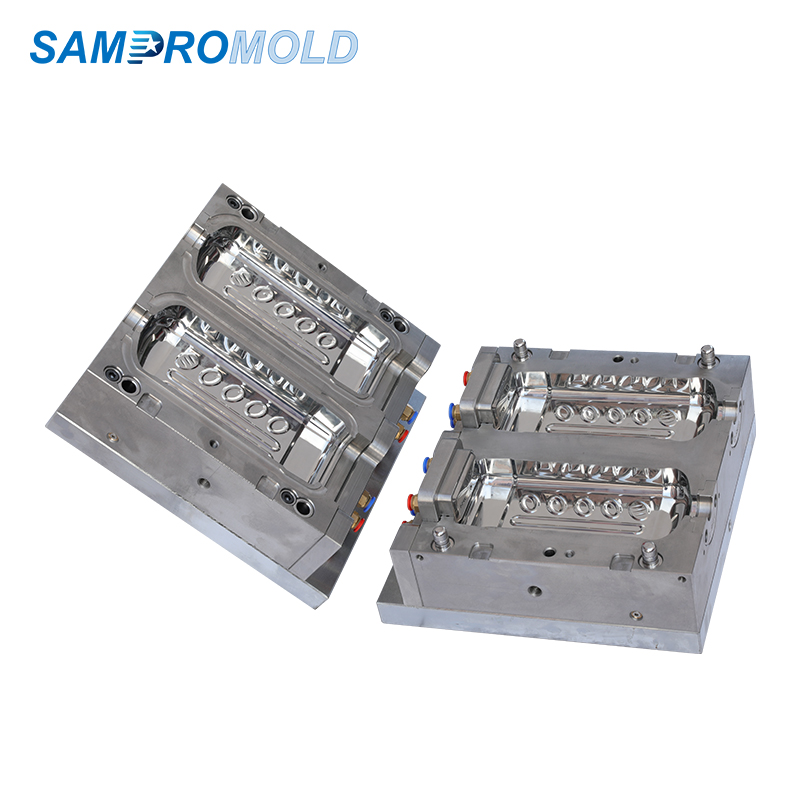

Plastic Injection Mould for Bottle Blow - 3000bph Speed

By:Admin

The new bottle blow mould in plastic injection is a result of years of research and development by the company. With a focus on innovation and technological advancement, the company has consistently been at the forefront of the injection molding industry. Their state-of-the-art production facilities and team of experienced engineers have enabled them to develop cutting-edge solutions for their clients.

The 3000bph bottle blow mould is designed to meet the increasing demand for plastic bottles in the market. With a high-speed production capacity, it offers significant advantages to manufacturers in terms of efficiency and output. The precision and accuracy of the injection molding process ensure that the bottles produced are of high quality and meet industry standards.

One of the key features of the new bottle blow mould is its versatility. It is capable of producing a wide range of bottle sizes and shapes, catering to the diverse needs of different industries. This flexibility allows manufacturers to meet the specific requirements of their customers and stay ahead of their competitors in the market.

In addition to its high production capacity and versatility, the bottle blow mould also offers cost-effective solutions for manufacturers. The efficient use of materials and energy in the injection molding process results in lower production costs, allowing companies to maximize their profits while meeting the growing demand for plastic bottles.

The company's commitment to environmental sustainability is also reflected in the new bottle blow mould. With a focus on reducing waste and energy consumption, the technology is designed to minimize the environmental impact of plastic bottle production. This aligns with the increasing consumer demand for sustainable and eco-friendly packaging solutions.

As a leading player in the injection molding industry, [company name] aims to provide comprehensive support to its clients. With their team of dedicated professionals and after-sales service, they ensure that manufacturers are able to fully optimize the capabilities of the new bottle blow mould. This includes technical support, maintenance services, and training programs to maximize the efficiency and reliability of the technology.

The launch of the 3000bph bottle blow mould in plastic injection marks a significant milestone for the company, further solidifying its position as an industry leader. With its focus on innovation, technological advancement, and customer satisfaction, [company name] continues to set new standards in the injection molding industry.

In conclusion, the new bottle blow mould in plastic injection with a capacity of 3000 bottles per hour is set to revolutionize the production of plastic bottles. With its high-speed production capacity, versatility, cost-effective solutions, and commitment to environmental sustainability, the technology offers significant advantages to manufacturers in various industries. With the support and expertise of [company name], manufacturers can fully optimize the capabilities of the new bottle blow mould and stay ahead of their competitors in the market.

