High Quality Blow Molding Machine for Pet Bottles: A Comprehensive Guide

By:Admin

The blow molding machine for PET bottles is a crucial piece of equipment in the packaging industry, allowing companies to produce a wide range of bottles and containers for various applications. [Company Name] has continuously invested in research and development to enhance the performance and capabilities of their blow molding machines, staying ahead of the competition and adapting to the evolving needs of the market.

One of the key features of [Company Name]'s blow molding machines is their versatility, allowing for the production of bottles in different shapes, sizes, and designs. This flexibility is crucial for businesses looking to stand out in a competitive market and meet the diverse requirements of their customers. Additionally, [Company Name] integrates state-of-the-art technology into their machines to ensure precision and consistency in the production process, resulting in high-quality bottles that meet industry standards.

Moreover, [Company Name] places a strong emphasis on sustainability, offering solutions that reduce energy consumption and minimize waste in the production of PET bottles. By incorporating eco-friendly practices into their machines, [Company Name] is supporting the global effort to reduce the environmental impact of packaging operations while helping their customers achieve their sustainability goals.

In addition to their commitment to innovation and sustainability, [Company Name] is dedicated to providing exceptional customer support and service. Their team of experts works closely with clients to understand their specific needs and develop customized solutions that meet their production requirements. This level of dedication and collaboration has earned [Company Name] a reputation for reliability and excellence in the industry.

With a global presence, [Company Name] serves a diverse clientele across various industries, including food and beverage, pharmaceuticals, personal care, and more. Their blow molding machines have played a vital role in helping businesses streamline their production processes and deliver high-quality packaging solutions to consumers worldwide.

Looking ahead, [Company Name] remains committed to pushing the boundaries of technology and innovation in the blow molding industry. By staying at the forefront of advancements and market trends, [Company Name] is poised to continue providing cutting-edge solutions that empower businesses to achieve their production goals and meet the demands of a dynamic market.

In conclusion, [Company Name] is a leading manufacturer of blow molding machines for PET bottles, offering state-of-the-art technology, sustainable solutions, and exceptional customer support. With a strong track record of success and a dedication to continuous improvement, [Company Name] is well-positioned to meet the evolving needs of the packaging industry and drive innovation for years to come.

Company News & Blog

Revolutionize Manufacturing with 3D Printed Injection Mold Technology

In the world of manufacturing, the use of advanced technology has become increasingly prevalent, and the latest innovative development comes in the form of 3D Printed Injection Mold from [Company Name]. The company, known for its forward-thinking approach to production, has once again set itself apart by introducing this cutting-edge solution to the industry.[Company Name] is a leading provider of manufacturing and production services, and they are always on the lookout for new ways to improve their processes. With the introduction of 3D Printed Injection Mold, they have once again demonstrated their commitment to staying at the forefront of technological advancement.Traditional injection mold production can be a time-consuming and costly process, often requiring the use of specialized equipment and skilled labor. However, with the advent of 3D printing technology, [Company Name] has found a way to streamline this process and reduce both time and cost.The 3D Printed Injection Mold offers numerous benefits, including faster production times, reduced material waste, and greater design flexibility. By using 3D printing technology, [Company Name] is able to create complex and intricate molds that would have been difficult or impossible to achieve through traditional methods. This innovation allows for more creativity and precision in the design and production of injection molds.Additionally, the use of 3D printing technology in injection mold production allows for rapid prototyping and iteration. This means that [Company Name] can quickly test different mold designs and make changes as needed, ultimately leading to a more efficient and effective manufacturing process.One of the key advantages of 3D Printed Injection Mold is its ability to reduce lead times. Traditional injection mold production can take weeks or even months, but with 3D printing, [Company Name] can significantly reduce the time it takes to create a mold. This not only allows them to meet tight production deadlines but also enables them to respond quickly to changes in design or production requirements.Furthermore, the use of 3D Printed Injection Mold has environmental benefits as well. By reducing material waste and energy consumption, [Company Name] is able to minimize its environmental footprint, contributing to a more sustainable manufacturing process.In addition to its practical benefits, the use of 3D Printed Injection Mold also showcases [Company Name]'s commitment to embracing and leveraging the latest technologies. By investing in cutting-edge solutions, they are positioning themselves as an industry leader and setting a new standard for manufacturing excellence.Overall, the introduction of 3D Printed Injection Mold from [Company Name] represents a significant step forward in the manufacturing industry. By leveraging the power of 3D printing technology, they are able to improve efficiency, reduce costs, and increase design flexibility. This innovation not only benefits [Company Name] but also has the potential to revolutionize the way injection molds are produced across the industry. With their dedication to continuous improvement and innovation, it's clear that [Company Name] will continue to lead the way in the manufacturing sector.

