content:As the plastics industry continues to rapidly expand, companies are constantly seeking novel ways to optimize production processes, reduce costs, and enhance sustainability practices. Addressing these growing demands, [Company Name] is proud to unveil its highly acclaimed Pet Plastic Mold Set, which promises to revolutionize the manufacturing landscape.1. Unparalleled Precision and Versatility (150 words):The Pet Plastic Mold Set by [Company Name] is designed to deliver unparalleled precision and versatility in the production of various plastic products. With its advanced technology and innovative features, this mold set offers manufacturers the ability to mold PET (Polyethylene Terephthalate) materials into a wide range of shapes and sizes. This paves the way for the creation of high-quality bottles, containers, and packaging materials, among other items, meeting the diverse needs of industries such as food and beverage, pharmaceuticals, and cosmetics.One of the key highlights of the Pet Plastic Mold Set is its exceptional precision, ensuring consistency and accuracy in every mold produced. By eliminating variations, defects, and imperfections commonly associated with traditional molding techniques, manufacturers can experience reduced production downtime and improved product reliability.Additionally, this mold set boasts exceptional versatility, allowing for seamless customization. Manufacturers can easily modify molds to cater to specific product designs and requirements, thereby offering a tailored approach to the manufacturing process.2. Unmatched Efficiency and Sustainability (150 words):[Company Name]'s Pet Plastic Mold Set has been developed with a strong focus on optimizing operational efficiency and global sustainability efforts. By incorporating advanced technologies and manufacturing techniques, the mold set results in significant resource and energy savings during the production process.The streamlined design of this mold set ensures quick mold changes, reducing downtime and increasing overall manufacturing efficiency. Furthermore, its innovative cooling system maximizes cycle times, allowing for faster production rates and increased output.Moreover, the Pet Plastic Mold Set by [Company Name] promotes sustainability by reducing waste and minimizing the environmental footprint. The mold set is designed to minimize material usage, resulting in reduced scrap generation and overall cost savings. By utilizing recycled PET materials, manufacturers can contribute to a circular economy and reduce dependence on virgin plastic production.3. Enhanced Durability and Longevity (150 words):Durability is an essential aspect of any mold set, and [Company Name]'s Pet Plastic Mold Set stands out by providing exceptional quality and longevity. Made from high-grade materials, these molds are engineered to withstand prolonged use, high temperatures, and demanding production conditions.Robust and corrosion-resistant, the Pet Plastic Mold Set guarantees extended lifespan and consistent performance. This ensures that manufacturers experience minimal downtime and increased overall productivity, translating into higher returns on their investment.Moreover, these molds undergo rigorous quality control and testing procedures before reaching the market. This intensive process ensures that each mold meets the highest standards of quality, safety, and reliability, thereby instilling confidence in manufacturers who rely on [Company Name] for their production needs.Conclusion (80 words):[Company Name]'s Pet Plastic Mold Set sets a new benchmark in the plastics industry, offering manufacturers unmatched precision, versatility, efficiency, and sustainability. With its innovative features and superior quality, this mold set is poised to transform production processes, streamline operations, and drive overall industry growth. As [Company Name] continues to pioneer groundbreaking solutions, it reinforces its commitment to shaping a sustainable and prosperous future for the plastics manufacturing sector.