Company News & Blog

150 Litre Blow Molded Pots: A Game-Changer in Gardening Solutions

Blow Molded 150 Litre Pots Revolutionize the Gardening Industry[Company Name], a leader in innovative gardening solutions, has recently introduced their latest product, the Blow Molded 150 Litre Pots. These revolutionary pots are set to transform the gardening landscape by providing growers with a durable and efficient solution to cultivate their plants.With a focus on sustainability and meeting the demands of modern gardening enthusiasts, [Company Name] has developed these blow molded pots to cater to the needs of both amateur and professional growers alike. The pots boast a large capacity of 150 liters, providing ample space for plants to grow and thrive.One of the key features that sets the Blow Molded 150 Litre Pots apart is their construction. Manufactured using state-of-the-art blow molding technology, these pots are made from high-quality, durable materials that will withstand the test of time. The blow molding process ensures uniform thickness, making the pots resistant to cracking, chipping, and breaking.Furthermore, the Blow Molded 150 Litre Pots are designed with reinforced rims and sturdy handles, allowing for easy maneuverability even when filled with soil and fully grown plants. This user-friendly design makes it convenient for gardeners to move their plants as needed, whether for optimizing sunlight exposure or reorganizing their garden layout.In addition to their excellent durability and functionality, these pots also prioritize plant health and growth. The Blow Molded 150 Litre Pots feature a unique drainage system that ensures proper water distribution, preventing waterlogging and root rot. The pots also have ample breathing holes to promote healthy root development and airflow, creating an optimal growing environment for plants.The large capacity of the Blow Molded 150 Litre Pots makes them ideal for growing a variety of plants, including trees, shrubs, and fruits. Whether used in small home gardens or large-scale horticultural operations, these pots offer growers the versatility they need to cultivate a wide range of plant species.Furthermore, [Company Name] is committed to environmental sustainability. The Blow Molded 150 Litre Pots are made from recycled materials, reducing waste and carbon footprint. By choosing these pots, gardeners can actively contribute to the preservation of the environment while enjoying the benefits of an efficient and long-lasting gardening solution.According to [Company Name]'s spokesperson, "We are thrilled to introduce the Blow Molded 150 Litre Pots to the market. This product represents our dedication to providing innovative solutions that meet the needs of gardening enthusiasts while prioritizing sustainability. We believe these pots will greatly enhance the gardening experience for both professionals and amateurs alike."The Blow Molded 150 Litre Pots are now available for purchase on [Company Name]'s website and selected gardening retailers. As the gardening industry continues to evolve, [Company Name] remains at the forefront, ensuring that growers have access to innovative and sustainable solutions that drive their passion for gardening forward.

Unlocking the Secrets to Superior Blow Moulding Techniques

Blow Moulding Super – Leading the Way in Sustainable Packaging SolutionsBlow Moulding Super (BMS), a leading provider of blow moulding solutions, has been pioneering sustainable packaging solutions since its inception. With a focus on innovation and continuous improvement, the company is committed to reducing its environmental footprint while offering cost-effective and high-quality packaging solutions to its customers.Founded in 1997, BMS has grown from a small regional provider to a worldwide network of companies with a presence in over 30 countries. The company’s success is built on its robust engineering expertise, coupled with its unwavering commitment to customer satisfaction. With state-of-the-art manufacturing facilities and a team of highly skilled professionals, BMS is capable of producing customised packaging solutions that meet the unique needs of its clients.BMS’s sustainable approach to packaging is based on three key pillars: reducing material use, maximising reusability, and optimising recyclability. By using less material in its manufacturing process, the company reduces its energy consumption and carbon footprint. BMS also prioritises reusability and recycling, ensuring that its products are designed with a circular economy in mind. These principles have allowed BMS to develop a range of sustainable packaging solutions that meet the highest environmental standards.One of BMS’s flagship products is its line of mono-material packaging solutions. These packages are used in a wide range of industries, from food and beverage to cosmetics and personal care. Mono-material packaging is made from a single material, which simplifies the recycling process and reduces waste. BMS’s mono-material packaging solutions are available in a variety of shapes and sizes, and can be customised to meet the specific needs of each client.BMS also offers a range of other sustainable packaging solutions, including lightweight bottles and containers made from recycled materials. These products are designed to reduce the amount of material used while maintaining the necessary levels of protection and durability. BMS’s lightweight bottles and containers are suitable for a range of applications, including beverage, household and personal care products.In addition to its focus on sustainability, BMS is also committed to delivering exceptional customer service. The company’s sales and customer service teams work closely with clients to understand their unique needs and develop customised packaging solutions that meet those needs. BMS’s engineering team is also available to provide technical support and product development services, ensuring that its clients receive the highest quality products and services.BMS’s commitment to sustainability has been recognised by a number of industry groups and organisations. In 2019, the company was awarded the prestigious Greener Package Award for its sustainable packaging solutions. This award recognises companies that demonstrate a commitment to sustainable packaging and have made significant contributions to reducing their environmental impact.The future of packaging is in sustainability, and BMS is at the forefront of this market trend. With its focus on innovation, high-quality products, and exceptional customer service, the company is well-positioned to continue leading the way in sustainable packaging solutions for years to come.

