High-Quality Blow Molding Machine Making Waves in China

By:Admin

[Company] has a rich history and extensive experience in the manufacturing of blow molding machines. With a commitment to quality and customer satisfaction, the company has gained a strong reputation for producing reliable and efficient machines. The company's state-of-the-art manufacturing facilities are equipped with advanced technology, allowing for the production of high-precision and high-performance machines.

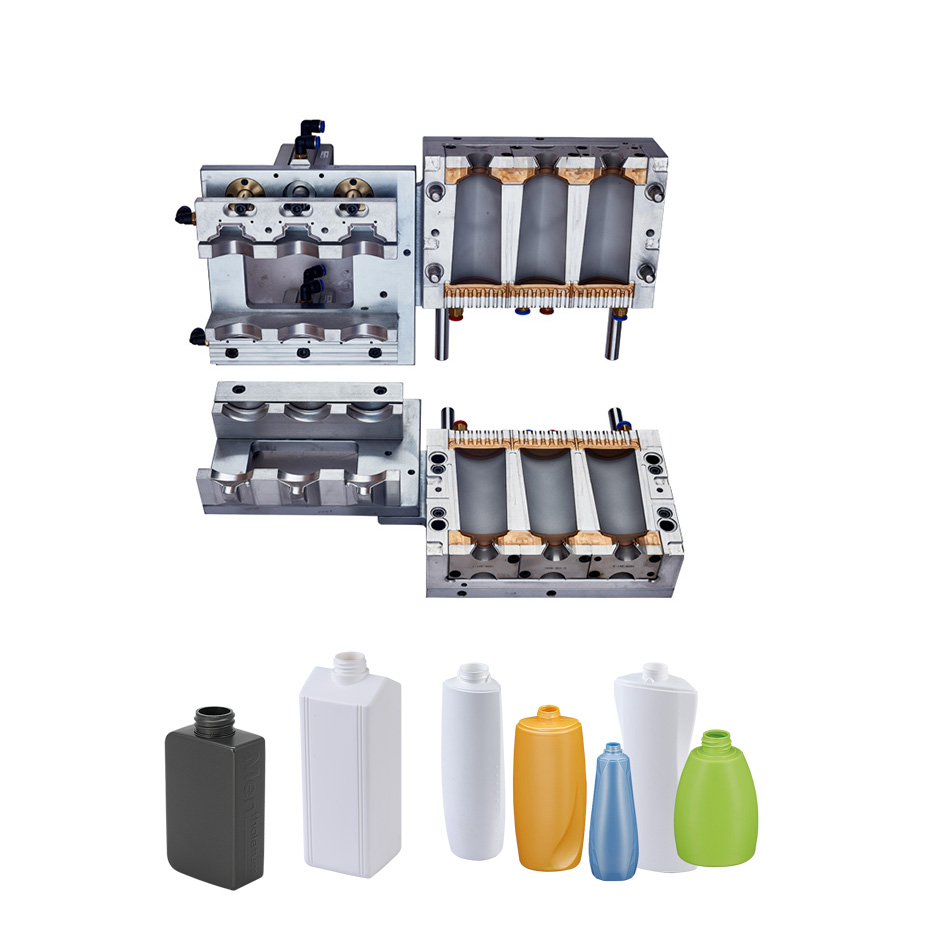

The blow molding machines manufactured by [Company] are designed to offer versatility and performance, catering to a wide range of applications in industries such as packaging, automotive, pharmaceuticals, and consumer goods. The company's machines are capable of producing a diverse array of plastic products, including bottles, containers, and industrial components, with precision and efficiency.

One of the key factors that set [Company] apart from its competitors is its focus on research and development. The company has a dedicated team of engineers and technicians who are continuously working on improving and enhancing their machines to meet the ever-changing needs of the industry. By leveraging the latest advancements in technology, [Company] is able to offer cutting-edge solutions that are not only efficient and reliable but also environmentally friendly.

In addition to their commitment to innovation, [Company] places a strong emphasis on customer service. The company works closely with its clients to understand their specific requirements and provide customized solutions that meet their unique needs. With a global network of distribution and service partners, [Company] ensures that its customers receive comprehensive support and assistance, from the initial installation of the machines to ongoing maintenance and technical support.

