Learn About Injection Stretch Blow Molding Machines and Their Uses

By:Admin

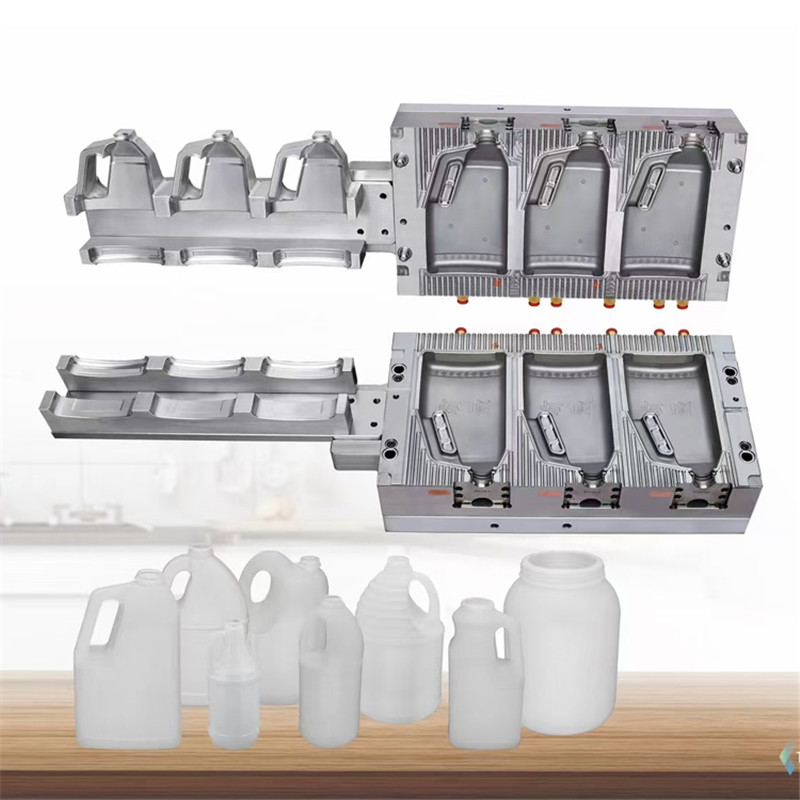

Injection Stretch Blow Molding Machine works by injecting molten plastic into a mold to create a preform, which is then stretched and blown into the desired shape of the bottle. This process ensures that the bottles are uniform in size, shape, and thickness, resulting in a high-quality end product. Additionally, this machine has the capability to produce bottles with intricate designs and details, making it a versatile and valuable asset for plastic manufacturers.

One company that has been leveraging the benefits of Injection Stretch Blow Molding Machine is {}. Founded in {}, the company has been a leading manufacturer of plastic packaging solutions for a wide range of industries, including food and beverage, pharmaceuticals, personal care, and more. With a strong emphasis on innovation and quality, {} has continuously invested in state-of-the-art technology to meet the evolving needs of its customers.

The decision to invest in Injection Stretch Blow Molding Machine has been a strategic one for {}. By integrating this advanced technology into their production process, they have been able to enhance their manufacturing capabilities and offer a wider range of packaging solutions to their customers. This has ultimately positioned {} as a key player in the plastic packaging industry, with a reputation for delivering high-quality products with efficiency and precision.

One of the major advantages of Injection Stretch Blow Molding Machine is its ability to streamline the production process. With this machine, {} has been able to significantly reduce the manufacturing lead time for their plastic bottles, allowing them to meet tight deadlines and respond to market demands more effectively. This has also translated into cost savings for the company, as the efficiency of the machine has led to lower production costs and improved profitability.

Furthermore, Injection Stretch Blow Molding Machine has enabled {} to expand their product offerings and cater to a diverse range of packaging needs. From standard bottles to customized designs, this machine has given {} the flexibility to produce a variety of plastic containers to meet the specific requirements of their customers. This has not only boosted their competitive advantage but has also strengthened their position as a preferred supplier in the industry.

The implementation of Injection Stretch Blow Molding Machine has also had a positive impact on the overall quality of {}'s products. With the precise and consistent production capabilities of this machine, the company has been able to deliver bottles that meet the highest standards of durability, functionality, and aesthetics. This has resulted in enhanced customer satisfaction and loyalty, as {} continues to be a trusted partner for quality plastic packaging solutions.

