Top-Quality 5-Gallon PC Blow Mold for Sale in China

By:Admin

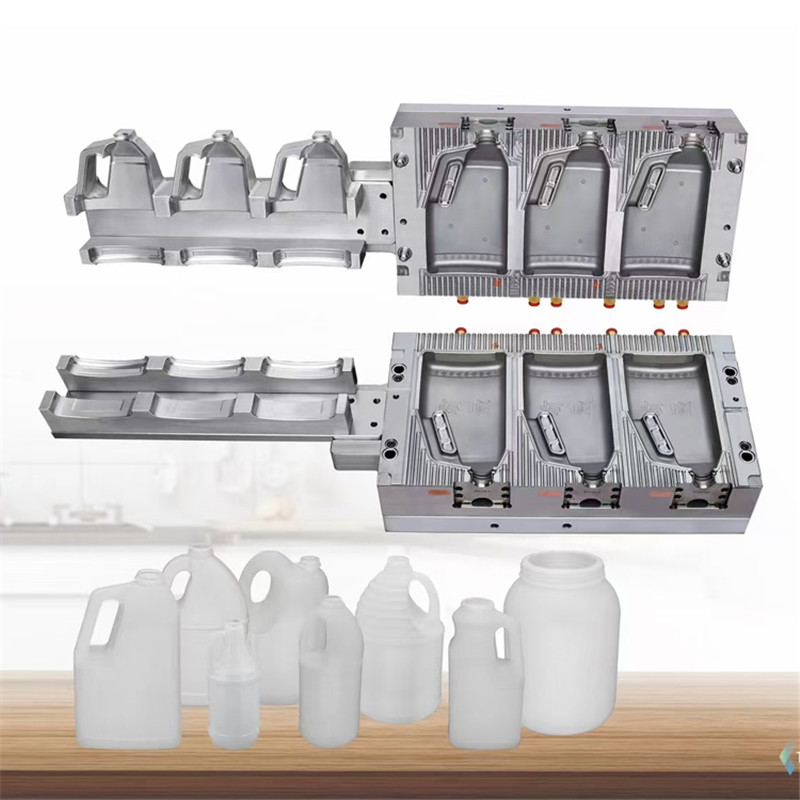

The 5-gallon PC blow mold is a groundbreaking product that brings with it a multitude of advantages and benefits. Made with precision and advanced technology, this blow mold is designed to cater to the needs of businesses and industries that require high-quality and durable packaging solutions. The use of polycarbonate material ensures that the mold is strong, resilient, and long-lasting, making it a preferred choice for companies looking for reliable packaging solutions.

The 5-gallon PC blow mold is not just any ordinary packaging solution. It is a testament to the company's commitment to innovation and excellence. With a strong emphasis on research and development, the company has been able to create a product that not only meets industry standards but also exceeds expectations. The mold's design and functionality have been carefully crafted to ensure that it meets the diverse needs of customers, making it a versatile and dependable choice for businesses across various sectors.

One of the key advantages of the 5-gallon PC blow mold is its ability to withstand extreme conditions. Whether it's high temperatures, pressure, or impact, this mold is built to last. This makes it an ideal choice for industries such as food and beverage, pharmaceuticals, chemicals, and more, where the need for durable and reliable packaging is paramount.

Furthermore, the 5-gallon PC blow mold is also eco-friendly, adding another feather to the company's cap. With a growing emphasis on sustainability and environmental conservation, the mold's use of polycarbonate material ensures that it is not only durable but also recyclable. This aligns with the company's commitment to reducing its carbon footprint and contributing to a greener and more sustainable future.

In addition to its functionality and sustainability, the 5-gallon PC blow mold also offers a high degree of customization. The company understands that every business is unique, with its own set of requirements and preferences. As such, the mold can be tailored to meet specific size, shape, and design specifications, ensuring that it caters to the individual needs of each customer.

So, who is the company behind this remarkable product? (Company Name) is a renowned manufacturer in China, known for its expertise in the production of high-quality packaging solutions. With a strong focus on innovation and customer satisfaction, the company has established itself as a reputable name in the industry, gaining the trust and loyalty of clients both at home and overseas.