The recent market trends have shown a significant increase in the demand for blow molding machines in China, and [Company] is well-positioned to capitalize on this growth. With a strong focus on quality, innovation, and customer satisfaction, the company is poised to continue its leadership in the industry and expand its presence in the global market.

As the demand for plastic products continues to rise across various industries, the importance of reliable and efficient blow molding machines cannot be overstated. With its proven track record of delivering high-quality solutions, [Company] stands as a testament to the commitment and capability of Chinese manufacturers in meeting the evolving needs of the market. [Company] is well-equipped to lead the industry into the future, and its dedication to innovation and customer satisfaction will undoubtedly solidify its position as a premiere provider of blow molding machines in China and beyond.

Company News & Blog

A Detailed Look at the Advantages of Injection Stretch Blow Molding Machine

Injection Stretch Blow Molding Machine Revolutionizes Bottle Manufacturing[City, Date] - The global plastic packaging industry is undergoing a paradigm shift with the introduction of innovative technologies like the Injection Stretch Blow Molding Machine (ISBM). This groundbreaking machine has the potential to revolutionize bottle manufacturing, providing unparalleled efficiency and quality in the production process.ISBM, developed by an industry-leading company with expertise in plastic machinery, combines the efficiency of injection molding with the versatility of stretch blow molding, eliminating the need for separate processes. The machine seamlessly integrates injection, cooling, conditioning, and blow molding, resulting in faster production cycles and a significant reduction in production cost.The ISBM machine consists of three key components: injection molding, conditioning, and stretch blow molding. The injection molding mechanism melts the plastic material and injects it into a mold cavity, creating the preform shape. The conditioning module then cools and conditions the preform to ensure optimal stretching characteristics. Finally, the stretch blow molding stage stretches the preform to its required shape and size, producing high-quality bottles with superior finish and durability.What sets the ISBM apart from conventional methods is its ability to mold the bottle directly from the molten plastic material, eliminating the need for intermediate steps like cooling and solidifying the material before molding. This eliminates production bottlenecks and increases the overall efficiency of the manufacturing process.The ISBM machine also offers tremendous design flexibility, enabling manufacturers to create bottles of various shapes, sizes, and volumes with ease. Its precise control over the molding process ensures consistent wall thickness and impeccable surface finish, meeting the stringent quality standards of the packaging industry.Furthermore, the ISBM machine reduces wastage by minimizing material consumption and optimizing the use of resources. Its sophisticated automation system ensures precise control over material distribution, minimizing the risk of defects and rejects. This not only contributes to a sustainable manufacturing process but also leads to cost savings for manufacturers.The advent of the ISBM machine has the potential to bring about transformative changes in the plastic packaging industry. With its advanced technology and streamlined production process, manufacturers can expect increased productivity, improved product quality, and reduced time-to-market for their bottle products.Company Background:{Insert company name}, the innovator behind the ISBM machine, is a leading supplier of plastic packaging machinery with a global presence. With decades of experience and a strong commitment to technological advancements, {company name} has become a trusted partner for numerous manufacturers in the packaging industry.The company's dedication to research and development has enabled it to develop cutting-edge solutions that address the evolving needs of the market. Its team of highly skilled engineers and technicians work tirelessly to design and manufacture state-of-the-art machinery, ensuring customer satisfaction and industry-leading performance.{Company name}'s core values are centered around sustainability, efficiency, and innovation. The company takes pride in its contribution to a greener future by developing technologies that reduce environmental impact while maintaining high productivity and quality standards.In conclusion, the Injection Stretch Blow Molding Machine represents a groundbreaking advancement in bottle manufacturing. With its integrated production process, design flexibility, and efficiency gains, this innovative technology has the potential to reshape the plastic packaging industry. As more manufacturers embrace this technology, we can expect a more sustainable, cost-effective, and high-quality future for plastic bottle production.

