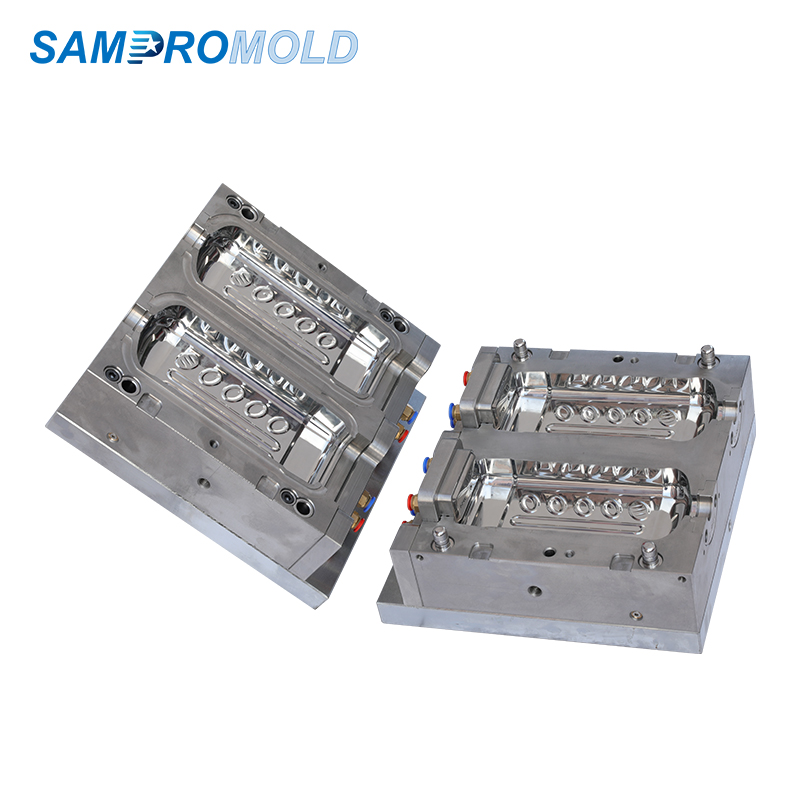

High-Quality Mold for Pet Bottles

By:Admin

Innovative Manufacturing Company Leads the Way in Sustainable Packaging

[Company Name] is revolutionizing the way we think about packaging with their advanced mold for pet bottles. The company's dedication to sustainability and innovation has made them a leader in the manufacturing industry, providing eco-friendly solutions for businesses around the world.

[Company Name] has been at the forefront of sustainable packaging for over a decade, continually pushing the boundaries of what's possible in the industry. Their innovative mold for pet bottles is just one of the many products they offer that are designed to reduce environmental impact while still meeting the high-quality standards businesses expect.

The company's commitment to sustainability is evident in their manufacturing processes as well. They utilize cutting-edge technology and state-of-the-art equipment to minimize waste and energy consumption, ensuring that their products are as eco-friendly as possible. In fact, [Company Name] has received numerous awards and certifications for their environmental initiatives, solidifying their reputation as an industry leader in sustainable manufacturing.

The mold for pet bottles developed by [Company Name] is a game-changer for businesses looking to reduce their carbon footprint. Made from recycled materials and designed for maximum durability, these bottles offer a cost-effective and environmentally friendly solution for packaging needs. Not only do they help businesses meet their sustainability goals, but they also provide a high-quality and attractive packaging option for consumers.

The mold for pet bottles is just one example of the company's dedication to innovation and sustainability. Their team of expert engineers and designers are constantly developing new products and solutions to meet the evolving needs of the industry, always with an eye towards minimizing environmental impact. This commitment to staying ahead of the curve has earned [Company Name] a reputation for being a trusted partner for businesses seeking sustainable packaging solutions.

One of the key factors that sets [Company Name] apart from their competitors is their dedication to customer service and collaboration. They work closely with each of their clients to understand their unique needs and develop customized solutions that align with their sustainability goals. This customer-centric approach has earned them a loyal and satisfied client base, with many businesses choosing to partner with [Company Name] for all of their packaging needs.