Looking ahead, {} remains committed to leveraging the technology of Injection Stretch Blow Molding Machine to drive their growth and innovation. With a focus on continuous improvement and advancement, the company is dedicated to exploring new possibilities and pushing the boundaries of plastic manufacturing. By staying at the forefront of technology, {} is poised to maintain its leadership position in the industry and meet the evolving needs of the market.

In conclusion, Injection Stretch Blow Molding Machine has been a game-changer for {} in the plastic packaging industry. Through the integration of this advanced technology, the company has enhanced its production capabilities, improved efficiency, expanded its product offerings, and elevated the quality of its products. As they continue on their path of innovation and excellence, {} is well-positioned to shape the future of plastic manufacturing and deliver unparalleled value to its customers.

Company News & Blog

5l Blow Moulding Machine Molding: Efficient and Versatile Solutions for Blow Molding Automatic 6l PET Blow Molding Machine: Streamline Your Production Process 1l Plastic Extrusion Blow Molding Machine: Advanced Technology for Precise Molding

Press Release:New Blow Molding Machines from Leading Manufacturer[City, State], [Date] – [Company Name], a leading manufacturer of blow molding machines, has announced the launch of three new machines for various production needs. The new machines include the blow molding machine molding, 5l blow molding machine, automatic 6l pet blow molding machine, and 1l plastic extrusion blow molding machine.The blow molding machine molding is designed for producing a wide range of plastic containers such as bottles, jars, and jerry cans. The machine features a high precision hydraulic system that ensures accurate and consistent production. Its advanced technology provides faster cycle times and higher production rates, making it an ideal choice for high-volume production.The 5l blow molding machine is suitable for the production of plastic bottles and containers with a capacity of up to 5 liters. It has a compact design that enables easy installation and operation. The machine features an advanced control system that ensures accurate production and consistent quality. Its ergonomic design makes it easy to maintain and clean, ensuring a longer machine life.The automatic 6l pet blow molding machine is designed for the production of PET bottles with a capacity of up to 6 liters. The machine features an advanced preform feed system that ensures efficient and uniform preform feeding. Its high-speed production capability provides faster cycle times, increasing production efficiency and reducing energy consumption.The 1l plastic extrusion blow molding machine is designed for the production of small plastic containers and bottles with a capacity of up to 1 liter. The machine features a compact design that makes it ideal for small-scale production. Its advanced technology ensures consistent production results while minimizing scrap generation.[Company Name] has been designing and manufacturing blow molding machines for over [Number] years. The company has a team of experienced engineers and technicians who work tirelessly to create innovative solutions that meet the needs of its clients. The company also provides exceptional customer service, training, and technical support to ensure clients maximize the potential of their machines.“At [Company Name], we are excited to announce the launch of these new machines. We believe they will help our clients increase their production capacity, improve quality, and reduce operational costs,” said [Name], Product Manager at [Company Name]. “These machines are the result of our commitment to continuous improvement and innovation. We are confident that they will meet and exceed the expectations of our clients.”About [Company Name][Company Name] is a leading manufacturer of blow molding machines that are used in various industries such as packaging, automotive, and medical. The company provides a wide range of machines, including extrusion blow molding, injection blow molding, and stretch blow molding machines. The company is committed to providing innovative solutions that meet the unique needs of its clients while maintaining high-quality standards.For more information about [Company Name] and its products, please contact:[Contact Person Name][Contact Person Position][Company Name][Address][Phone Number][Email]