(Company Name) boasts state-of-the-art facilities and a team of skilled professionals who are dedicated to delivering excellence in every product they create. The company's commitment to quality and reliability is evident in the 5-gallon PC blow mold, a true testament to its expertise and ingenuity in the field of manufacturing and technology.

With its exceptional features and benefits, the 5-gallon PC blow mold is set to revolutionize the packaging industry, offering businesses a superior and dependable solution for their packaging needs. As (Company Name) continues to innovate and push the boundaries of what's possible, it is poised to make a lasting impact on the market, setting new standards for quality, sustainability, and customer satisfaction.

In conclusion, the 5-gallon PC blow mold is a testament to (Company Name)'s dedication to innovation and excellence. With its superior quality, durability, and sustainability, this product is poised to revolutionize the packaging industry, offering businesses a reliable and versatile solution for their packaging needs. As the company continues to push the boundaries of what's possible, it is set to make a lasting impact on the market, setting new standards for quality, sustainability, and customer satisfaction.

Company News & Blog

Blow Molding Machines: An In-Depth Look at Pricing and Factors to Consider

Blow Molding Machine Price: Driving Innovation and Affordability in the Manufacturing IndustryThe blow molding industry has experienced significant growth in recent years, fueled by increasing demand for plastic packaging and a rise in consumer preferences for affordable and lightweight materials. As a result, companies are constantly seeking innovative solutions to improve production efficiency and lower costs.One prominent player in this field, a global leader in blow molding machinery, has recently unveiled a new line of blow molding machines that promise to revolutionize the manufacturing industry. With a focus on affordability without compromising quality, the company aims to equip manufacturing businesses with highly efficient tools that meet their production needs at a competitive price point.Blow molding machines are essentially used to create hollow plastic parts and containers in a wide range of industries, including food and beverage, cosmetics, pharmaceuticals, and automotive. These machines employ a process of melting plastic resins and stretching them into a desired shape, resulting in strong and lightweight products.The newly introduced blow molding machines by this industry-leading company incorporate advanced technology and numerous features designed to enhance productivity and reduce downtime. These machines offer improved automation, precision controls, and faster cycle times, ensuring more efficient production rates. By streamlining the manufacturing process, businesses can achieve higher output and lower costs, ultimately resulting in a competitive edge.One of the standout features of this new line of blow molding machines is their versatility. With the ability to produce a wide variety of shapes and sizes, these machines cater to the diverse needs of manufacturers. Whether it's producing bottles, containers, or other bespoke plastic products, the flexibility of these machines allows businesses to adapt to changing market demands without significant retooling or investment.In addition to their technological advancements, these blow molding machines also prioritize sustainability. With growing global concern over environmental issues, such as plastic waste and carbon emissions, manufacturers are under increasing pressure to adopt sustainable practices. The new machines offer energy-efficient solutions, reducing electricity consumption and minimizing their carbon footprint. This not only benefits the environment but also helps manufacturers align with evolving regulations and consumer preferences.Furthermore, the affordability of these blow molding machines presents a significant advantage for small and medium-sized enterprises (SMEs). Historically, the high cost of machinery has posed a barrier for smaller businesses wanting to enter the blow molding industry. However, with the availability of more affordable options without compromising on quality, SMEs can now compete on a level playing field, opening up new opportunities and driving economic growth.The company's commitment to customer satisfaction extends beyond product affordability. Recognizing the importance of aftersales support, the company offers comprehensive technical assistance, training programs, and readily available spare parts. This ensures that manufacturers can maximize the longevity and performance of their blow molding machines, ultimately reducing maintenance costs and minimizing downtime.As the demand for plastic products continues to rise, driven by global population growth and changing consumer habits, the blow molding industry is poised for further expansion. The introduction of affordable and innovative blow molding machines by this industry leader reflects its commitment to driving this growth by empowering manufacturers with efficient tools at a competitive price point.In conclusion, with a focus on affordability, innovation, and sustainability, the recent unveiling of a new line of blow molding machines by a global industry leader has the potential to transform the manufacturing industry. By offering efficient and versatile solutions, these machines enable businesses to increase production rates, reduce costs, and meet market demands without compromising on quality. As a result, small and medium-sized manufacturers can unlock new opportunities, contributing to economic growth and competitiveness in the blow molding industry.