As the demand for sustainable packaging continues to grow, [Company Name] is well-positioned to lead the way in the industry. Their mold for pet bottles and other eco-friendly products are a testament to their ongoing commitment to innovation and sustainability, and their dedication to providing the best possible solutions for their clients.

With a proven track record of success and a clear vision for the future, [Company Name] is poised to continue shaping the future of sustainable packaging for years to come. Businesses looking to reduce their environmental impact while still meeting their packaging needs need look no further than [Company Name] for a trusted and reliable partner in the industry.

Company News & Blog

SEO Title: "The Evolution of Plastic Blowing Mold: A Comprehensive Overview

Plastic Blowing Mold - Revolutionizing the Manufacturing IndustryPlastic blowing mold is a process that has been used in the manufacturing industry for years. It involves the use of a variety of machines and tools to create products that are made of plastic. From water bottles to toys and automotive components, the plastic blowing mold process has played an essential role in the creation of many everyday products that we use today.One company that has made significant contributions to the plastic blowing mold industry is a leading manufacturer whose brand name needs to be removed. This company has revolutionized the manufacturing process with its wide range of high-quality products, including blow molding machines, molds, and other auxiliary equipment.The company has been in the plastic blowing mold industry for over two decades and has established a reputation for offering innovative solutions in the market. Boasting a team of engineers and technicians with a vast understanding of the industry, the company has created state-of-the-art designs, which have helped to reduce production costs while optimizing efficiency.One of the secret ingredients that the company has relied on to stay ahead of the competition is its dedication to research and development. They have invested heavily in developing new technologies and designs that help to improve the production process, produce high-quality products with precise specifications, and enhance the longevity of the machines.The company offers a wide range of plastic blowing mold products, including:1. Blow molding machines - These machines are designed to help companies produce a wide variety of hollow plastic products, including water bottles, cosmetic containers, containers for household and industrial chemicals, and automotive components.2. Molds - The company has also created an impressive range of molds that are customized to meet specific customer requirements. The molds are designed to help clients achieve accuracy, speed, and consistency in their production process.3. Auxiliary equipment - The company also provides a broad range of auxiliary equipment, including coolers, dryers, grinders, and conveyors. These devices support the production process and help to optimize the performance of the machines.The company's mission is to provide the best plastic blowing mold solutions while ensuring that the highest quality standards are met. The company's engineers use sophisticated software to design and test molds and machines, ensuring that they offer the best solutions for its clients.Moreover, the company has an in-house quality control department whose primary responsibility is to conduct quality checks and ensure that products meet the specifications before they are shipped to clients. Each product undergoes a series of rigorous inspection procedures, which include dimensional testing, leak testing, and visual examinations, among others. This ensures that the products are of the highest quality standards.Besides guaranteeing top-quality products, the company has also embraced advanced communication systems that ensure that clients' needs are met promptly. Customers can access the company's representatives via phone, email, and social media.In conclusion, the efforts and expertise that the {need remove brand name} has employed in developing the plastic blowing mold industry have revolutionized the manufacturing process. They offer a wide range of high-quality products and auxiliary equipment that have helped many clients in various industries save on cost and time while ensuring that quality standards are met. For businesses looking to make the most out of their production process, the products and services provided by this company are worth investing in.