Discover the Latest Innovation in Plastic Bottle Blow Mould Technology

Title: Innovations in Plastic Bottle Blow Mould Technology: Enhancing Efficiency and Sustainability in PackagingIntroduction:Plastic bottles have become an essential part of our daily lives, serving as a convenient and often necessary means for packaging various products. In recent years, the market demand for plastic bottles has been growing exponentially, leading to increased focus on enhancing their production efficiency and sustainability. Invested in fulfilling these demands, a leading manufacturer in plastic bottle blow mould technology has developed a groundbreaking solution that not only enhances manufacturing efficiency but also contributes to environmental sustainability.Company Overview (remove brand name):{The company}—a pioneer in plastic bottle blow mould technology—has been a leading name in the industry for several decades. With a strong commitment to continuous innovation and cutting-edge research, the company has consistently delivered high-quality products and solutions that meet the evolving needs of diverse sectors. Known for its expertise in mould design and manufacturing, {the company} has earned a reputation for reliability, efficiency, and environmental consciousness.Innovative Plastic Bottle Blow Mould Technology:{The company} has recently unveiled its latest breakthrough in plastic bottle blow mould technology, which promises to revolutionize the packaging industry. The innovative solution encompasses several key features that address the growing demands for efficiency, durability, and sustainability.1. Enhanced Productivity:The newly developed blow mould technology incorporates advanced automation and precision engineering to streamline the manufacturing process. By optimizing the bottle extrusion and stretching process, {the company} has achieved significantly higher production rates, allowing manufacturers to produce more bottles within a specific timeframe. This increased productivity not only improves efficiency for businesses but also contributes to meeting the rising consumer demand efficiently.2. Resource Optimization:Recognizing the need for sustainable practices, {the company} has emphasized resource optimization in its new blow mould technology. By utilizing cutting-edge design techniques, the mould ensures minimum material waste during the production process. This reduces the overall carbon footprint associated with plastic bottle manufacturing. Additionally, the innovative design allows for the use of recycled plastic materials, thus promoting circular economy principles and reducing the reliance on virgin plastics.3. Enhanced Bottle Performance:The newly developed blow mould technology by {the company} focuses on improving bottle durability and performance. Through innovative design and precise control of wall thickness, the mould ensures uniform distribution of material, resulting in stronger and more robust bottles. This not only reduces the chances of deformation during transportation and storage but also enhances the overall user experience. With enhanced packaging integrity, businesses can confidently maintain product quality and reduce the risk of leaks or damages.4. Customization and Product Versatility:{The company}'s blow mould technology enables enhanced customization options for plastic bottle manufacturing. The flexible mould design facilitates the production of bottles in various shapes, sizes, and designs, catering to the diverse requirements of different industries. Whether it is cosmetics, beverages, or household chemicals, businesses can now provide unique and eye-catching packaging solutions to stand out in a competitive market.Conclusion:As the demand for plastic bottles continues to rise across industries, improving efficiency and sustainability in their production becomes imperative. {The company}'s innovative plastic bottle blow mould technology offers a significant breakthrough in addressing these challenges. By combining enhanced productivity, resource optimization, improved bottle performance, and customization options, {the company} is poised to revolutionize the packaging industry, allowing manufacturers to meet consumer demands while minimizing environmental impact. With their commitment to continuous innovation, {the company} sets a strong example for the industry, emphasizing the importance of sustainable solutions in shaping a greener future.