Discover the Advantages of Blow Mold Manufacturing for Your Business

In recent years, the demand for blow mold manufactures has been on the rise. Blow Mold Manufacturers (BMM), a leading company in the industry, has been at the forefront of this trend. Known for their commitment to quality, innovation, and customer satisfaction, BMM has been making waves in the market with their wide range of products and services.Founded in 1992, BMM has come a long way since its inception. With a sprawling manufacturing unit spanning over 200,000 sq. ft., BMM has the capacity to produce over 500 molds per year. The company's state-of-the-art technology, coupled with their experienced and skilled workforce, ensures that each product meets the highest standards of quality.BMM's products are widely used in the packaging industry, with applications in the food and beverage, pharmaceutical, and cosmetics sectors. Their range of products includes blow moldings, injection moldings, extrusion blow moldings, and stretch blow moldings, among others. The company also offers custom molding services, which allows them to cater to the unique needs of their clients.One of the key factors that sets BMM apart from its competitors is their focus on innovation. The company is constantly exploring new avenues and adopting cutting-edge technology to enhance their products and services. Their R&D team works closely with clients to identify their needs and develop customized solutions that meet their requirements.BMM's commitment to customer satisfaction is reflected in their after-sales service. The company has a dedicated team of service professionals that provide round-the-clock support to clients. They also offer maintenance and repair services, ensuring that their products continue to perform optimally even after years of use.Over the years, BMM has built a loyal customer base, with clients ranging from small start-ups to large multinationals. The company's products have been used in a wide range of applications, from packaging for household products to medical devices.As the demand for blow mold manufactures continues to rise, BMM is well-positioned to capitalize on this trend. The company's strong focus on quality, innovation, and customer satisfaction sets them apart from their competitors and makes them a preferred choice for clients.Looking to the future, BMM is poised for growth. The company is exploring new markets and expanding their product range to cater to evolving customer needs. They are also investing in research and development to stay ahead of their competitors and continue to lead the industry.In summary, Blow Mold Manufacturers is a leading company in the blow mold industry. With a focus on quality, innovation, and customer satisfaction, the company has built a loyal customer base and is well-positioned for growth in the years to come. Their commitment to excellence and their dedication to meeting the unique needs of their clients make them a preferred choice for businesses in the packaging industry.