Extrusion Blow Mold for Bottles: The Latest Advancements

Bottle Extrusion Blow Mold Technology: The Future of Packaging InnovationIn the world of manufacturing, the technology used to create products is constantly evolving. One area that has seen significant advancements in recent years is the production of plastic bottles. The development of Bottle Extrusion Blow Mold technology has revolutionized the way plastic bottles are manufactured, allowing for more efficient production and improved quality.Bottle Extrusion Blow Mold technology is a process that involves the use of a mold to create plastic bottles. This technology has been developed and refined by {Company X}, a leading manufacturer of extrusion blow molding machines. By incorporating state-of-the-art technology and innovative design, {Company X} has established itself as a pioneer in the field of bottle extrusion blow molding.The process begins with the extrusion of a parison, which is a hollow tube of plastic material. This parison is then placed into a mold, where it is inflated to the shape of the mold cavity. The result is a high-quality plastic bottle with consistent wall thickness and precise dimensions.One of the key advantages of Bottle Extrusion Blow Mold technology is its ability to produce bottles with complex shapes and intricate designs. This allows manufacturers to create unique and eye-catching packaging for their products, helping them stand out on the shelves and attract consumer attention.In addition to its design flexibility, Bottle Extrusion Blow Mold technology also offers a number of other benefits. The process is highly efficient, allowing for fast production speeds and minimal material waste. This not only saves manufacturers time and money, but also reduces the environmental impact of plastic bottle production.Furthermore, the bottles produced using this technology are highly durable and have excellent barrier properties. This makes them ideal for packaging a wide range of products, including beverages, personal care products, and household chemicals.With the growing demand for sustainable packaging solutions, Bottle Extrusion Blow Mold technology is well-positioned to meet the needs of today’s environmentally conscious consumers. The process can be used to create bottles from a variety of recyclable plastics, allowing manufacturers to reduce their reliance on virgin materials and minimize their environmental footprint.{Company X} has been at the forefront of promoting sustainability within the industry. Through ongoing research and development efforts, the company has developed processes and materials that align with the global push towards a circular economy. They have also been actively partnering with their customers to optimize their bottle designs for recyclability and maximize the use of post-consumer recycled content.In conclusion, Bottle Extrusion Blow Mold technology represents the future of packaging innovation. With its ability to produce high-quality, environmentally friendly bottles, this technology is poised to play a significant role in the evolution of the packaging industry. As consumer demand for sustainable products continues to grow, manufacturers can rely on Bottle Extrusion Blow Mold technology to meet their needs for efficient, cost-effective, and environmentally responsible packaging solutions. Thanks to {Company X} and their commitment to excellence, the future of bottle manufacturing looks bright.

Top Plastic Injection Molding Services for Your Business Needs

[Precision Plastic Injection Molding Company] is a leading provider of plastic injection molding services, with a focus on delivering high-quality, custom plastic parts to a wide range of industries. With over 20 years of experience in the industry, [Precision Plastic Injection Molding Company] has earned a reputation for excellence and innovation, and is committed to meeting the unique needs of each and every customer.As a full-service plastic injection molding company, [Precision Plastic Injection Molding Company] offers a comprehensive range of services, including product design and development, mold design and construction, and precision molding and assembly. The company's state-of-the-art facility is equipped with the latest in injection molding technology, allowing for the production of complex, high-precision parts with tight tolerances.One of the key differentiators of [Precision Plastic Injection Molding Company] is its dedication to quality and customer satisfaction. The company employs a rigorous quality control process to ensure that every part that leaves its facility meets the highest standards of excellence. This commitment to quality has earned [Precision Plastic Injection Molding Company] numerous certifications and awards, and has established the company as a trusted partner for businesses across a wide range of industries.In addition to its focus on quality, [Precision Plastic Injection Molding Company] is also dedicated to sustainability and environmental responsibility. The company has implemented a number of initiatives to reduce its environmental impact, including the use of recycled materials and energy-efficient manufacturing processes. By prioritizing sustainability, [Precision Plastic Injection Molding Company] is able to help its customers meet their own sustainability goals while also minimizing its own carbon footprint.Recently, [Precision Plastic Injection Molding Company] announced a new partnership with a leading technology company to further enhance its capabilities and expand its offerings. This partnership will enable [Precision Plastic Injection Molding Company] to leverage the latest advancements in injection molding technology, and will allow the company to offer even more innovative solutions to its customers."We are thrilled to announce this new partnership, which will allow us to continue pushing the boundaries of what is possible in plastic injection molding," said [CEO of Precision Plastic Injection Molding Company]. "By combining our expertise with the cutting-edge technology of our partner, we will be able to offer our customers even more advanced and efficient solutions for their plastic part needs."The partnership comes at an exciting time for [Precision Plastic Injection Molding Company], as the company continues to experience rapid growth and expansion. In addition to its new partnership, [Precision Plastic Injection Molding Company] has also recently completed a significant expansion of its facility, adding new injection molding machines and increasing its production capacity to meet the growing demand from its customers."We are incredibly proud of the growth that we have experienced in recent years, and we are excited to continue expanding our capabilities and offerings to better serve our customers," said [CEO of Precision Plastic Injection Molding Company]. "With our new partnership and expanded facility, we are well-positioned to continue providing the high-quality, custom solutions that our customers have come to expect from us."Looking ahead, [Precision Plastic Injection Molding Company] is focused on continuing to innovate and grow, while maintaining its commitment to quality, sustainability, and customer satisfaction. With its new partnership and expanded capabilities, the company is well-positioned to remain a leader in the plastic injection molding industry for years to come.