Affordable Second Hand Pet Blowing Machines Available Now

Pet Blowing Machine Second Hand: A Cost-Effective Solution for Your Bottling BusinessThe bottling industry is one of the largest in the world, and it is constantly growing. With this growth, the production of plastic bottles has become increasingly important in the industry. However, buying new equipment can be expensive, and not all businesses can afford this. Luckily, there is a solution: a second-hand pet blowing machine.What is a Pet Blowing Machine?A pet blowing machine is a type of equipment used to produce plastic bottles. The machine uses a process called "stretch blow molding," which involves stretching a tube of heated plastic until it reaches the desired shape and size. The plastic used in these machines is a type of polyester known as polyethylene terephthalate, or PET.Why Consider a Second-Hand Pet Blowing Machine?Purchasing a second-hand pet blowing machine can be a great option for businesses looking to save money on their bottling processes. These machines are typically sold at a lower price than new ones, making them a cost-effective option for businesses that are just starting out or working with a tight budget.Another advantage of purchasing a second-hand pet blowing machine is that they are often tested and inspected by their previous owners before being resold. This means that the machines are usually in good working order and can perform as well as their new counterparts.Finally, investing in a second-hand pet blowing machine can be an environmentally friendly choice. By purchasing a used machine, businesses are helping to reduce the amount of waste in landfills by prolonging the life of a machine that may have otherwise been discarded.Where to Purchase a Second-Hand Pet Blowing Machine?When looking to purchase a second-hand pet blowing machine, it is important to choose a reputable dealer. One such dealer is aptly named "The Pet Blowing Machine Company," which specializes in the sales of Pet Blowing Machines New and Second Hand. With a wide variety of machines available, they can help businesses find the right machine to fit their specific needs. The company offers machines from top brands in the industry and provides a comprehensive service, which includes installation, testing, and maintenance.Company Introduction:The Pet Blowing Machine Company has been in the PET blowing industry for over 20 years. Our experience and knowledge in this field allow us to offer expertise in everything from selecting the right machine to after-sales services. We supply machines for water, carbonated drinks, juices, and other non-edible liquids. We are also experts in reverse osmosis water treatment plants, bottle filling lines, labeling, and packaging machines.At The Pet Blowing Machine Company, we believe in providing our customers with the highest quality of products and services. With our experienced and friendly staff, we aim to exceed our customer's expectations every time. We are dedicated to providing cost-effective solutions for businesses of all sizes, from small start-ups to large corporations. Conclusion:A second-hand pet blowing machine can be a cost-effective and environmentally friendly solution for businesses looking to expand their bottling operations without breaking the bank. Purchasing a machine from a reputable dealer such as The Pet Blowing Machine Company ensures that you will receive a quality used machine that has been tested and inspected. With their comprehensive range of machines and services, they can help businesses find the perfect solution to suit their individual needs.

150 Litre Blow Molded Pots: A Game-Changer in Gardening Solutions

Blow Molded 150 Litre Pots Revolutionize the Gardening Industry[Company Name], a leader in innovative gardening solutions, has recently introduced their latest product, the Blow Molded 150 Litre Pots. These revolutionary pots are set to transform the gardening landscape by providing growers with a durable and efficient solution to cultivate their plants.With a focus on sustainability and meeting the demands of modern gardening enthusiasts, [Company Name] has developed these blow molded pots to cater to the needs of both amateur and professional growers alike. The pots boast a large capacity of 150 liters, providing ample space for plants to grow and thrive.One of the key features that sets the Blow Molded 150 Litre Pots apart is their construction. Manufactured using state-of-the-art blow molding technology, these pots are made from high-quality, durable materials that will withstand the test of time. The blow molding process ensures uniform thickness, making the pots resistant to cracking, chipping, and breaking.Furthermore, the Blow Molded 150 Litre Pots are designed with reinforced rims and sturdy handles, allowing for easy maneuverability even when filled with soil and fully grown plants. This user-friendly design makes it convenient for gardeners to move their plants as needed, whether for optimizing sunlight exposure or reorganizing their garden layout.In addition to their excellent durability and functionality, these pots also prioritize plant health and growth. The Blow Molded 150 Litre Pots feature a unique drainage system that ensures proper water distribution, preventing waterlogging and root rot. The pots also have ample breathing holes to promote healthy root development and airflow, creating an optimal growing environment for plants.The large capacity of the Blow Molded 150 Litre Pots makes them ideal for growing a variety of plants, including trees, shrubs, and fruits. Whether used in small home gardens or large-scale horticultural operations, these pots offer growers the versatility they need to cultivate a wide range of plant species.Furthermore, [Company Name] is committed to environmental sustainability. The Blow Molded 150 Litre Pots are made from recycled materials, reducing waste and carbon footprint. By choosing these pots, gardeners can actively contribute to the preservation of the environment while enjoying the benefits of an efficient and long-lasting gardening solution.According to [Company Name]'s spokesperson, "We are thrilled to introduce the Blow Molded 150 Litre Pots to the market. This product represents our dedication to providing innovative solutions that meet the needs of gardening enthusiasts while prioritizing sustainability. We believe these pots will greatly enhance the gardening experience for both professionals and amateurs alike."The Blow Molded 150 Litre Pots are now available for purchase on [Company Name]'s website and selected gardening retailers. As the gardening industry continues to evolve, [Company Name] remains at the forefront, ensuring that growers have access to innovative and sustainable solutions that drive their passion for gardening forward.