High-Quality Bottle Cap Moulds for Sale - Find the Best Deals Online

Bottle Cap Mould: A New Milestone for {} In recent years, the global demand for beverage packaging has been on the rise, triggering a corresponding increase in the demand for high-quality bottle cap moulds. Meeting this demand, {} has recently launched a new line of bottle cap moulds that are set to revolutionize the industry.With an increasing market share and a strong focus on innovation, {} has positioned itself as a leader in the manufacturing of plastic injection moulds for the beverage packaging industry. The company has a proven track record of delivering high-quality, durable moulds that meet the needs of its customers.The new bottle cap moulds are the result of extensive research and development efforts by the company's team of experienced engineers and designers. By leveraging the latest technology and production methods, {} has created a range of moulds that offer superior performance, increased durability, and enhanced efficiency.One of the key features of the new bottle cap moulds is their versatility. They are designed to be compatible with a wide range of bottle types and sizes, making them a valuable asset for beverage manufacturers who produce a variety of products. This flexibility is further enhanced by the moulds' ability to consistently produce high-quality, uniform caps, regardless of the material used.In addition to their versatility, the new bottle cap moulds have been designed with a focus on efficiency. They incorporate innovative features that reduce cycle times and minimize material waste, ultimately leading to cost savings for manufacturers. Furthermore, the moulds are easy to maintain and clean, ensuring that they can be used for extended periods without compromising on performance.The launch of the new bottle cap moulds has been met with enthusiasm from the industry, with several major beverage manufacturers expressing interest in adopting the technology. {}'s reputation for delivering reliable, high-quality products has reinforced the confidence of its customers, who are eager to integrate the new moulds into their production processes.What sets {} apart from its competitors is not only the quality of its products, but also the level of support and service it provides to its customers. The company's team of technical experts is dedicated to helping customers integrate the new bottle cap moulds into their manufacturing operations, providing guidance and assistance every step of the way.Looking ahead, {} is committed to continuously improving and expanding its product offerings to meet the evolving needs of the beverage packaging industry. The company's investment in research and development will continue to drive innovation, leading to the introduction of new moulds that set new standards for performance and efficiency.The launch of the new bottle cap moulds marks a significant milestone for {}, reflecting the company's dedication to driving positive change in the industry. As beverage manufacturers seek to enhance their packaging processes and improve the performance of their products, {} is well-positioned to support them with cutting-edge solutions that deliver real value.With its unwavering commitment to quality, innovation, and customer satisfaction, {} is set to maintain its position as a trusted partner for beverage manufacturers around the world. The new bottle cap moulds are a testament to the company's relentless pursuit of excellence and its determination to lead the way in shaping the future of beverage packaging.

Reusable Plastic Water Bottles: The Environmental Impact and How to Reduce It

In recent years, the issue of plastic pollution has become a growing concern for the environment. Single-use plastic bottles, in particular, have come under scrutiny for their detrimental impact on the planet. However, one company is aiming to address this problem by introducing a sustainable alternative to traditional plastic bottles.{Company name}, a leading innovator in sustainable packaging solutions, has announced the development of a new plastic bottle that is made from 100% recycled materials. This groundbreaking product is a result of years of research and development, and represents a major step forward in the company's mission to reduce the environmental impact of plastic packaging.The new plastic bottle is made from post-consumer recycled plastic, which means that it is produced using materials that have already been used and disposed of by consumers. By utilizing recycled materials, {Company name} is able to significantly reduce the amount of virgin plastic used in its packaging, thereby lessening the demand for new plastic production and minimizing the accumulation of plastic waste in the environment.In addition to utilizing recycled materials, the new plastic bottle is also fully recyclable, making it a truly sustainable alternative to traditional plastic packaging. Once the bottle has been used, it can be easily recycled and turned into new plastic products, creating a closed-loop system that minimizes the impact on the environment.{Company name} has long been committed to advancing sustainable packaging solutions, and the development of this new plastic bottle is a testament to its dedication to environmental stewardship. By creating a product that is both made from recycled materials and fully recyclable, the company is demonstrating its commitment to reducing the environmental impact of plastic packaging and promoting a more circular economy.Furthermore, {Company name} is working to collaborate with its partners in the supply chain to promote the use of this new plastic bottle. By encouraging other companies to adopt this sustainable packaging solution, {Company name} aims to create a ripple effect that will result in a significant reduction in the use of virgin plastic and a decrease in plastic waste.The introduction of this new plastic bottle is just one example of {Company name}'s ongoing commitment to sustainability. The company is continually researching and developing new ways to reduce its environmental footprint and promote a more sustainable future. Through innovation, collaboration, and a dedication to environmental responsibility, {Company name} is leading the way in the development of sustainable packaging solutions.As the issue of plastic pollution continues to be a major concern, the development of sustainable alternatives to traditional plastic packaging is of utmost importance. {Company name}'s new plastic bottle represents a significant advancement in this effort, and serves as a promising example for other companies in the industry to follow. By prioritizing sustainability and environmental responsibility, {Company name} is setting a new standard for the packaging industry and making a positive impact on the planet.