Highly Efficient 2 Layer Tank Blow Molding Machine for Enhanced Manufacturing

2 Layer Tank Blow Molding Machine Revolutionizes Production ProcessThe manufacturing industry has seen a wave of innovation in recent years, with advancements in technology continually shaping the way products are created. One such innovation is the 2 Layer Tank Blow Molding Machine, which has been gaining attention for its ability to revolutionize the production process for various industries.The 2 Layer Tank Blow Molding Machine, developed by a leading machinery company, is designed to meet the growing demand for high-quality, efficient, and cost-effective plastic tanks. The machine's cutting-edge technology allows for the production of tanks with two layers, offering improved strength, durability, and insulation properties.With a growing focus on sustainability and environmental responsibility, the 2 Layer Tank Blow Molding Machine is also equipped to produce tanks using recycled materials, further reducing the environmental impact of production processes. This feature has made the machine an attractive option for companies looking to enhance their green credentials while maintaining high standards of quality and performance.In addition to its innovative technology, the 2 Layer Tank Blow Molding Machine is known for its user-friendly interface and intuitive operation. This allows for seamless integration into existing production lines, minimizing downtime and maximizing efficiency.The machine's versatility and adaptability have made it a popular choice for a wide range of industries, including automotive, chemical, pharmaceutical, and agricultural sectors. Its ability to produce tanks in various sizes and shapes, with customizable features such as in-mold labeling and color options, has further expanded its appeal across different market segments.In a recent statement, the company behind the 2 Layer Tank Blow Molding Machine emphasized the importance of continuous innovation in meeting the evolving needs of the market. They highlighted their commitment to staying at the forefront of technological advancements, ensuring that their machines provide practical solutions for manufacturers looking to streamline their production processes and stay ahead of the competition."We are proud to have developed a machine that addresses the key challenges faced by manufacturers in the production of plastic tanks," said a spokesperson for the company. "Our 2 Layer Tank Blow Molding Machine is a testament to our dedication to innovation and our relentless pursuit of excellence. We believe it will have a significant impact on the industry and help our customers achieve new levels of efficiency and sustainability."The company's track record and expertise in the field of machinery manufacturing have further instilled confidence in the market regarding the capabilities and reliability of the 2 Layer Tank Blow Molding Machine. Their commitment to providing comprehensive support and maintenance services has also been well-received by customers, offering them peace of mind as they integrate the new technology into their operations.The introduction of the 2 Layer Tank Blow Molding Machine has undoubtedly raised the bar for the production of plastic tanks, setting a new standard for quality, efficiency, and sustainability. As industries continue to evolve and adapt to changing market dynamics, innovative solutions like this will play a crucial role in shaping the future of manufacturing. With its advanced technology and practical benefits, the machine is poised to make a lasting impact on the industry and drive positive change in the way products are made.

SEO Title: "The Evolution of Plastic Blowing Mold: A Comprehensive Overview

Plastic Blowing Mold - Revolutionizing the Manufacturing IndustryPlastic blowing mold is a process that has been used in the manufacturing industry for years. It involves the use of a variety of machines and tools to create products that are made of plastic. From water bottles to toys and automotive components, the plastic blowing mold process has played an essential role in the creation of many everyday products that we use today.One company that has made significant contributions to the plastic blowing mold industry is a leading manufacturer whose brand name needs to be removed. This company has revolutionized the manufacturing process with its wide range of high-quality products, including blow molding machines, molds, and other auxiliary equipment.The company has been in the plastic blowing mold industry for over two decades and has established a reputation for offering innovative solutions in the market. Boasting a team of engineers and technicians with a vast understanding of the industry, the company has created state-of-the-art designs, which have helped to reduce production costs while optimizing efficiency.One of the secret ingredients that the company has relied on to stay ahead of the competition is its dedication to research and development. They have invested heavily in developing new technologies and designs that help to improve the production process, produce high-quality products with precise specifications, and enhance the longevity of the machines.The company offers a wide range of plastic blowing mold products, including:1. Blow molding machines - These machines are designed to help companies produce a wide variety of hollow plastic products, including water bottles, cosmetic containers, containers for household and industrial chemicals, and automotive components.2. Molds - The company has also created an impressive range of molds that are customized to meet specific customer requirements. The molds are designed to help clients achieve accuracy, speed, and consistency in their production process.3. Auxiliary equipment - The company also provides a broad range of auxiliary equipment, including coolers, dryers, grinders, and conveyors. These devices support the production process and help to optimize the performance of the machines.The company's mission is to provide the best plastic blowing mold solutions while ensuring that the highest quality standards are met. The company's engineers use sophisticated software to design and test molds and machines, ensuring that they offer the best solutions for its clients.Moreover, the company has an in-house quality control department whose primary responsibility is to conduct quality checks and ensure that products meet the specifications before they are shipped to clients. Each product undergoes a series of rigorous inspection procedures, which include dimensional testing, leak testing, and visual examinations, among others. This ensures that the products are of the highest quality standards.Besides guaranteeing top-quality products, the company has also embraced advanced communication systems that ensure that clients' needs are met promptly. Customers can access the company's representatives via phone, email, and social media.In conclusion, the efforts and expertise that the {need remove brand name} has employed in developing the plastic blowing mold industry have revolutionized the manufacturing process. They offer a wide range of high-quality products and auxiliary equipment that have helped many clients in various industries save on cost and time while ensuring that quality standards are met. For businesses looking to make the most out of their production process, the products and services provided by this company are worth investing in.