Newly Developed Table Scissor Type Utilizes Blow Moulding Technique

Title: Innovative Blow-Moulded Table Scissor Type Revolutionizes Portable Furniture IndustryIntroduction:In a groundbreaking move, a renowned company has unveiled its latest invention, the Blow-Moulded Table Scissor Type, which promises to revolutionize the portable furniture industry. With its groundbreaking design and multifunctional features, this product is set to redefine convenience and portability for consumers worldwide.Overview of the Blow-Moulded Table Scissor Type:The Blow-Moulded Table Scissor Type is the brainchild of a leading manufacturer renowned for its high-quality and innovative products. This company has established a reputation for pushing the boundaries of design, functionality, and practicality. The Blow-Moulded Table Scissor Type stands as a testament to their commitment to delivering cutting-edge solutions to modern-day consumer needs.Design and Features:This revolutionary table is crafted using state-of-the-art blow-moulding technology, providing a durable and lightweight solution. Its scissor-type folding mechanism ensures easy and hassle-free set-up and collapses to a compact size for effortless transportation and storage. Made from high-grade materials, this table is resistant to weather conditions, ensuring durability in both indoor and outdoor settings.The table's surface boasts a smooth and easy-to-clean polyethylene finish, making it an excellent choice for use in various settings, such as picnics, camping trips, outdoor events, and even indoor gatherings. With its sturdy construction and dependable locking mechanism, users can confidently place heavy items without any concerns about stability.Versatile Applications:The Blow-Moulded Table Scissor Type caters to an array of needs, making it a versatile addition to any lifestyle. Its generous dimensions accommodate multiple users comfortably, suitable for enjoying meals, playing games, or hosting gatherings. The table's adjustable height feature further adds to its versatility, allowing users to customize it according to their preferences or needs.This portable table is designed to enhance convenience and adaptability, offering individuals a practical solution for an array of scenarios. Its multipurpose nature allows it to double as a work station, study desk, or even a temporary display area for commercial purposes.Market Impact:The introduction of the Blow-Moulded Table Scissor Type is set to have a significant impact on the portable furniture market. Its innovative design and adaptability fulfill customers' demand for practical and reliable solutions. This product makes a strong case for replacing traditional heavy and cumbersome tables that are currently dominant in the market.With its lightweight and collapsible design, the Blow-Moulded Table Scissor Type appeals to a wide range of consumers, including outdoor enthusiasts, event organizers, and anyone in need of portable furniture solutions. Moreover, its robust construction ensures a long lifespan, reducing waste and contributing to sustainable consumption patterns.Conclusion:The Blow-Moulded Table Scissor Type represents a major leap forward in portable furniture technology, with its innovative design and versatile range of applications. By combining durability, convenience, and aesthetic appeal, this product aims to enhance users' quality of life and redefine the standards for portable furniture in various settings.With the introduction of this extraordinary table, the company reinforces its commitment to developing innovative solutions that cater to the evolving needs of consumers. By pushing the boundaries of design and functionality, this renowned manufacturer has solidified its position as an industry leader.As the Blow-Moulded Table Scissor Type hits the market, consumers can look forward to a more convenient and practical way of enjoying endless possibilities for outdoor and indoor activities.