High-Quality Injection Molding Machine for Pet Preform Production

[Company Name] is pleased to announce the launch of its latest innovation, the Pet Preform Injection Machine. This state-of-the-art machine represents a significant advancement in the company's commitment to providing high-quality and efficient equipment for the pet preform manufacturing industry.The Pet Preform Injection Machine is a fully automated system that is designed to produce high-quality pet preforms with precision and speed. It features advanced technology that ensures consistent molding, high productivity, and energy efficiency. With its user-friendly interface and intuitive controls, the machine can be easily operated by a single operator, reducing the need for extensive training and minimizing the risk of errors.The injection machine is equipped with a robust hydraulic system that ensures stable and reliable operation. It also features a high-performance injection unit that delivers a precise and uniform melt for excellent preform quality. Additionally, the machine is designed to be highly customizable, allowing for easy adjustments to accommodate different preform sizes and specifications.[Company Name] has a long-standing reputation for delivering cutting-edge solutions to the pet preform industry. With a focus on research and development, the company continues to invest in new technologies and innovations to meet the evolving needs of its customers. The Pet Preform Injection Machine is the latest example of [Company Name]'s dedication to providing advanced equipment that enhances production efficiency and product quality."We are very excited to introduce our Pet Preform Injection Machine to the market," said [Company Representative]. "This machine represents a significant leap forward in pet preform manufacturing technology, and we are confident that it will provide our customers with a competitive edge in the industry. With its advanced features and reliable performance, the machine is set to become a game-changer for pet preform production."In addition to its technological advancements, the Pet Preform Injection Machine is also designed with sustainability in mind. It is equipped with energy-saving features that reduce power consumption, contributing to a more eco-friendly manufacturing process. The machine's efficient operation also minimizes material waste, further supporting environmentally responsible production practices.At [Company Name], customer satisfaction is a top priority, and the company's dedication to providing exceptional service extends beyond the sale of its equipment. The Pet Preform Injection Machine is backed by a comprehensive support system, including installation assistance, training programs, and ongoing technical support. This ensures that customers can maximize the machine's performance, minimize downtime, and achieve the highest levels of production efficiency.With the launch of the Pet Preform Injection Machine, [Company Name] continues to solidify its position as a leading provider of innovative solutions for the pet preform manufacturing industry. The company's commitment to excellence, technological expertise, and customer focus makes it a trusted partner for businesses seeking to enhance their production capabilities.For more information about the Pet Preform Injection Machine and other products offered by [Company Name], please visit their website or contact their sales team. With an unwavering dedication to innovation and customer success, [Company Name] remains at the forefront of the pet preform industry, and the introduction of the Pet Preform Injection Machine further reinforces its position as a reliable and forward-thinking equipment supplier.