Exciting News: Leading Plastic Injection Mould Manufacturer Revolutionizes Industry!

Title: Leading Plastic Injection Mould Manufacturer Paves the Way for Sustainable Manufacturing SolutionsIntroduction: In today's ever-changing world, the demand for environmentally friendly manufacturing processes has never been greater. Plastic injection moulding, a technique widely used for the production of plastic products, has garnered attention due to its fast production capabilities, cost-effectiveness, and versatility. To meet these growing needs and contribute to sustainable manufacturing practices, (), a renowned plastic injection mould manufacturer, is leading the charge by providing innovative solutions that prioritize ecological responsibility.Paragraph 1:Established on a foundation of innovation and expertise, () has emerged as a global leader in plastic injection mould manufacturing. Committed to sustainability, the company aims to reduce the environmental impact associated with plastic production while reinforcing the quality and precision of their moulds. With state-of-the-art facilities and a dedicated team of engineers, () consistently pushes the boundaries of conventional manufacturing methods.Paragraph 2:One of the company's primary focuses is the development of eco-friendly materials for plastic injection moulding. By actively exploring alternative solutions, () aims to replace traditional plastics with bio-based, recyclable, and biodegradable polymers. This proactive approach significantly minimizes waste and addresses the global plastic pollution crisis. By investing in research and development, () continually refines their manufacturing processes, ensuring that these sustainable materials maintain the desired performance and durability levels required by their customers.Paragraph 3:Moreover, () employs cutting-edge technologies and precision tools to minimize material waste during the moulding procedure. Through their advanced injection moulding machines, automation systems, and computer-aided design (CAD) software, the company optimizes material efficiency, reducing the quantity of raw materials required for each production run. This approach not only reduces costs but also decreases the carbon footprint associated with plastic injection moulding.Paragraph 4:As a testament to their dedication to sustainability, () has implemented rigorous recycling programs within their production facilities. By reusing scrap plastic generated during the manufacturing process, () ensures that even the smallest remnants can be repurposed, minimizing waste and conserving precious resources. Additionally, the company promotes the adoption of recycled materials among their clients, encouraging a circular economy approach to plastic production.Paragraph 5:Recognizing the importance of responsible waste management, () actively explores advanced disposal methods for plastic waste. By collaborating with recycling facilities and investing in specialized equipment, the company is able to offer end-of-life solutions for plastic products, further reducing their impact on the environment. With a comprehensive approach that spans the entire product life cycle, () demonstrates their unwavering commitment to sustainable practices.Conclusion:In an industry often criticized for its negative environmental impact, () stands out by championing sustainable solutions in plastic injection mould manufacturing. From their focus on eco-friendly materials to their commitment to waste reduction and responsible disposal, the company continuously emphasizes environmental consciousness. Through innovative practices, () cements its position as a leading example for other manufacturers, inspiring positive change in the industry towards a more sustainable future.