Expert Tips for Molding Pet Plastic: What You Need to Know

Molding Pet Plastic, a leading manufacturer of high-quality plastic products, is continuously innovating and expanding its product line to meet the growing demand in the market. With a strong focus on sustainability and customer satisfaction, the company has been at the forefront of the industry for several years.Established in [year], Molding Pet Plastic has swiftly grown to become one of the most trusted names in the plastic manufacturing industry. The company prides itself on its state-of-the-art facilities, cutting-edge technology, and a team of highly skilled professionals who are dedicated to delivering top-notch products to customers worldwide.Specializing in the production of PET (polyethylene terephthalate) plastic products, Molding Pet Plastic offers a wide range of items including bottles, containers, jars, and custom-designed packaging solutions. The company's commitment to quality and innovation has earned it a strong reputation as a preferred supplier for a diverse range of industries including food and beverage, pharmaceuticals, personal care, and household products.In line with the increasing global demand for environmentally friendly solutions, Molding Pet Plastic has placed a strong emphasis on sustainable manufacturing practices. The company has implemented various initiatives to reduce its carbon footprint and minimize environmental impact. By utilizing recycled materials and optimizing production processes, Molding Pet Plastic is actively contributing to a greener and more sustainable future.Furthermore, the company is devoted to the concept of circular economy, where products are designed with recyclability in mind, thus ensuring that they can be repurposed or reused at the end of their life cycle. This commitment to sustainability aligns with the growing consumer preference for eco-friendly products and places Molding Pet Plastic at the forefront of the industry's transition towards a more sustainable and responsible approach to manufacturing.In addition to its focus on sustainability, Molding Pet Plastic continually invests in research and development to stay ahead of market trends and consumer preferences. The company's dedicated team of engineers and designers works closely with clients to create custom packaging solutions that are not only functional and visually appealing, but also meet the highest standards of quality and performance.With a global presence and an extensive network of distributors, Molding Pet Plastic is well-positioned to serve the needs of clients across various industries and regions. The company's commitment to excellence, combined with its ability to tailor solutions to specific requirements, has earned it the trust and loyalty of a diverse customer base.As Molding Pet Plastic continues to grow and expand its product offerings, the company remains steadfast in its core values of quality, innovation, and sustainability. By leveraging its expertise and resources, Molding Pet Plastic is set to continue leading the way in the plastic manufacturing industry, while also making a positive impact on the environment and society as a whole.In conclusion, Molding Pet Plastic stands as a beacon of excellence in the plastic manufacturing industry, with a strong commitment to sustainability, innovation, and customer satisfaction. With a track record of delivering high-quality products and a focus on driving positive change, the company is well-positioned to stay ahead of industry trends and remain a trusted partner for businesses looking for top-notch plastic packaging solutions.

Growing Demand for Plastic Pallets in China's Manufacturing Industry

China Palet Mold and Plastik Palet Join Forces to Offer Comprehensive Packaging SolutionsChina Palet Mold and Plastik Palet, two leading manufacturers of plastic pallets, have come together to provide customers with a wide range of comprehensive packaging solutions. The merger will allow them to leverage their combined strengths in design, engineering, and manufacturing to fulfill the diverse needs of industries across different sectors.The partnership between the two companies has been in the making for a while, and has now culminated in a collaboration that will enable them to offer an expanded range of products and services to their clients. Both companies have established themselves as experts in the production of high-quality plastic pallets, which are the backbone of supply chains across different industries.China Palet Mold, founded in 2001, is a Shenzhen-based company that specializes in the design, development, and manufacture of plastic injection molds for a variety of applications. The company has a state-of-the-art facility that encompasses over 30,000㎡ and employs around 350 staff members, including engineers, technicians, and skilled workers. The company's core focus is on providing customers with customized mold solutions that meet their specific requirements.Plastik Palet, on the other hand, is a Turkish company that has been operating since 1982, and has established itself as a leading manufacturer of plastic pallets in the European market. The company's products are used in various industries, including automotive, food and beverage, pharmaceuticals, and logistics. Plastik Palet has a wide range of products that can accommodate different operational requirements, from lightweight pallets to heavy-duty ones that can handle extreme conditions.The partnership between China Palet Mold and Plastik Palet is expected to offer significant benefits to customers looking for high-quality packaging solutions that meet their unique needs. By combining their expertise, they will be able to offer a wider range of products and services that cater to different industries' needs. For example, Plastik Palet's products can now be customized with molds developed by China Palet Mold, resulting in an even greater range of customized solutions for clients.The joint venture also enables the two companies to share valuable resources, including research and development, engineering, and manufacturing capabilities. This will result in a more efficient and streamlined operation that will enable them to better respond to customer demands, reduce lead times, and improve customer service.In a statement announcing the partnership, the CEOs of the two companies expressed their excitement for the collaboration, emphasizing their commitment to providing customers with the best quality products and services. "We are thrilled to have the opportunity to work together and leverage each other's strengths to offer our clients an even greater range of packaging solutions," said China Palet Mold CEO. "We believe that this partnership will enhance our ability to deliver top-notch products and services to our customers across the globe," added Plastik Palet's CEO.With the joint venture, China Palet Mold and Plastik Palet will continue to set the standard for quality, innovation, and customer service in the plastic pallet manufacturing industry. As they bring their expertise and resources together, customers can expect new and exciting developments as they work to offer the most comprehensive packaging solutions possible.