Revolutionary Screw Cap Mould: The Future of Packaging

Title: Innovative Screw Cap Mould Technology Revolutionizes Bottle PackagingIntroduction:In the fast-paced and constantly evolving world of packaging, the demand for advanced and efficient solutions is ever-increasing. One such technology that is revolutionizing bottle packaging is the Screw Cap Mould, developed by an industry-leading company. This groundbreaking innovation offers significant advantages over traditional packaging methods, ensuring improved sealing, preservation, and overall consumer experience.Company Introduction:With a firm commitment to quality and innovation, the company behind the Screw Cap Mould has been a prominent player in the industry for several decades. They specialize in designing and manufacturing cutting-edge packaging solutions for a wide range of industries, including food and beverages, pharmaceuticals, and cosmetics. Known for their expertise and state-of-the-art facilities, they have established themselves as a trusted partner for businesses seeking efficient and reliable packaging solutions.1. Enhanced Sealing and Security:The Screw Cap Mould boasts an advanced design that ensures enhanced sealing capabilities, mitigating the risk of leakage and contamination. Utilizing precision engineering and high-quality materials, the mould guarantees a tight seal, preventing any unwanted exposure to air, moisture, or other external factors that could compromise the product's quality. Consequently, consumers can trust the integrity of the contents, ensuring a positive user experience.2. Versatility and Customization:One of the key advantages of the Screw Cap Mould technology is its versatility and compatibility with various bottle types and sizes. Irrespective of the container material, be it glass or plastic, the mould can be customized to fit seamlessly, offering a perfect fit and ensuring excellent functionality. Additionally, businesses can personalize the screw caps further, incorporating logos, branding, and other design elements, thus creating a distinct and marketable packaging solution.3. Sustainability and Environmental Benefits:In today's eco-conscious era, sustainably-minded packaging is in high demand. The Screw Cap Mould addresses this need by incorporating environmentally friendly features. It is designed to be reusable, reducing the need for single-use packaging and minimizing waste. Furthermore, the use of recyclable materials ensures that the mould aligns with the principles of circular economy, helping businesses meet their sustainable packaging goals while reducing their carbon footprint.4. Improved Consumer Experience:The Screw Cap Mould not only enhances the packaging's functionality but also contributes to an improved consumer experience. The ease of opening and resealing the screw cap ensures convenience and minimizes spillage risks. The design allows for efficient pouring, preventing drips and leaks during usage. Moreover, the enhanced sealing capabilities maintain the product's freshness and shelf life, providing consumers with a reliable and enjoyable experience every time.5. Cost-Effective Solution:Implementing the Screw Cap Mould technology offers cost-effective benefits for businesses in the long run. With increased sealing and preservation capabilities, the risk of product spoilage and damage is significantly reduced, reducing potential economic losses. The customization options allow for increased brand visibility and recognition, ultimately improving market positioning and revenue generation.Conclusion:As the world embraces innovation and technology, the Screw Cap Mould is emerging as a game-changer in bottle packaging. With its advanced sealing capabilities, versatility, and customization options, the mould provides businesses with a comprehensive solution that enhances their products' integrity and market appeal. Additionally, its sustainable features and improved consumer experience established it as an ideal choice in today's packaging landscape. With the introduction of this pioneering technology, businesses across various industries can look forward to elevating their packaging game to new heights.

Discover the Advantages of Blow Mold Manufacturing for Your Business

In recent years, the demand for blow mold manufactures has been on the rise. Blow Mold Manufacturers (BMM), a leading company in the industry, has been at the forefront of this trend. Known for their commitment to quality, innovation, and customer satisfaction, BMM has been making waves in the market with their wide range of products and services.Founded in 1992, BMM has come a long way since its inception. With a sprawling manufacturing unit spanning over 200,000 sq. ft., BMM has the capacity to produce over 500 molds per year. The company's state-of-the-art technology, coupled with their experienced and skilled workforce, ensures that each product meets the highest standards of quality.BMM's products are widely used in the packaging industry, with applications in the food and beverage, pharmaceutical, and cosmetics sectors. Their range of products includes blow moldings, injection moldings, extrusion blow moldings, and stretch blow moldings, among others. The company also offers custom molding services, which allows them to cater to the unique needs of their clients.One of the key factors that sets BMM apart from its competitors is their focus on innovation. The company is constantly exploring new avenues and adopting cutting-edge technology to enhance their products and services. Their R&D team works closely with clients to identify their needs and develop customized solutions that meet their requirements.BMM's commitment to customer satisfaction is reflected in their after-sales service. The company has a dedicated team of service professionals that provide round-the-clock support to clients. They also offer maintenance and repair services, ensuring that their products continue to perform optimally even after years of use.Over the years, BMM has built a loyal customer base, with clients ranging from small start-ups to large multinationals. The company's products have been used in a wide range of applications, from packaging for household products to medical devices.As the demand for blow mold manufactures continues to rise, BMM is well-positioned to capitalize on this trend. The company's strong focus on quality, innovation, and customer satisfaction sets them apart from their competitors and makes them a preferred choice for clients.Looking to the future, BMM is poised for growth. The company is exploring new markets and expanding their product range to cater to evolving customer needs. They are also investing in research and development to stay ahead of their competitors and continue to lead the industry.In summary, Blow Mold Manufacturers is a leading company in the blow mold industry. With a focus on quality, innovation, and customer satisfaction, the company has built a loyal customer base and is well-positioned for growth in the years to come. Their commitment to excellence and their dedication to meeting the unique needs of their clients make them a preferred choice for businesses in the packaging industry.