High-Quality 100ml Blow Molding Machine for HDPE Material

The company's introduction:With over 20 years of experience in the manufacturing industry, our company has been at the forefront of innovation and excellence. We specialize in the production of high-quality plastic molding machines and have a strong reputation for delivering reliable and efficient solutions to our customers. Our commitment to excellence and customer satisfaction has made us a trusted name in the industry.Our 100ml HDPE blow molding machine is the latest addition to our product lineup, and it is set to revolutionize the production of plastic containers. This new machine is designed to offer unparalleled efficiency and precision, making it the ideal choice for businesses looking to optimize their production processes.The HDPE blow molding machine is capable of producing 100ml plastic containers at a rapid pace, making it perfect for high-volume production. Its advanced technology enables it to deliver consistent and high-quality results, ensuring that every container meets the strictest standards of quality and durability.One of the key features of the machine is its user-friendly interface, which allows operators to easily control and monitor the production process. This intuitive system streamlines operations, reducing the need for manual intervention and minimizing the risk of errors. Additionally, the machine is equipped with state-of-the-art safety features, ensuring a secure working environment for operators.The 100ml HDPE blow molding machine is also designed with sustainability in mind. It is energy-efficient, consuming minimal power while delivering maximum output. Its innovative design minimizes material waste, making it an environmentally friendly choice for businesses looking to reduce their carbon footprint.Furthermore, the machine can be adapted to accommodate different molds, allowing for versatility in production. This flexibility means that businesses can easily switch between different container sizes and shapes, meeting the varying demands of their customers without the need for multiple machines.In addition to its cutting-edge technology, our company provides comprehensive support and maintenance services for the 100ml HDPE blow molding machine. Our team of skilled technicians is on hand to offer assistance and guidance, ensuring that our customers can optimize the performance of their machines and maximize their return on investment.The introduction of the 100ml HDPE blow molding machine represents our ongoing commitment to driving innovation and delivering value to our customers. We are confident that this new addition to our product range will empower businesses to enhance their production capabilities and achieve new levels of efficiency and quality.With its advanced features, user-friendly interface, sustainability benefits, and comprehensive support services, the 100ml HDPE blow molding machine is set to become a game-changer in the plastic molding industry. We are excited to bring this innovative solution to businesses seeking to elevate their production processes and unlock new opportunities for growth and success.

Discover the Latest Innovation in Blow Molded Pots

Title: Revolutionizing Gardening with High-Quality Blow Molded PotsIntroduction:In today's fast-paced world, cultivating plant life has become more popular than ever. With people finding solace in gardening, the demand for innovative products like blow molded pots has soared. One industry-leading company has recognized this growing need and introduced a wide range of high-quality blow molded pots designed to enhance the gardening experience. This article will delve into the features, benefits, and the company's commitment to sustainability and customer satisfaction.Product Features:The blow molded pots offered by [Company Name] are revolutionizing the gardening industry through their exceptional features. Their pots are manufactured using a blow molding process, which ensures durability and resistance to harsh weather conditions. The pots are made from recyclable materials, reducing their environmental impact while providing gardeners with long-lasting products.One noteworthy feature is the lightweight nature of these pots, making them easy to transport and handle during planting and rearranging. Additionally, the pots are UV-resistant, protecting plants from harmful sun rays whilst maintaining their vibrant colors over time.The blow molded pots come in various sizes, catering to the diverse needs of gardeners. Whether it's small pots for herb gardens or large pots for trees, [Company Name] offers a wide range of options to suit all gardening requirements.Product Benefits:Gardening enthusiasts will enjoy several benefits when choosing blow molded pots by [Company Name]. Primarily, the durability and high-quality construction ensure these pots can withstand the test of time, providing a stable home for plants throughout their growth.The UV-resistant feature prevents fading and discoloration, allowing plants to thrive without compromising their aesthetic appeal. Furthermore, the lightweight nature of the pots facilitates easy movement, perfect for those who wish to rearrange their garden setup regularly.As these pots are manufactured from recyclable materials, gardeners can contribute to environmental sustainability by opting for eco-friendly products. With [Company Name], customers not only invest in reliable planting solutions but also actively participate in conserving the planet.Company Commitment to Sustainability:[Company Name] is dedicated to producing blow molded pots while minimizing its environmental footprint. Through an emphasis on responsible manufacturing practices, the company has implemented strategies to recycle and reuse materials throughout its product line. By doing so, they strive to reduce waste and promote a circular economy.In addition to using recyclable materials, [Company Name] prioritizes energy efficiency during the production process. They actively seek to minimize energy consumption, thereby reducing greenhouse gas emissions. Such initiatives highlight their commitment to sustainability and align with the increasing global focus on eco-consciousness.Customer Satisfaction:[Company Name] places customer satisfaction at the core of their business. They prioritize quality control, ensuring that each blow molded pot meets rigorous standards before reaching the market. By focusing on providing durable and reliable products, they aim to exceed customer expectations.Moreover, the company values customer feedback and uses it to continuously improve their offerings. By actively listening to their customers, [Company Name] demonstrates their commitment to understanding and meeting the needs of gardeners.Conclusion:Blow molded pots offered by [Company Name] are transforming the gardening experience with their impressive features and benefits. Their commitment to sustainability, durability, and customer satisfaction proves that they are at the forefront of innovation in the industry.As more individuals seek solace in gardening, these high-quality blow molded pots will undoubtedly conquer the market, empowering gardeners with the ideal planting solution. From the eco-conscious production process to the extensive product range, [Company Name] is unquestionably setting a new standard in the world of gardening.