Reusable Plastic Water Bottles: The Environmental Impact and How to Reduce It

In recent years, the issue of plastic pollution has become a growing concern for the environment. Single-use plastic bottles, in particular, have come under scrutiny for their detrimental impact on the planet. However, one company is aiming to address this problem by introducing a sustainable alternative to traditional plastic bottles.{Company name}, a leading innovator in sustainable packaging solutions, has announced the development of a new plastic bottle that is made from 100% recycled materials. This groundbreaking product is a result of years of research and development, and represents a major step forward in the company's mission to reduce the environmental impact of plastic packaging.The new plastic bottle is made from post-consumer recycled plastic, which means that it is produced using materials that have already been used and disposed of by consumers. By utilizing recycled materials, {Company name} is able to significantly reduce the amount of virgin plastic used in its packaging, thereby lessening the demand for new plastic production and minimizing the accumulation of plastic waste in the environment.In addition to utilizing recycled materials, the new plastic bottle is also fully recyclable, making it a truly sustainable alternative to traditional plastic packaging. Once the bottle has been used, it can be easily recycled and turned into new plastic products, creating a closed-loop system that minimizes the impact on the environment.{Company name} has long been committed to advancing sustainable packaging solutions, and the development of this new plastic bottle is a testament to its dedication to environmental stewardship. By creating a product that is both made from recycled materials and fully recyclable, the company is demonstrating its commitment to reducing the environmental impact of plastic packaging and promoting a more circular economy.Furthermore, {Company name} is working to collaborate with its partners in the supply chain to promote the use of this new plastic bottle. By encouraging other companies to adopt this sustainable packaging solution, {Company name} aims to create a ripple effect that will result in a significant reduction in the use of virgin plastic and a decrease in plastic waste.The introduction of this new plastic bottle is just one example of {Company name}'s ongoing commitment to sustainability. The company is continually researching and developing new ways to reduce its environmental footprint and promote a more sustainable future. Through innovation, collaboration, and a dedication to environmental responsibility, {Company name} is leading the way in the development of sustainable packaging solutions.As the issue of plastic pollution continues to be a major concern, the development of sustainable alternatives to traditional plastic packaging is of utmost importance. {Company name}'s new plastic bottle represents a significant advancement in this effort, and serves as a promising example for other companies in the industry to follow. By prioritizing sustainability and environmental responsibility, {Company name} is setting a new standard for the packaging industry and making a positive impact on the planet.