High-quality Automatic Pet Bottle Blow Molding Machine for Efficient Production

Automatic Pet Bottle Blow Molding Machine Revolutionizes Production in the Beverage IndustryThe beverage industry is one of the most competitive and fast-paced sectors of the global market. In order to keep up with the demand for high-quality products, companies need cutting-edge technology to streamline their production processes. This is where the innovative Automatic Pet Bottle Blow Molding Machine comes in, offering a revolutionary solution to the challenges faced by beverage manufacturers.This state-of-the-art machine, developed by a leading technology company in the field of industrial automation, is designed to meet the growing demand for efficient and cost-effective production of PET bottles. The machine features advanced technology that allows for precise and consistent molding of PET bottles, resulting in a superior quality product that meets the highest industry standards.The Automatic Pet Bottle Blow Molding Machine is equipped with a range of intelligent features that set it apart from traditional blow molding machines. It utilizes advanced PLC control technology and a user-friendly interface, allowing operators to easily set and monitor the machine's parameters in real time. This ensures greater accuracy and efficiency in the production process, reducing the risk of errors and minimizing downtime.In addition, the machine is equipped with a high-speed and high-precision mold clamping system, which ensures a fast and stable molding process. This enables beverage manufacturers to significantly increase their production capacity while maintaining the quality and integrity of the final product. The machine's modular design also allows for easy maintenance and servicing, further reducing downtime and production costs.Furthermore, the Automatic Pet Bottle Blow Molding Machine is designed to be highly flexible, capable of producing a wide range of bottle sizes and shapes to meet the diverse needs of beverage manufacturers. Whether it's standard PET bottles, custom-designed containers, or specialty shapes, this machine can accommodate a variety of production requirements, making it an invaluable asset for companies looking to stay ahead in the competitive beverage market.The company behind this groundbreaking technology has a long-standing reputation for innovation and excellence in the field of industrial automation. With a strong focus on research and development, their team of engineers and experts have continuously pushed the boundaries of technology to create solutions that address the evolving needs of the market. By leveraging their expertise and industry knowledge, they have successfully developed the Automatic Pet Bottle Blow Molding Machine as a game-changing solution for beverage manufacturers around the world.As a result, the machine has already garnered significant attention and accolades from industry professionals and experts. Its ability to significantly improve production efficiency, reduce costs, and enhance product quality has positioned it as a must-have technology for companies looking to optimize their production processes and gain a competitive edge in the beverage market.In conclusion, the Automatic Pet Bottle Blow Molding Machine is a transformative technology that is revolutionizing the production of PET bottles in the beverage industry. With its advanced features, flexibility, and user-friendly design, it offers a cost-effective and efficient solution for companies looking to meet the growing demand for high-quality beverage products. As the industry continues to evolve, this innovative machine is set to play a crucial role in shaping the future of beverage manufacturing, setting new standards for efficiency, quality, and innovation.