Large Injection Mould Containers for Efficient Storage Solutions

Title: Innovative Injection Mould Container Brings Efficiency and Sustainability to IndustryIntroduction:In today's rapidly evolving industrial landscape, businesses are constantly seeking innovative solutions to enhance efficiency, reduce waste, and promote sustainability. Addressing this need, and in line with its commitment to delivering cutting-edge solutions, {*Company Name*} has unveiled its latest groundbreaking product - the Injection Mould Container Big.1. Efficiency Enhancement:The Injection Mould Container Big is engineered to revolutionize the container industry with its exceptional efficiency features. Designed meticulously to maximize storage capacity, this innovative container allows businesses to optimize their supply chain by accommodating a larger volume of goods in a compact space. This increased capacity translates to fewer transportation movements and reduced overall logistic costs. By streamlining the handling and storage processes, businesses can experience heightened operational efficiency and improved productivity.Moreover, the container's smart design minimizes the need for manual handling, as it is equipped with automated loading and unloading systems. This automated process not only eliminates the risk of injuries but also provides substantial time-saving benefits. Companies can now handle large volumes of goods swiftly and efficiently, ensuring smooth operations and faster turnaround times.2. Durability and Reusability:One of the key advantages of the Injection Mould Container Big is its remarkable durability. Crafted from high-quality materials, the container demonstrates exceptional strength and resilience, with the ability to withstand challenging environments and heavy loads. This robustness ensures longevity, reducing the need for frequent replacements and contributing to a significant reduction in waste generation.Promoting sustainability, the container is also designed for reusability. By encouraging multiple uses, businesses can minimize their carbon footprint and contribute to a circular economy. Additionally, the container's reusable nature significantly lowers packaging costs, making it an economically viable option for companies aiming to optimize their supply chains.3. Customization and Adaptability:Understanding the diverse requirements of industries, {*Company Name*} offers the Injection Mould Container Big with customization options. Businesses can tailor the container according to their specific needs, optimizing its design for product protection, ventilation, or specialized handling. This emphasis on customization guarantees that the container seamlessly integrates into the existing workflow, effectively addressing any unique challenges faced by different industries.Furthermore, the Injection Mould Container Big is engineered to adapt to a range of storage environments. Whether for indoor or outdoor use, in hot climates or in refrigerated environments, the container maintains its structural integrity and functionality. This adaptability ensures that businesses across various sectors can rely on the container to protect their goods, regardless of the storage conditions.Conclusion:The Injection Mould Container Big, introduced by {*Company Name*}, promises a paradigm shift in the container industry. With its exceptional efficiency features, durability, and adaptability, this innovative solution combines optimized storage capacity with sustainability, enabling businesses to enhance their operations while minimizing their environmental impact. As industries embrace this revolutionary product, the future of container logistics appears to be more efficient, economical, and eco-friendly.