New Technique for Juggling Blow Molded Items Discovered

Blow Mold Juggling, a revolution in the packaging industryIn today's fast-paced world, the packaging industry plays a vital role in delivering products to consumers safely and efficiently. One company leading the way in innovative packaging solutions is {Company Name}. With their dedication to superior quality and cutting-edge technology, they have recently introduced Blow Mold Juggling, a game-changing advancement in the packaging industry.Blow Mold Juggling is a process that involves the use of blow molding technology to create intricate and customized packaging designs. This revolutionary technique allows for the production of lightweight and durable packaging solutions that can cater to a wide range of products. From food and beverages to personal care and homecare products, Blow Mold Juggling offers an unprecedented level of flexibility and creativity in packaging design.{Company Name} has been at the forefront of blow molding technology for over {number} years. With their state-of-the-art facilities and a team of highly skilled engineers and designers, they have consistently pushed the boundaries of what is possible in the packaging industry. The introduction of Blow Mold Juggling is a testament to their commitment to innovation and excellence.The benefits of Blow Mold Juggling are numerous. The process allows for the creation of intricate designs and detailed textures that were previously unachievable with traditional packaging methods. This opens up a world of possibilities for brands looking to create unique and eye-catching packaging that stands out on the shelf. Additionally, the lightweight nature of blow molded packaging reduces transportation costs and environmental impact, making it a sustainable choice for brands looking to minimize their carbon footprint.{Company Name} is proud to offer Blow Mold Juggling as part of their comprehensive packaging solutions. From concept development to final production, they work closely with their clients to bring their vision to life. Whether it's a custom shape, a unique texture, or a specific color, their team of experts is dedicated to delivering packaging solutions that exceed expectations.One of the key advantages of Blow Mold Juggling is its ability to enhance product protection. By creating packaging that perfectly fits the product, brands can minimize the risk of damage during transportation and storage. This not only improves the overall customer experience but also reduces the need for excess packaging materials, further contributing to sustainability efforts.In addition to its functionality, Blow Mold Juggling also offers a high level of brand customization. With the ability to incorporate logos, branding elements, and other visual elements directly into the packaging design, brands can create a seamless and cohesive brand experience for consumers. This level of customization helps to strengthen brand identity and fosters brand loyalty among consumers.{Company Name} is excited to bring Blow Mold Juggling to the market, and they are confident that it will be a game-changer for the packaging industry. With its unparalleled flexibility, sustainability, and brand customization capabilities, Blow Mold Juggling is set to disrupt the way products are packaged and presented to consumers.As the world continues to demand more innovative and sustainable packaging solutions, {Company Name} is committed to leading the way with Blow Mold Juggling. With a strong focus on technological advancements, creative design, and environmental responsibility, they are poised to shape the future of the packaging industry for years to come.