High-Quality Stretch Blow Molding Machine for Efficient Production

The global packaging industry is continuously evolving, with a growing emphasis on sustainability, efficiency, and innovation. As a result, companies are investing in advanced equipment and technologies to meet the ever-changing demands of consumers and the market.One such company at the forefront of this transformation is {}. With years of experience and a strong reputation in the packaging industry, they have recently announced the acquisition of state-of-the-art Stretch Blow Molding Machine, signaling their commitment to staying ahead of the curve and providing their customers with the best possible solutions.The Stretch Blow Molding Machine is a key addition to their production line, allowing them to enhance their capabilities in creating high-quality PET bottles and containers. This advanced equipment is designed to meet the growing demand for sustainable and eco-friendly packaging solutions, as it enables the production of lightweight and recyclable containers that are in line with the latest industry trends.The machine boasts advanced features such as precision control systems, high-speed operation, and energy-efficient performance, making it an ideal choice for companies looking to improve their production processes while reducing their environmental impact. Its innovative design and versatile functionality also allow for a wide range of customization options, empowering {} to cater to diverse customer needs and preferences.In addition to its technical capabilities, the Stretch Blow Molding Machine is also aligned with the company's dedication to quality and reliability. Its robust construction and advanced components ensure long-term durability and consistent performance, contributing to the overall efficiency and productivity of their operations.With this latest investment, {} has further strengthened its position as a leader in the packaging industry. By leveraging the capabilities of the Stretch Blow Molding Machine, they are poised to expand their product offerings, enhance their production efficiency, and elevate the overall quality of their packaging solutions.As a company committed to innovation and sustainability, {} recognizes the importance of investing in cutting-edge technologies that align with their values and business objectives. The acquisition of the Stretch Blow Molding Machine reflects their dedication to staying ahead of industry trends, meeting customer demands, and contributing to a more sustainable future.In line with this commitment, {} continues to explore opportunities for growth and improvement, leveraging their expertise and resources to provide innovative packaging solutions that make a positive impact on the market and the environment. By integrating advanced equipment like the Stretch Blow Molding Machine into their operations, they are well-positioned to drive positive change and set new industry standards.Looking ahead, {} is excited about the possibilities that the Stretch Blow Molding Machine presents. They are eager to leverage its capabilities to create innovative packaging solutions that resonate with consumers and meet the evolving needs of the market. With their proven track record and a relentless pursuit of excellence, they are well-equipped to harness the full potential of this advanced equipment and continue their legacy of leadership in the packaging industry.

Second-Hand Pet Blowing Machine: A Cost-Effective Solution for Production Needs

Title: Exploring the Advantages of Second-Hand PET Blowing Machines in the Packaging IndustryIntroduction:The packaging industry plays a crucial role in various sectors, ranging from food and beverages to pharmaceuticals. PET (Polyethylene Terephthalate) bottles have become a staple in this industry due to their lightweight nature, durability, and versatility. To meet the increasing demand for PET bottles, manufacturers often employ innovative PET blowing machines. This article aims to shed light on the benefits of second-hand PET blowing machines, emphasizing cost-effectiveness, sustainability, and reliability.Cost-Effectiveness:With the rising costs of new machinery, many companies are turning to second-hand options to optimize their production processes while minimizing expenses. Second-hand PET blowing machines offer significant cost advantages, allowing companies to allocate their budgets more efficiently. By acquiring high-quality used blowing machines, businesses can save substantial capital, which can then be utilized for other essential investments such as research and development or marketing strategies.Environmental Sustainability:In recent years, environmental consciousness has become a top priority for companies across various industries. By opting for second-hand PET blowing machines, businesses can contribute to environmental sustainability. The carbon footprint associated with manufacturing new machines, including raw material extraction, production, and transportation, can be significantly reduced when reusing existing equipment. Moreover, investing in used machines promotes the concept of circular economy, minimizing waste and conserving resources.Reliability and Performance:While some may presume that second-hand machinery may lack quality or reliability, this is not necessarily the case. Reputed companies often refurbish used PET blowing machines, ensuring they meet industry standards and perform optimally. These machines undergo thorough inspection, repairs, and testing before being offered for resale. This meticulous process guarantees that customers receive equipment that functions as efficiently as new machines.Reduced Downtime and Production Losses:Companies in the packaging industry are constantly seeking ways to minimize production downtime and losses. When purchasing a new PET blowing machine, it often entails a waiting period for manufacturing, delivery, and installation. In contrast, second-hand machines can be readily available, significantly reducing downtime and allowing businesses to quickly resume their production. Moreover, since these machines are refurbished by experts, the risks of breakdowns or performance issues are minimized, further reducing potential production losses.Technical Support and Warranty Options:One concern while buying second-hand PET blowing machines revolves around the availability of technical support and warranty. However, reputed sellers of used machines often provide comprehensive after-sales support and warranty options. These services include troubleshooting assistance, spare parts availability, and expert guidance, ensuring a smooth operation of the acquired equipment.Enhancing Business Competitiveness:The ability to acquire cost-effective, reliable, and high-performing PET blowing machines allows businesses to enhance their competitiveness in the packaging industry. By reducing operational costs without compromising on quality, companies can offer competitive pricing to customers, thereby attracting new clients and expanding their market share. Moreover, the technological advancements of modern PET blowing machines, even in their second-hand state, enable increased production capacities and better product quality.Conclusion:With the packaging industry's booming demand for PET bottles, second-hand PET blowing machines present a viable solution for companies seeking to optimize their production processes effectively. The advantages of cost-effectiveness, environmental sustainability, reliability, reduced downtime, technical support, and enhanced competitiveness make the acquisition of second-hand machinery a wise decision for businesses. By embracing these advantages, companies can thrive in a highly competitive market while adhering to sustainable practices.