Discover the Latest Innovations in Pet Blow Machine Technology

PET Blow Machine enhances efficiency and quality in the production process.In the competitive world of manufacturing, efficiency and quality are paramount. This is where the PET Blow Machine comes into play, revolutionizing the production process for companies in various industries.The PET Blow Machine, developed and produced by a leading manufacturing company, is a state-of-the-art piece of equipment designed to streamline the process of creating PET bottles and containers. With its innovative technology and advanced features, this machine is capable of producing high-quality products at a faster rate, ultimately improving the overall efficiency of the production process.The company behind the PET Blow Machine is a global leader in manufacturing equipment for the packaging industry. With a strong focus on innovation and customer satisfaction, the company has gained a reputation for delivering cutting-edge solutions that meet the evolving needs of its clients.Founded over three decades ago, the company has continuously strived for excellence in its field. With a team of experienced engineers and designers, the company has been able to develop a wide range of products that cater to the diverse needs of its clients. From blow molding machines to preform making machines, the company's product portfolio is extensive and continues to grow as new technologies emerge.The PET Blow Machine is one of the company's flagship products, and it has been well-received by clients around the world. Its ability to produce high-quality PET bottles and containers with precision and efficiency has made it a go-to solution for many manufacturing companies across different industries. With a focus on user-friendly design and advanced automation features, the machine has been lauded for its ease of use and reliability.One of the key features of the PET Blow Machine is its energy-efficient design. By optimizing the use of resources and reducing waste, the machine helps companies minimize their environmental impact while also cutting down on operational costs. This aligns with the company's commitment to sustainability and corporate responsibility, as it continues to develop products that contribute to a greener and more sustainable future.In addition to its efficiency and sustainability benefits, the PET Blow Machine also offers a high level of customization. Clients can choose from a range of options to tailor the machine to their specific production needs, ensuring that they can achieve the results they desire without compromise. This flexibility has been a major selling point for the machine, as it allows companies to adapt to changing market demands and stay ahead of the competition.As demand for PET bottles and containers continues to grow, the PET Blow Machine has become an indispensable tool for many manufacturing companies. Its ability to deliver consistent, high-quality results at a rapid pace has set a new standard for production efficiency in the industry. With the support of the company behind it, the machine is poised to continue making waves in the global manufacturing landscape.Looking to the future, the company remains committed to pushing the boundaries of innovation and delivering solutions that exceed the expectations of its clients. With an eye on emerging technologies and market trends, the company is well-positioned to continue driving positive change in the industry. As a trusted partner for manufacturing companies around the world, the company will undoubtedly remain at the forefront of the industry for years to come.In conclusion, the PET Blow Machine has proven to be a game-changer for manufacturing companies seeking to enhance their production processes. With its focus on efficiency, quality, and sustainability, this state-of-the-art machine is a testament to the company's dedication to innovation and customer satisfaction. As it continues to gain recognition in the global market, the PET Blow Machine is shaping the future of manufacturing and paving the way for a more efficient and sustainable industry.