36" Jesus Joseph Blow Mold: News and Updates

Blow Mold 36" Jesus Joseph is a new product that has been making waves in the market. This unique decoration is perfect for Christmas and is sure to be a hit with those looking to add a touch of religious symbolism to their festivities.With a company introduction, {} is a leading supplier of decorations and home accessories. The company has a strong reputation for providing high-quality products that are both visually stunning and durable. With a focus on innovation and trendsetting, {} is constantly striving to bring new and exciting products to the market.The Blow Mold 36" Jesus Joseph is a perfect example of the company's commitment to innovation. This beautiful decoration features a stunning depiction of Jesus and Joseph, perfect for adding a touch of religious significance to any holiday celebration. The intricate details and lifelike appearance of the figures make them perfect for use in a variety of settings, from outdoor displays to indoor decorations.One of the most remarkable aspects of this product is its durability. Made from high-quality materials, the Blow Mold 36" Jesus Joseph is designed to withstand the elements, ensuring that it can be enjoyed year after year. This makes it a fantastic investment for anyone looking to add a lasting touch of beauty and tradition to their holiday celebrations.In addition to its visual appeal and durability, the Blow Mold 36" Jesus Joseph is also incredibly easy to set up and use. The figures come with a built-in stand, making them simple to display in any location. Whether you're looking to create a stunning outdoor nativity scene or add a religious touch to your living room, this product is versatile and easy to work with.When asked about the inspiration behind the Blow Mold 36" Jesus Joseph, a spokesperson for {} shared, "We wanted to create a product that would help people celebrate the true spirit of Christmas. With so many decorations focusing on Santa Claus and other secular symbols, we saw a need for beautiful, high-quality religious decorations that would allow our customers to share their faith and traditions with their families and communities."The spokesperson went on to add, "The Blow Mold 36" Jesus Joseph is the result of months of hard work and dedication, and we're incredibly proud of the final product. We believe that it will make a fantastic addition to any holiday celebration and help to remind people of the true meaning of Christmas."Feedback from customers has been overwhelmingly positive, with many praising the attention to detail and lifelike appearance of the figures. "I was blown away by the quality of the Blow Mold 36" Jesus Joseph," one customer commented. "It looks so realistic, and the fact that it's so durable means that I'll be able to enjoy it for years to come. It's the perfect addition to my Christmas decorations."With its combination of beauty, durability, and religious significance, the Blow Mold 36" Jesus Joseph is sure to become a staple in holiday decorations. Whether used as the centerpiece of an outdoor nativity scene or as a focal point in a living room display, it is a wonderful way to celebrate the true meaning of Christmas.As the holiday season approaches, {} is excited to offer this stunning new product to its customers. With a reputation for quality and a dedication to bringing innovative and beautiful products to the market, the company is confident that the Blow Mold 36" Jesus Joseph will be a huge success. Whether you're looking to add a touch of religious symbolism to your holiday celebrations or simply want to invest in a high-quality decoration, this product is a fantastic choice.

Discover the Advantages of Tri-Cavity Blow Molding for PET Products

Molde 3 Cavidades Soplado PET Introduces a Revolutionary Solution for PackagingMolde 3 Cavidades Soplado PET, one of the leading manufacturers of PET packaging in the world, recently introduced a new line of products that promises to revolutionize the packaging industry. The company has developed a new technology that allows for the production of PET bottles with three cavities instead of the traditional one or two cavities. This innovation not only promises to cut down production time and increase efficiency, but also offers several other benefits for both manufacturers and consumers alike.The new technology developed by Molde 3 Cavidades Soplado PET has been designed to address some of the major challenges faced by the packaging industry. One of the key problems faced by manufacturers is the need for quick and efficient production of high-quality packaging. With the new three-cavity technology, the manufacturing process is significantly streamlined, reducing production time by up to 30%. This means that manufacturers can produce more bottles in less time, leading to increased efficiency and profitability.In addition to faster production times, Molde 3 Cavidades Soplado PET's new technology also offers several other benefits. The three cavities in the PET bottles provide greater strength and durability, making them less prone to breaking or cracking during transport. This is a major advantage for both manufacturers and consumers, as it reduces the risk of wastage and decreases the need for re-packaging.Furthermore, PET bottles produced with the new three-cavity technology also offer greater flexibility and customization options. Manufacturers can create bottles with different shapes and sizes, ranging from small travel-sized bottles to larger containers for bulk purchases. This allows companies to cater to a wider range of customer needs, ultimately driving growth and profitability.Molde 3 Cavidades Soplado PET's new three-cavity technology is also more environmentally sustainable than traditional PET bottles. By reducing the need for re-packaging and improving durability, the use of the new technology can lead to a significant decrease in plastic waste. Additionally, the company uses recyclable materials in the production of its PET bottles, further promoting sustainability and eco-friendliness.The introduction of the new three-cavity technology by Molde 3 Cavidades Soplado PET has been met with great enthusiasm from the packaging industry. Several manufacturers have already expressed interest in the technology and are planning to incorporate it into their production processes. The new technology is expected to drive growth and innovation in the industry, offering a competitive advantage for companies that adopt it.Molde 3 Cavidades Soplado PET is a highly reputable company dedicated to the production of high-quality PET bottles. Their commitment to innovation and sustainability has made them a leader in the industry, with their products being used by some of the largest companies in the world. With the introduction of their new three-cavity technology, Molde 3 Cavidades Soplado PET is poised to continue its growth and leadership in the industry, bringing cutting-edge solutions to manufacturers and consumers alike.In conclusion, Molde 3 Cavidades Soplado PET's new three-cavity technology is a game-changer for the packaging industry. It offers several advantages, including faster production times, greater durability, and greater flexibility and customizability. Furthermore, the technology is environmentally sustainable, promoting the reuse of materials and reducing plastic waste. With its commitment to innovation and sustainability, Molde 3 Cavidades Soplado PET is poised to continue its leadership in the industry and drive growth and profitability for manufacturers and consumers alike.