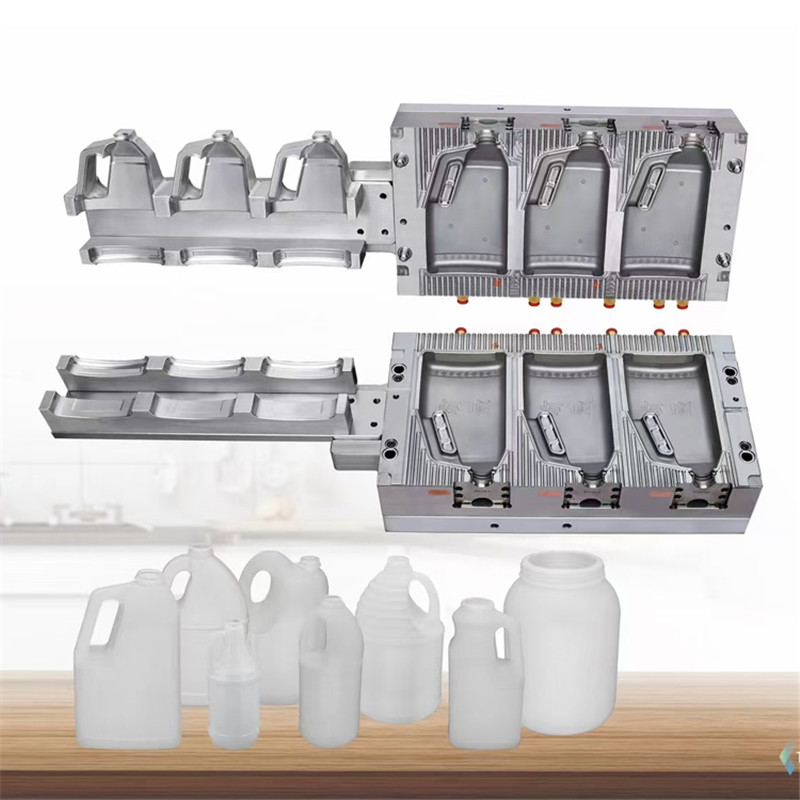

Ultimate Guide to Bottle Blowing Molds: Everything You Need to Know

Title: Innovative Bottle Blowing Mold Revolutionizes Manufacturing ProcessIntroduction:In today's rapidly evolving manufacturing industry, companies are constantly striving to increase efficiency and reduce costs while maintaining the highest quality standards. One company addressing these demands is [Company Name], a leading player in the field of mold manufacturing. Recently, [Company Name] has introduced an innovative bottle blowing mold that promises to revolutionize the production process for numerous industries.[Company Name] is renowned for its constant focus on research and development, investing substantial resources into creating cutting-edge solutions for its clients. With a commitment to staying ahead of market trends, the company has successfully maintained its position as a trusted partner to various manufacturers worldwide.The New Bottle Blowing Mold:The latest achievement by [Company Name] is its state-of-the-art bottle blowing mold, which offers unparalleled benefits to the manufacturing sector. This revolutionary mold has garnered significant attention due to its exceptional design, innovative features, and potential to reshape the way bottles are produced across industries.Innovative Design and Features:The newly introduced bottle blowing mold incorporates several groundbreaking design elements that enhance its functionality and performance. One notable feature is its modular design, allowing for easy customization and adaptation to diverse manufacturing requirements. This design feature ensures optimal efficiency while reducing production costs, making it a highly sought-after solution for manufacturers.Furthermore, the bottle blowing mold incorporates cutting-edge technologies, such as precision control mechanisms that enable consistent and precise bottle shaping. This ensures uniformity in bottle dimensions and quality throughout the production process. By minimizing production variation, [Company Name]'s mold helps manufacturers maintain high-quality standards while improving overall productivity.Implications for Industries:The introduction of [Company Name]'s bottle blowing mold has far-reaching implications for various industries reliant on bottle production. The mold's adaptability enables manufacturers to produce bottles for a wide range of applications, including food and beverage, pharmaceuticals, cosmetics, and household products. This versatility offers manufacturers unprecedented flexibility and reduces the need for multiple molds, optimizing inventory management and cost-effectiveness.Additionally, the mold's precise control mechanism ensures that the produced bottles meet stringent regulatory requirements for safety and product integrity. This eliminates the risk of faulty bottles entering the market, enabling manufacturers to maintain consumer trust and avoid costly product recalls.Benefits for Manufacturers:By adopting [Company Name]'s bottle blowing mold, manufacturers stand to benefit in numerous ways. Firstly, the mold's modular design streamlines the production process, reducing downtime for mold changes and minimizing overall production costs. This not only saves manufacturers money but also enables them to react swiftly to market demands, leading to a competitive edge.Moreover, the consistent mold performance and enhanced product quality achieved through precision control mechanisms contribute to waste reduction and improved overall efficiency. With higher production yields and less material wastage, manufacturers can generate higher profits while minimizing their environmental footprint.Conclusion:[Company Name]'s introduction of the groundbreaking bottle blowing mold signifies a significant step forward in the manufacturing industry. The innovative design, modular flexibility, and precise control mechanisms of this mold offer manufacturers unparalleled efficiency, cost-effectiveness, and product quality. As a result, various industries can benefit from this cutting-edge solution, producing standardized, high-quality bottles to meet consumer demands effectively. [Company Name] continues to exemplify its commitment to providing state-of-the-art solutions, solidifying its position as a leader in mold manufacturing for a global clientele.