Common Blow Molding Machine Spare Parts Available in the Market

Title: Leading Blow Molding Machine Spare Parts Provider Announces New Innovations in the IndustryIntroduction:With an extensive history in the production of high-quality blow molding machine spare parts, [Company Name] is a renowned and globally recognized leader in the industry. Today, they have unveiled their latest advancements in blow molding technology, setting a new benchmark for efficiency, precision, and durability. By continuously pushing the boundaries of innovation, [Company Name] remains committed to meeting the evolving needs of their clients worldwide.Body:1. Company Background (100 words)Founded in [Year], [Company Name] has established itself as a trusted name in the blow molding industry. Their commitment to delivering exceptional quality, customer service, and cutting-edge solutions has earned them a strong reputation. Boasting a state-of-the-art manufacturing facility and a team of highly skilled professionals, the company has successfully catered to numerous clients spanning various industries globally.2. New Blow Molding Machine Spare Parts (200 words)In response to the growing demand for superior blow molding machine spare parts, [Company Name] has introduced a range of groundbreaking innovations. Their latest offerings harness advanced technologies to enhance efficiency, reliability, and productivity in blow molding processes.One notable addition is the precision-engineered molds designed to produce intricate shapes and sizes with unparalleled precision. These molds minimize material waste while ensuring optimal strength and uniformity in the final product. Furthermore, the improved cooling systems incorporated into the molds accelerate the production cycle, resulting in increased output and minimized downtime.Moreover, [Company Name] has developed state-of-the-art hydraulic systems that guarantee smooth and consistent equipment operation. These advanced systems optimize energy usage, reducing costs and environmental impact. Their innovative control panels offer user-friendly interfaces, allowing operators to monitor and adjust machine settings effortlessly.3. Commitment to Sustainability (150 words)Recognizing the global shift towards sustainable manufacturing, [Company Name] has steadfastly aligned its operations with eco-friendly practices. Their blow molding machine spare parts focus on reducing energy consumption, enhancing recyclability, and minimizing environmental footprint.By utilizing cutting-edge materials, [Company Name] has significantly lightened the weight of their spare parts while maintaining durability. This reduction in weight not only contributes to energy efficiency but also facilitates easier handling, installation, and maintenance.Another sustainable feature integrated into their spare parts is the incorporation of recyclable materials. This extends the lifecycle of the parts while reducing the industry's reliance on non-renewable resources.4. Global Outreach and Customer Support (150 words)[Company Name]'s commitment to excellence extends beyond the quality of their blow molding machine spare parts. They boast a global distribution network that ensures rapid delivery of spare parts to clients worldwide. This network is supported by a dedicated customer service team proficient in different languages, ensuring efficient communication and resolving customer queries promptly.To enhance customer experience, [Company Name] offers comprehensive after-sales support, including technical assistance, spare part consultation, and maintenance services. Their team of highly trained professionals is readily available to address any customer concerns, ensuring seamless operations throughout the product lifespan.Conclusion (100 words)[Company Name] continues to innovate and set new industry standards with their range of blow molding machine spare parts. Through their dedication to sustainability, advanced technology integration, and robust customer support, they have firmly established themselves as a trusted partner to clients worldwide. Their unwavering commitment to excellence reinforces their standing as an industry leader, poised to drive further advancements in the blow molding industry.

Innovative Blow Molding Machine Technology Revolutionizes Manufacturing Processes

Ziqiang Blow Molding Machine Company, a leading manufacturer of blow molding machines, has recently unveiled its latest innovation in the field of blow molding technology. The company has been at the forefront of blow molding machine production for over 20 years, and its new machine is set to revolutionize the industry.The new blow molding machine features state-of-the-art technology that offers superior performance and efficiency. With a focus on precision and reliability, the machine is designed to meet the growing demand for high-quality blow molded products in various industries such as packaging, automotive, consumer goods, and more.One of the key highlights of the new machine is its advanced control system, which allows for precise and consistent production of blow molded products. This ensures that each product meets the highest standards of quality and consistency, which is essential for manufacturers looking to maintain a competitive edge in the market.In addition to its cutting-edge technology, the new blow molding machine also boasts a user-friendly interface, making it easier for operators to monitor and control the production process. This intuitive interface is designed to minimize downtime and maximize productivity, ultimately leading to cost savings for manufacturers.Furthermore, the machine is equipped with energy-saving features that make it more environmentally friendly and cost-effective to operate. By reducing energy consumption and optimizing production processes, the new machine helps manufacturers lower their carbon footprint and operating costs, while maintaining high production output.Ziqiang Blow Molding Machine Company has a long-standing reputation for delivering reliable and durable machines. The new blow molding machine is no exception, as it is built to withstand the rigors of continuous production and operate seamlessly for extended periods of time. This ensures that manufacturers can rely on the machine to meet their production demands without experiencing frequent breakdowns or maintenance issues.In line with Ziqiang Blow Molding Machine Company’s commitment to customer satisfaction, the new machine also comes with comprehensive after-sales support. The company offers training and technical assistance to help operators maximize the performance of the machine, as well as prompt maintenance and spare parts services to minimize downtime and keep production running smoothly.With its latest innovation, Ziqiang Blow Molding Machine Company is poised to further solidify its position as a leading provider of blow molding technology. The company’s dedication to technological advancement and customer satisfaction reaffirms its commitment to meeting the evolving needs of the industry and supporting manufacturers in achieving their production goals.The new blow molding machine is set to be a game-changer for manufacturers seeking reliable, efficient, and high-performance production solutions. With its advanced features, user-friendly interface, and exceptional durability, it is expected to set a new standard for blow molding machines and empower manufacturers to elevate their production capabilities.As the industry continues to evolve, Ziqiang Blow Molding Machine Company remains at the forefront of innovation, driving the advancement of blow molding technology and empowering manufacturers to thrive in a competitive market. With its latest offering, the company is set to leave a lasting impact on the industry and empower manufacturers to achieve new heights of success.