New Mould Designs for Bubble Caps

Bubble Cap Mould: An Essential Tool for the Chemical IndustryBubble cap moulds are essential for the chemical industry. They are used to manufacture a wide range of products that are ubiquitous in our daily lives. From household cleaners to plastics, bubble cap moulds are used to make the caps that seal these products.Bubble cap moulds are the cornerstone of many industries and are manufactured by only a few companies worldwide. One such company that produces bubble cap moulds is headquartered in China. This company specializes in the design and manufacture of various types of moulds and has been in the industry for over 20 years.Bubble cap moulds are typically made of high-quality stainless steel. The process begins by designing the mould, which takes into account factors such as the dimensions and shape of the cap, as well as other specifications such as the material of the cap and the temperature and pressure conditions under which it will be produced.The design is then manufactured using CNC machines with high precision to ensure that the mould conforms to the exact specifications. Once the mould is completed, it is subjected to rigorous testing to ensure that it is of the highest quality standard.The chemical industry relies heavily on bubble cap moulds to produce a variety of products. Chemical companies use bubble caps to produce a variety of products, including various chemicals, household cleaners, and plastics, among others. Bubble caps are also used in the production of medical equipment, ensuring that the products are sterile and free from contamination.Bubble cap moulds are highly versatile and can be customized to fit the specific needs of each industry. They can be designed to work under varying pressure and temperature conditions and can be adapted to produce different types of caps, including twist-off and snap-on caps.One of the biggest advantages of using bubble cap moulds is their high precision. Bubble cap moulds are designed to produce caps at a high precision level, ensuring that the caps meet strict quality control standards. This level of precision also ensures that the caps are consistent in size, shape, and quality, which is important in maintaining product integrity.Moreover, bubble cap moulds are highly efficient. The moulds are designed to produce multiple caps at once, which saves a significant amount of time. This efficiency is particularly important in the chemical industry, where large volumes of products need to be produced quickly and efficiently.The Chinese company offers a wide range of bubble cap moulds to meet the needs of various industries. They specialize in producing high-quality bubble cap moulds that meet the strictest quality standards. The company has a team of highly skilled engineers and technicians who are equipped with state-of-the-art equipment to ensure the best quality products.In addition to the production of bubble cap moulds, the company offers a comprehensive range of services, including design and development, customization, repair, and maintenance. The team is available to provide technical support and advice to clients, ensuring that they get the best products and services.In conclusion, bubble cap moulds are an essential tool in the chemical industry. They are used to manufacture a wide range of products, including various chemicals, household cleaners, and plastics, among others. The Chinese company specializes in the production of high-quality bubble cap moulds that are designed to meet the strictest quality standards. With over 20 years of experience in the industry, the company offers a wide range of services, including design and development, customization, repair, and maintenance. Their team of highly skilled engineers and technicians ensures the best quality products and services, making them a valuable resource for clients in the chemical industry.