The Ultimate Guide to Plastic Injection Blow Molding Techniques

Title: Plastic Injection Blow Molding: Revolutionizing Manufacturing with Unmatched Precision and EfficiencyIntroduction:Modern-day manufacturing relies heavily on technological advancements to optimize productivity and meet the demands of an ever-evolving market. One such groundbreaking innovation is Plastic Injection Blow Molding (PIBM), a process that combines the versatility of plastic injection molding with the efficiency of blow molding. In this article, we will explore the transformative capabilities of PIBM in various industries and its potential implications for businesses.Paragraph 1:Plastic Injection Blow Molding, prominently utilized by Industry-Leading Innovations (ILI), has redefined the manufacturing landscape through its ability to produce complex, high-quality plastic components. By integrating injection molding to create intricate preforms and then using blow molding for final product formation, PIBM delivers superior precision, durability, and design flexibility.Paragraph 2:The strategic partnership between Industry-Leading Innovations and Plastic Solutions Corporation (PSC) has further solidified the position of PIBM as an industry game-changer. Having recognized the need for cutting-edge molding technology in today's market, the collaboration aims to cater to the diverse requirements of numerous industries, including automotive, consumer goods, and healthcare.Paragraph 3:One of the standout features of PIBM is its ability to produce lightweight materials while maintaining exceptional structural integrity. This characteristic makes the process highly suitable for manufacturing automotive components, where reducing weight while ensuring durability is a top priority. The PIBM technique allows for the creation of fuel-efficient vehicles without compromising safety standards.Paragraph 4:Consumer goods manufacturers have also witnessed the remarkable benefits of PIBM. By enabling the production of intricate shapes and designs, PIBM provides unrivaled opportunities for product differentiation. From vibrant packaging to ergonomic handles, manufacturers can enhance brand visibility and customer experience, thus gaining a competitive edge in a crowded marketplace.Paragraph 5:The healthcare industry, driven by a constant need for precision and quality, has embraced PIBM as a transformative manufacturing process. Medical devices and equipment require meticulous attention to detail, and PIBM offers unparalleled control over product specifications, reducing errors and ensuring consistent production. Additionally, PIBM's ability to manufacture single-use medical components with precise tolerances contributes to minimizing contamination and enhancing patient safety.Paragraph 6:Not only does PIBM offer remarkable production capabilities, but it also aligns with sustainability goals. The process eliminates excess material waste by producing components with precise measurements. With its energy-efficient operations and recyclable materials, PIBM contributes to environmental conservation, a crucial consideration for businesses in today's eco-conscious society.Conclusion:Plastic Injection Blow Molding has unlocked immense potential for manufacturers seeking precise, efficient, and sustainable production solutions. The strategic collaboration between Industry-Leading Innovations and Plastic Solutions Corporation paves the way for businesses across various industries to harness the transformative power of PIBM. As market demands continue to evolve, PIBM stands as a testament to the ingenuity and dedication of companies at the forefront of innovation. With its unmatched precision and unrivaled efficiency, PIBM is poised to reshape the future of manufacturing.

Exploring the Benefits and Applications of Blow Mold Films for Various Industries

Blow Mold Film Industry Continues to Thrive: A Detailed Company IntroductionThe blow mold film industry has experienced significant growth over the past few years, with companies like [Company Name] leading the charge. [Company Name] is a renowned player in the blow-molded film manufacturing sector, known for its cutting-edge technology, high-quality products, and dedication to customer satisfaction.With its state-of-the-art facilities and a commitment to innovation, [Company Name] has established itself as a market leader within the blow mold film industry. By consistently investing in research and development, the company has been able to introduce a wide range of films that cater to specific customer requirements.Through their blow mold film technology, [Company Name] has been able to create packaging solutions that offer superior product protection. Their films are not only durable and resilient but also boast excellent moisture, humidity, and chemical resistance. This makes them an ideal choice for customers operating in various sectors, including food and beverages, pharmaceuticals, personal care, and industrial packaging.The blow mold film produced by [Company Name] offers unrivaled versatility. By leveraging their extensive expertise, the company has been able to engineer films that are customizable in terms of thickness, size, and printing options. This flexibility enables customers to create packaging solutions that align perfectly with their specific branding requirements.As consumer preferences change, sustainability has become a key focus for companies across industries. Recognizing this need, [Company Name] has embraced environmentally friendly practices by adopting advanced materials and technologies that reduce the carbon footprint associated with their blow mold film production. By making this transition, they have not only earned the trust of eco-conscious customers but have also contributed to a greener future.Furthermore, [Company Name] places great emphasis on maintaining strong relationships with its customers. The company realizes that client satisfaction is essential for long-term success. To achieve this, they work closely with clients right from the initial consultation stage to final product delivery. This collaborative approach allows them to understand and meet the unique needs of each customer, resulting in tailored solutions that drive mutual success.In order to remain at the forefront of the blow mold film industry, [Company Name] consistently invests in cutting-edge technology and equipment. Their manufacturing facilities are equipped with state-of-the-art machinery, which enables them to meet specific production requirements efficiently. Additionally, the company has established a robust quality control system that ensures every roll of film meets the highest industry standards.To further enhance their market presence and expand their global reach, [Company Name] has also embraced international partnerships. By forming strategic alliances, they have been able to enter new markets and offer their high-quality products and services to a broader customer base.In conclusion, the blow mold film industry continues to thrive, with [Company Name] playing a pivotal role in its growth and development. Through their dedication to technological advancements, excellent product quality, sustainability initiatives, and customer-centric approach, [Company Name] has firmly positioned itself as a leading player in the market. As the industry evolves, [Company Name] remains committed to pushing boundaries and providing innovative solutions to meet the ever-changing needs of their customers.