Latest Technology in Blow Moulding Machines Enhance Productivity and Efficiency

Pet Blow Moulding Machine Enhances Production Quality and CapacityWith the continuous growth of the packaging industry, the demand for high-quality and durable plastic containers in different sizes and shapes has been increasing rapidly. In response to this, many manufacturers have invested in new technologies and equipment to increase production efficiency and quality standards. One such technology that has revolutionized the packaging industry is the Pet Blow Moulding Machine.Pet Blow Moulding Machine is a cutting-edge technology that is used to manufacture plastic containers of different shapes and sizes. This machine works by heating and stretching a preform (a tube of plastic) until it reaches the desired shape and size. The three main types of Pet Blow Moulding Machines are the Injection Stretch Blow Moulding Machine (ISBM), Extrusion Blow Moulding Machine (EBM), and Injection Blow Moulding Machine (IBM). Each type has its own unique features and benefits depending on the production requirements.The Pet Blow Moulding Machine has become a preferred choice for manufacturers in the packaging industry because it offers several advantages over other traditional manufacturing methods. Firstly, this technology is easy to operate and maintain, requiring minimal supervision and less downtime. This makes it possible for manufacturers to produce plastic containers in large quantities within a short time, meeting the increasing demand for their products.Secondly, the Pet Blow Moulding Machine produces high-quality containers with uniform thickness and consistent shapes. The machines are equipped with advanced automation systems that monitor, control and track the production process, ensuring consistent and reliable output. This has significantly reduced the rejection rate of defective plastic containers, saving manufacturers time and resources that would otherwise be wasted in sorting out sub-standard products.Thirdly, the Pet Blow Moulding Machine is highly flexible and can produce plastic containers of various shapes, sizes, and colors. This makes it possible for manufacturers to customize their designs to meet the specific needs of their customers, making them stand out in a highly competitive market. With the Pet Blow Moulding Machine, manufacturers can produce containers for different applications such as food and beverages, cosmetics, pharmaceuticals, and household goods.One company that has leveraged the benefits of the Pet Blow Moulding Machine to enhance its production quality and capacity is X company. This company is a leading manufacturer of plastic containers in the Philippines, specializing in the production of PET bottles, jars, and containers for various industries. They have invested in the latest Pet Blow Moulding Machines, including the ISBM, IBM, and EBM, to increase their production efficiency and quality standards.According to the company's spokesperson, "Our investment in the Pet Blow Moulding Machine has significantly improved our production capacity and quality standards. We can produce high-quality plastic containers in large quantities within a short time, reducing lead times and meeting the increasing demand for our products. The machines are easy to operate and maintain, and we have experienced less downtime since we acquired them."The spokesperson further added, "Our Pet Blow Moulding Machines produce consistent and uniform containers with a high level of accuracy, meeting the strict quality standards of our clients. We can also produce plastic containers of various sizes, shapes, and colors, which has enabled us to expand our product range and explore new market opportunities."In conclusion, the Pet Blow Moulding Machine has revolutionized the packaging industry by offering manufacturers an easy-to-use, high-quality, and reliable manufacturing method. This technology has enhanced production capacity, reduced rejection rates, and increased flexibility for manufacturers, making it a preferred choice for the production of plastic containers. The investment by X Company in these machines demonstrates the value of this technology in the packaging industry and how it can drive business growth and success.