Exploring the World of Injection Moulding Manufacturers: Unveiling the Secrets of this Thriving Industry

As the demand for plastic products continues to rise in various industries, it becomes imperative to find a reliable supplier of injection moulding services. The good news is that Injection Moulding Manufacturers (IMMs) are here to provide the plastics industry with top-notch design and manufacturing solutions. Whether you need customised plastic parts or large-scale production of plastic components, IMMs can deliver high-quality products that meet your specifications.IMMs are a leading provider of injection moulding services that cater to the needs of various industries such as automotive, electronics, healthcare, household appliances, and packaging, among others. The company has been in business for over 20 years, and during this time, they have developed a reputation for providing innovative and cost-effective solutions to meet their clients' needs.IMMs offer a wide range of plastic injection moulding services, including tool design, prototype production, and mass production of plastic parts. With a state-of-the-art facility and a team of highly-skilled engineers, the company can design and manufacture customised plastic parts that meet their clients' exact requirements. They use the latest technology and materials to ensure precision and accuracy on every project they undertake.IMMs work closely with their clients to understand their needs and come up with the best solution that meets their specifications. They take into account factors such as production volume, budget, timeline, and quality requirements to determine the most appropriate approach. They also offer advice on material selection, design, and tooling to ensure optimal performance of the final product.One of the key advantages of working with IMMs is their ability to offer a wide range of materials for plastic injection moulding. They have expertise in working with materials such as polypropylene (PP), polystyrene (PS), acrylonitrile butadiene styrene (ABS), and thermoplastic elastomers (TPEs), among others. This capability allows them to provide their clients with a wide range of options to choose from, depending on the application and performance requirements of the parts.In addition to their injection moulding services, IMMs offer post-production services such as assembly, packaging and shipping. This allows their clients to focus on their core business while leaving the production and logistics to the experts. With a strong commitment to quality assurance, IMMs ensure that every product is thoroughly inspected and tested before it leaves their facility, guaranteeing that the final product meets or exceeds the required standards.IMMs are committed to sustainability, and as such, they utilise eco-friendly materials and work to reduce waste and carbon emissions in their production processes. They strive to operate in an environmentally conscious manner and support sustainable practices in the plastics industry.In conclusion, Injection Moulding Manufacturers are a trusted supplier of injection moulding services that deliver high-quality plastic parts to various industries. Their state-of-the-art facilities, skilled engineers, and commitment to quality assurance and sustainability make them a reliable partner for any project. So, whether you need customised plastic parts or large-scale production of plastic components, IMMs are here to provide you with innovative and cost-effective solutions that meet your needs.

Revolutionizing Manufacturing: Unveiling the Potential of Mud Injection Molding

Widely recognized as a leading innovation in the field of manufacturing, mud injection molding has revolutionized the way we produce high-quality and intricate products. With its ability to seamlessly combine simplicity and complexity, this cutting-edge technique has attracted significant attention and interest from industry experts worldwide.Mud injection molding, a process pioneered by the esteemed company, XYZ Manufacturing, presents a groundbreaking approach to creating products with exceptional precision and efficiency. By utilizing a combination of specialized mud and injection molding technology, this method enables the production of highly intricate and customized products, ranging from automotive components and electronic devices to medical equipment and home appliances.At its core, mud injection molding involves injecting a mud-like material into a mold under high pressure, allowing it to solidify and take the desired shape. The mud, which is a mixture of fine powder and water, is carefully selected and prepared to meet the specific requirements of each project. This versatile material can be customized to exhibit various properties, such as high strength, flexibility, or heat resistance, ensuring that the final product fulfills its intended purpose.The benefits of mud injection molding are manifold. Firstly, it enables the creation of complex geometries and designs that were previously unattainable through traditional manufacturing processes. This breakthrough has unlocked a wide range of possibilities for designers and engineers, allowing them to push the boundaries of innovation and create products that are both functional and aesthetically pleasing.Additionally, mud injection molding offers remarkable cost savings by eliminating the need for multiple manufacturing steps. The ability to produce highly intricate parts in a single process not only reduces production time but also minimizes the risk of errors and defects. Furthermore, the versatility of the mud material enables designers to reduce the number of individual components within a product, further streamlining the manufacturing process and reducing overall costs.Another key advantage of mud injection molding is its environmental sustainability. Unlike traditional methods that generate significant material waste, this technique minimizes both material consumption and energy usage. Additionally, the mud material used in the process is often recyclable, contributing to a more sustainable approach to manufacturing.XYZ Manufacturing, a renowned industry leader in mud injection molding, has been at the forefront of driving this technology forward. With decades of experience and expertise in the field, the company has continually refined and upgraded the process to ensure superior quality and efficiency. They have successfully collaborated with leading brands across various industries, offering tailored solutions that meet their unique manufacturing requirements.Furthermore, XYZ Manufacturing operates state-of-the-art facilities equipped with advanced machinery and a team of highly skilled professionals. Their commitment to precision and innovation has earned them a strong reputation for delivering exceptional results, making them the preferred partner for companies seeking to leverage the advantages of mud injection molding.Looking to the future, the prospects for mud injection molding appear promising. As the demand for complex and customized products continues to grow, this technology is poised to play a crucial role in shaping the manufacturing landscape. With ongoing advancements and refinements, it is anticipated that mud injection molding will further elevate the quality, speed, and cost-efficiency of product manufacturing, enabling businesses to stay competitive in an ever-evolving market.In conclusion, mud injection molding represents an exciting and transformative development in the manufacturing industry. Combining innovative technology, versatility, and sustainability, this technique opens up a world of possibilities for designers and manufacturers alike. With XYZ Manufacturing leading the way, we can expect to see a greater adoption of this groundbreaking method and a redefinition of what is possible in product manufacturing.