Festive Blow Mold Santa for Christmas Decorations

The holiday season is officially upon us, and what better way to celebrate than by adorning our homes with festive decorations? One of the most iconic symbols of Christmas is none other than the jolly old man himself, Santa Claus. And what better way to bring Santa into our homes than with a Christmas Blow Mold Santa from [Company Name]?[Company Name] has been a leading provider of high-quality holiday decorations for over two decades. Specializing in bringing the magic of Christmas to life, the company has become a household name for families looking to create a winter wonderland in their own homes. With a wide range of products including trees, lights, and figurines, [Company Name] has established itself as a go-to source for all things Christmas.One of the standout products in [Company Name]'s extensive catalogue is the Christmas Blow Mold Santa. This larger-than-life decoration is designed to be placed outdoors, greeting visitors and passersby with the joyful presence of Santa Claus. Made from durable, weather-resistant materials, this Santa is built to withstand the elements and can be enjoyed for many holiday seasons to come.The Christmas Blow Mold Santa from [Company Name] stands at an impressive height, making it a focal point of any outdoor display. With its classic red suit, rosy cheeks, and a sack of presents on his back, this Santa embodies the timeless charm and warmth of the holiday season. The attention to detail and craftsmanship that goes into each Santa is evident, making it a must-have for anyone looking to spread Christmas cheer.While the Christmas Blow Mold Santa is a stunning addition to any outdoor holiday display, [Company Name] understands that the true magic of Christmas lies in the joy of giving. That's why the company has partnered with local charities and organizations to donate a portion of the proceeds from every Santa sold. By purchasing a Christmas Blow Mold Santa from [Company Name], customers are not only bringing joy to their own homes but also contributing to the well-being of their community.In addition to its charitable initiatives, [Company Name] takes pride in its commitment to sustainability. The company utilizes eco-friendly materials in the production of its decorations and implements environmentally conscious practices throughout its operations. By choosing a Christmas Blow Mold Santa from [Company Name], customers can feel good about their purchase knowing that it aligns with their values of supporting ethical and responsible businesses.As the holiday season approaches, there is no better time to bring the spirit of Christmas into our homes. With the Christmas Blow Mold Santa from [Company Name], families can create lasting memories and share in the joy of the season. Whether placed on the front lawn, by the fireplace, or at a community event, this Santa is sure to bring smiles and laughter wherever it goes.In conclusion, [Company Name]'s Christmas Blow Mold Santa is more than just a decoration; it's a symbol of tradition, generosity, and the magic of Christmas. With its exceptional quality, charitable contributions, and dedication to sustainability, this Santa is a testament to [Company Name]'s unwavering commitment to spreading holiday cheer. As we gather with loved ones and celebrate the most wonderful time of the year, the Christmas Blow Mold Santa serves as a reminder of the joy and warmth that the season brings.