Advanced Techniques for Precision Bottle Extrusion Blow Molding

Bottle Extrusion Blow Molding: The Future of Innovative Packaging SolutionsIn today's highly competitive and fast-paced market, packaging plays a critical role in ensuring the success of a product. It is no longer enough to have a product that is high in quality and performance but ineffective in packaging. The packaging must be visually appealing, practical, and provide maximum product protection. This is where the Bottle Extrusion Blow Molding (need remove brand name) technology comes into play.Bottle Extrusion Blow Molding is a modern manufacturing process that produces high-quality plastic bottles in various shapes and sizes, suitable for an array of industries. The technology utilizes a preform that is heated and stretched to form the desired bottle shape. The preform is then injected with air to obtain the final product.One notable aspect of Bottle Extrusion Blow Molding technology is its cost-effectiveness. The production process removes the need for additional machinery and manpower, reducing operational costs significantly. Additionally, the process does not require substantial floor space, making it an ideal solution for small and medium-sized enterprises.The efficiency and speed of Bottle Extrusion Blow Molding make it capable of producing large quantities of bottles within short periods. The process can produce bottles with precise dimensions and negligible deviations, resulting in a consistent final product quality.Moreover, Bottle Extrusion Blow Molding technology can produce bottles with customized design features. Different colors, shape, labeling, and decorations can be incorporated into the bottles, creating visually appealing and distinctive products. This aspect gives brands the ability to differentiate themselves in the market, enhance brand recognition, and attract customers.The technology can be applied in a variety of industries, including the food and beverage industry, medical industry, automotive industry, and cosmetics industry. In food and beverage, the manufacturing process produces bottles that are resistant to pressure, air-tight for maximum shelf-life, and capable of withstanding high temperatures. The medical industry can utilize the technology to manufacture bottles that are sterile, and with tamper-evident sealing to provide maximum security. In the automotive industry, the process can be used to produce oil containers, transmission fluids, and brake fluid bottles that are capable of resisting chemical and mechanical stresses. Finally, the cosmetics industry can use Bottle Extrusion Blow Molding to produce stylish and aesthetically pleasing bottles suitable for high-end products.The success of Bottle Extrusion Blow Molding technology is not only assured by its innovative features but also by the expertise of the companies that provide the technology. One such company has over 20 years of experience in manufacturing plastic bottles and has invested in modern machinery and sophisticated technology to produce reliable, high-quality products. The company's large production capacity and commitment to quality have made it a trusted partner for businesses in various industries.In recent times, the company has seen an increase in demand for customized designs, and they have invested in digital printing capabilities. The company's customized printing technology allows for high-resolution images, including logos, text, and artwork, to be printed on the bottles, creating a visual impact and enticing potential customers.The innovative technology and expertise of the company have contributed to their clients' success, and they have become a market leader in the supply of plastic bottles. Their customer-oriented approach ensures that they work with clients every step of the way, from product design to production, and to final delivery. Additionally, the company has set up an extensive logistics network to ensure that products reach clients in a timely and cost-effective manner.In conclusion, Bottle Extrusion Blow Molding technology is a cost-effective, efficient, and customized solution to producing plastic bottles across various industries. The technology has revolutionized the manufacturing of plastic bottles through its ability to produce a consistent, quality final product in a short period. The technology, coupled with the expertise of the supplying companies, has created packaging solutions that enhance brand recognition and customer appeal. The future of innovative packaging solutions lies in Bottle Extrusion Blow Molding technology.