Guide to Using Blow Mould for Manufacturing Process

Blow Mould Industries, a leading manufacturer in the plastic packaging industry, has established itself as a pioneer in the field of blow molding technology. The company has been dedicated to providing high-quality and innovative packaging solutions for a wide range of industries including food and beverage, pharmaceuticals, personal care, and more. With a focus on sustainability and customer satisfaction, Blow Mould has been at the forefront of developing eco-friendly and cost-effective packaging solutions.With over [X] years of experience in the industry, Blow Mould has continually invested in state-of-the-art technology and machinery to meet the evolving needs of its customers. The company's commitment to research and development has led to the creation of cutting-edge blow molding techniques that have revolutionized the packaging industry.Blow Mould's dedication to sustainability can be seen through its eco-friendly packaging solutions that are designed to reduce environmental impact without compromising on performance. By using recycled materials and optimizing packaging designs for efficiency, the company has played a significant role in reducing plastic waste and promoting a circular economy.In addition to its innovative packaging solutions, Blow Mould has also established itself as a reliable and responsive partner for its customers. The company offers customized packaging solutions to meet the specific needs of each client, ensuring that their products are not only protected but also attractively presented on the shelf.Blow Mould's commitment to excellence and customer satisfaction has earned the trust of numerous clients worldwide. The company's dedication to quality and reliability has resulted in long-term partnerships with some of the most prominent brands in the industry.Most recently, Blow Mould has made headlines with the introduction of its latest blow molding technology. The new machinery boasts advanced features that allow for even greater precision and efficiency in the manufacturing process. This breakthrough is set to further enhance the company's capabilities and solidify its position as a leader in the industry.Furthermore, Blow Mould has also been recognized for its contributions to the community through various corporate social responsibility initiatives. The company actively supports local and global causes, and is committed to making a positive impact on society.As Blow Mould continues to push the boundaries of innovation and sustainability in the packaging industry, it remains poised for continued success and growth. With a strong emphasis on quality, reliability, and customer satisfaction, the company is well-positioned to meet the evolving needs of its clients and lead the way in the development of groundbreaking packaging solutions.

Discover the benefits of blow molding for PET bottles

[Company Name] is currently revolutionizing the packaging industry with its innovative blow molding technology for manufacturing PET bottles. The company, [Company Name], has been at the forefront of this technology, setting new standards for quality and sustainability in the production of PET bottles.Blow molding is a manufacturing process used to create hollow plastic parts, such as bottles and containers. The process begins with melting down plastic and forming it into a parison, or a tube-like piece of plastic. The parison is then placed into a mold, where it is inflated using compressed air, taking on the shape of the mold cavity. Finally, the newly formed plastic bottle is ejected from the mold and trimmed to its final shape.[Company Name] has perfected this blow molding technology to produce high-quality PET bottles that meet the highest standards of durability, clarity, and sustainability. Their PET bottles are widely used in the packaging of beverages, personal care products, and household cleaning products.The company has invested heavily in state-of-the-art blow molding equipment, ensuring that their PET bottles are produced with precision and consistency. This dedication to quality has earned [Company Name] a reputation as a trusted supplier of PET bottles to leading brands in various industries.In addition to quality, [Company Name] is committed to sustainability in their manufacturing processes. The company utilizes advanced recycling and reprocessing technologies to minimize waste and reduce their environmental impact. By incorporating recycled materials into their production processes, [Company Name] is contributing to the circular economy and promoting a more sustainable approach to packaging.One of the key advantages of blow molding technology is its ability to produce lightweight yet strong bottles, reducing the amount of raw material required and the overall carbon footprint of the packaging. [Company Name] has embraced this advantage and is continuously innovating to further improve the sustainability of their PET bottles.Furthermore, [Company Name] is dedicated to meeting the specific needs of their customers. They offer a wide range of bottle sizes, shapes, and neck finishes, as well as custom design and branding options. This versatility allows [Company Name] to provide tailored packaging solutions to their clients, helping them to enhance their brand image and customer experience.With their cutting-edge blow molding technology, commitment to sustainability, and customer-focused approach, [Company Name] has positioned itself as a leader in the PET bottle manufacturing industry. As the demand for eco-friendly packaging continues to grow, [Company Name] is well-positioned to meet this demand and drive the industry forward.[Company Name] is also dedicated to ongoing research and development efforts to further improve their blow molding technology and expand their product offerings. By staying ahead of the curve, [Company Name] aims to continue setting new standards for excellence and innovation in the packaging industry.In conclusion, [Company Name] is a pioneering force in the field of blow molding technology for PET bottles. Their unwavering commitment to quality, sustainability, and customer satisfaction has earned them a prominent position in the market. With their advanced manufacturing capabilities and dedication to innovation, [Company Name] is well-equipped to meet the evolving needs of the packaging industry and continue leading the way in the production of PET bottles.