Top Blow Bottle Mold Manufacturer in China Unveils Innovative New Product

China Blow Bottle Mold, a leading manufacturer of bottle molds, has recently developed a new line of cutting-edge blow bottle molds that are set to revolutionize the packaging industry. These molds are designed to meet the growing demand for innovative bottle designs and superior quality packaging.The company, which has been in the business for over 20 years, has established itself as a pioneer in the field of blow bottle mold manufacturing. Its state-of-the-art facility is equipped with the latest technology and a team of highly skilled engineers and technicians who are dedicated to producing top-of-the-line molds that exceed industry standards.The new line of blow bottle molds is the result of extensive research and development, and the company has taken great care to ensure that each mold is engineered to perfection. These molds are capable of producing a wide range of bottle designs, from sleek and modern to classic and elegant, catering to the diverse needs of the packaging industry.One of the key features of the new blow bottle molds is their versatility. They are designed to accommodate different types of materials, including PET, HDPE, and PP, allowing manufacturers to produce bottles for various applications, such as beverages, cosmetics, and household products. This flexibility gives businesses the freedom to explore new packaging options and stay ahead of the competition.In addition to their versatility, the new blow bottle molds are also known for their durability and efficiency. They are built to withstand high-speed production processes, ensuring consistent and reliable performance. This not only improves productivity for manufacturers but also reduces downtime and maintenance costs.Furthermore, China Blow Bottle Mold has implemented strict quality control measures to guarantee that each mold meets the highest standards. They undergo rigorous testing to ensure that they can withstand the rigors of the production process and consistently produce high-quality bottles.The company's commitment to innovation and excellence has earned it a reputation for delivering superior products and exceptional customer service. Its team of experts works closely with clients to understand their specific requirements and provide tailored solutions that meet their needs.With the launch of the new line of blow bottle molds, China Blow Bottle Mold is poised to further solidify its position as a leader in the industry. These molds are expected to set new benchmarks for quality and performance, offering manufacturers a competitive edge in the market.The company is confident that its new line of blow bottle molds will be well-received by the industry and anticipates strong demand from both existing and new clients. It is committed to continuing its tradition of excellence and looks forward to playing a pivotal role in shaping the future of packaging.In conclusion, China Blow Bottle Mold's new line of blow bottle molds is a testament to its unwavering dedication to innovation and quality. These molds are set to redefine the standards for bottle packaging, offering manufacturers a reliable and versatile solution that meets the demands of today's market. With its track record of success and commitment to customer satisfaction, the company is well-positioned to lead the way in the industry for years to come.

Innovative Blow Molding Machine Offers Revolutionary Technology in Manufacturing

Apollo Blow Molding Machine, a leading manufacturer in the blow molding industry, has been making waves with its innovative technology and commitment to providing high-quality products for its customers. With a focus on delivering efficient and reliable solutions for a wide range of blow molding applications, the company has established itself as a trusted partner for businesses around the world.The Apollo Blow Molding Machine is known for its precision engineering and advanced features, which allow for seamless production processes and superior product quality. From creating custom molds to delivering fully integrated blow molding systems, Apollo offers a comprehensive range of services to meet the diverse needs of its customers.One of the key strengths of Apollo Blow Molding Machine is its ability to tailor its products and services to the specific requirements of each client. The company takes pride in its collaborative approach to working with customers, ensuring that they receive the most effective solutions for their blow molding needs. Whether it's designing a new production line or optimizing an existing system, Apollo's team of experts is dedicated to delivering results that exceed expectations.In addition to its commitment to meeting customer needs, Apollo Blow Molding Machine also prioritizes sustainability and environmental responsibility in its operations. The company continuously seeks to develop new technologies and processes that minimize waste and energy consumption, contributing to a greener, more sustainable future for the industry as a whole.With a global presence and a strong reputation for quality and reliability, Apollo Blow Molding Machine has earned the trust of numerous clients across a wide range of industries. Whether it's manufacturing packaging for consumer goods, automotive components, or industrial containers, Apollo's solutions have proven to be a valuable asset for businesses seeking to optimize their production processes.Moreover, Apollo Blow Molding Machine's dedication to continuous innovation and improvement has kept the company at the forefront of the industry. By investing in research and development, as well as staying ahead of the latest technological advancements, Apollo ensures that its products and services remain competitive and relevant in a rapidly evolving market.The success of Apollo Blow Molding Machine can be attributed not only to its cutting-edge technology and customer-centric approach, but also to the dedication and expertise of its team. The company's employees are highly skilled and experienced professionals who are passionate about delivering exceptional results for their clients. Their commitment to excellence and their ability to adapt to the ever-changing demands of the industry have been instrumental in driving Apollo's success.Looking to the future, Apollo Blow Molding Machine remains committed to upholding its values of quality, innovation, and customer satisfaction. The company is poised to continue its growth and expand its reach, while staying true to its core principles. With a solid foundation built on expertise, integrity, and forward thinking, Apollo is well positioned to lead the way in the blow molding industry for years to come.In conclusion, Apollo Blow Molding Machine has established itself as a leader in the industry, with a strong reputation for delivering exceptional products and services. Through its focus on customer collaboration, sustainability, innovation, and a talented team, the company has solidified its position as a trusted partner for businesses around the world. As it continues to grow and evolve, Apollo's commitment to excellence and its dedication to meeting the needs of its clients will undoubtedly drive its ongoing success.