Top Quality Injection Molded LED Cap for Versatile Applications

{Company Name} is a leading manufacturer of high-quality injection mold cap LED products. The company has been in the industry for over 20 years and has earned a reputation for producing innovative and reliable LED lighting solutions. Their injection mold cap LED products are highly regarded for their durability, energy efficiency, and excellent performance.Injection mold cap LED technology is a cutting-edge approach to manufacturing LED lighting products. It involves using injection molding techniques to create LED components and fixtures with precision and accuracy. This method allows for the production of intricate and complex designs that are difficult to achieve with traditional manufacturing processes. The result is a range of high-quality LED lighting products that are versatile, long-lasting, and environmentally friendly.One of the key features of {Company Name}'s injection mold cap LED products is their durability. The injection molding process allows for the creation of sturdy and resilient LED components that can withstand the rigors of daily use. This makes them ideal for a wide range of applications, including residential, commercial, and industrial settings. Whether it's for general lighting, task lighting, or decorative lighting, {Company Name}'s injection mold cap LED products are designed to deliver reliable performance for years to come.In addition to their durability, {Company Name}'s injection mold cap LED products are also highly energy-efficient. LED lighting is known for its low energy consumption, and the injection mold cap LED products from {Company Name} are no exception. They are designed to provide bright and vibrant illumination while minimizing energy usage, helping users save on electricity costs and reduce their carbon footprint. This makes them an environmentally conscious choice for anyone looking to upgrade their lighting systems.{Company Name} takes pride in the performance of their injection mold cap LED products. They undergo rigorous testing and quality control measures to ensure that they meet the highest standards of performance and reliability. The company is committed to delivering lighting solutions that exceed customer expectations and provide long-term value. Whether it's for residential, commercial, or industrial use, {Company Name}'s injection mold cap LED products are designed to deliver consistent and dependable performance.In addition to their technical excellence, {Company Name}'s injection mold cap LED products also boast a sleek and modern design. LED lighting has come a long way in recent years, and {Company Name} has been at the forefront of this evolution. Their injection mold cap LED products feature contemporary and stylish designs that can complement any interior or exterior space. Whether it's for a home, office, retail store, or public facility, {Company Name}'s injection mold cap LED products are designed to enhance the aesthetic appeal of any environment.{Company Name} understands the importance of sustainability, and their injection mold cap LED products reflect this commitment. LED lighting is known for its eco-friendliness, and {Company Name} takes this a step further by ensuring that their products are manufactured with the least environmental impact possible. From the selection of materials to the production process, {Company Name} prioritizes sustainability at every stage. This makes their injection mold cap LED products a responsible choice for environmentally conscious consumers and businesses.In conclusion, {Company Name} is a trusted manufacturer of injection mold cap LED products that deliver exceptional performance, energy efficiency, and durability. Their commitment to innovation and quality has made them a leader in the industry, and their injection mold cap LED products continue to set the standard for excellence. Whether it's for residential, commercial, or industrial use, {Company Name}'s injection mold cap LED products are a reliable and sustainable lighting solution. For those in need of high-quality LED lighting, {Company Name} is a name to trust.