SEO Title: "The Evolution of Plastic Blowing Mold: A Comprehensive Overview

Plastic Blowing Mold - Revolutionizing the Manufacturing IndustryPlastic blowing mold is a process that has been used in the manufacturing industry for years. It involves the use of a variety of machines and tools to create products that are made of plastic. From water bottles to toys and automotive components, the plastic blowing mold process has played an essential role in the creation of many everyday products that we use today.One company that has made significant contributions to the plastic blowing mold industry is a leading manufacturer whose brand name needs to be removed. This company has revolutionized the manufacturing process with its wide range of high-quality products, including blow molding machines, molds, and other auxiliary equipment.The company has been in the plastic blowing mold industry for over two decades and has established a reputation for offering innovative solutions in the market. Boasting a team of engineers and technicians with a vast understanding of the industry, the company has created state-of-the-art designs, which have helped to reduce production costs while optimizing efficiency.One of the secret ingredients that the company has relied on to stay ahead of the competition is its dedication to research and development. They have invested heavily in developing new technologies and designs that help to improve the production process, produce high-quality products with precise specifications, and enhance the longevity of the machines.The company offers a wide range of plastic blowing mold products, including:1. Blow molding machines - These machines are designed to help companies produce a wide variety of hollow plastic products, including water bottles, cosmetic containers, containers for household and industrial chemicals, and automotive components.2. Molds - The company has also created an impressive range of molds that are customized to meet specific customer requirements. The molds are designed to help clients achieve accuracy, speed, and consistency in their production process.3. Auxiliary equipment - The company also provides a broad range of auxiliary equipment, including coolers, dryers, grinders, and conveyors. These devices support the production process and help to optimize the performance of the machines.The company's mission is to provide the best plastic blowing mold solutions while ensuring that the highest quality standards are met. The company's engineers use sophisticated software to design and test molds and machines, ensuring that they offer the best solutions for its clients.Moreover, the company has an in-house quality control department whose primary responsibility is to conduct quality checks and ensure that products meet the specifications before they are shipped to clients. Each product undergoes a series of rigorous inspection procedures, which include dimensional testing, leak testing, and visual examinations, among others. This ensures that the products are of the highest quality standards.Besides guaranteeing top-quality products, the company has also embraced advanced communication systems that ensure that clients' needs are met promptly. Customers can access the company's representatives via phone, email, and social media.In conclusion, the efforts and expertise that the {need remove brand name} has employed in developing the plastic blowing mold industry have revolutionized the manufacturing process. They offer a wide range of high-quality products and auxiliary equipment that have helped many clients in various industries save on cost and time while ensuring that quality standards are met. For businesses looking to make the most out of their production process, the products and services provided by this company are worth investing in.