Growing Demand for Plastic Pallets in China's Manufacturing Industry

China Palet Mold and Plastik Palet Join Forces to Offer Comprehensive Packaging SolutionsChina Palet Mold and Plastik Palet, two leading manufacturers of plastic pallets, have come together to provide customers with a wide range of comprehensive packaging solutions. The merger will allow them to leverage their combined strengths in design, engineering, and manufacturing to fulfill the diverse needs of industries across different sectors.The partnership between the two companies has been in the making for a while, and has now culminated in a collaboration that will enable them to offer an expanded range of products and services to their clients. Both companies have established themselves as experts in the production of high-quality plastic pallets, which are the backbone of supply chains across different industries.China Palet Mold, founded in 2001, is a Shenzhen-based company that specializes in the design, development, and manufacture of plastic injection molds for a variety of applications. The company has a state-of-the-art facility that encompasses over 30,000㎡ and employs around 350 staff members, including engineers, technicians, and skilled workers. The company's core focus is on providing customers with customized mold solutions that meet their specific requirements.Plastik Palet, on the other hand, is a Turkish company that has been operating since 1982, and has established itself as a leading manufacturer of plastic pallets in the European market. The company's products are used in various industries, including automotive, food and beverage, pharmaceuticals, and logistics. Plastik Palet has a wide range of products that can accommodate different operational requirements, from lightweight pallets to heavy-duty ones that can handle extreme conditions.The partnership between China Palet Mold and Plastik Palet is expected to offer significant benefits to customers looking for high-quality packaging solutions that meet their unique needs. By combining their expertise, they will be able to offer a wider range of products and services that cater to different industries' needs. For example, Plastik Palet's products can now be customized with molds developed by China Palet Mold, resulting in an even greater range of customized solutions for clients.The joint venture also enables the two companies to share valuable resources, including research and development, engineering, and manufacturing capabilities. This will result in a more efficient and streamlined operation that will enable them to better respond to customer demands, reduce lead times, and improve customer service.In a statement announcing the partnership, the CEOs of the two companies expressed their excitement for the collaboration, emphasizing their commitment to providing customers with the best quality products and services. "We are thrilled to have the opportunity to work together and leverage each other's strengths to offer our clients an even greater range of packaging solutions," said China Palet Mold CEO. "We believe that this partnership will enhance our ability to deliver top-notch products and services to our customers across the globe," added Plastik Palet's CEO.With the joint venture, China Palet Mold and Plastik Palet will continue to set the standard for quality, innovation, and customer service in the plastic pallet manufacturing industry. As they bring their expertise and resources together, customers can expect new and exciting developments as they work to offer the most comprehensive packaging solutions possible.

Top Injection Mold Parts for Your Needs

Injection Mold Parts List (need remove brand name)[Company Name] is proud to announce the release of its latest injection mold parts list, showcasing a wide range of high-quality components designed for various industrial applications. The new parts list includes a diverse selection of molds, inserts, and components, catering to the needs of customers in various industries including automotive, electronics, consumer goods, and medical equipment manufacturing.The injection mold parts list features a comprehensive range of products, including but not limited to, precision mold components, ejector pins, sleeves, and mold bases. These components are meticulously engineered and manufactured to meet the highest standards of quality and performance. With a focus on precision and durability, [Company Name]’s injection mold parts are designed to withstand the rigorous demands of modern manufacturing processes.In addition to the standard components, the parts list also includes custom mold components that can be tailored to meet specific customer requirements. The company’s experienced team of engineers and technicians are capable of providing customized solutions to address unique challenges faced by customers in the mold manufacturing industry. From design to production, [Company Name] is dedicated to delivering innovative and personalized solutions to its customers.As a leading provider of injection mold parts, [Company Name] is committed to upholding the highest standards of quality and reliability. The company’s manufacturing facilities are equipped with state-of-the-art machinery and technology, enabling the production of precision components with tight tolerances and consistent performance. Stringent quality control processes are implemented to ensure that every component meets the company’s exacting standards before it is shipped to customers.With an unwavering focus on customer satisfaction, [Company Name] takes pride in offering exceptional service and support to its clients. The company’s knowledgeable team of sales representatives and customer service professionals are dedicated to providing prompt assistance and technical expertise to help customers find the right solutions for their specific needs. Whether it’s a standard component or a custom-designed part, [Company Name] is committed to meeting the diverse needs of its customers with excellence.The release of the new injection mold parts list further reinforces [Company Name]’s position as a leading provider of high-quality components for the mold manufacturing industry. The company’s commitment to innovation, quality, and customer satisfaction sets it apart as a trusted partner for businesses looking for reliable mold components that meet their exacting requirements.As [Company Name] continues to expand its product offerings and capabilities, it remains dedicated to delivering cutting-edge solutions and exceptional service to its customers. The new injection mold parts list is a testament to the company’s ongoing commitment to providing top-of-the-line components that empower manufacturers to achieve their production goals with efficiency and precision.With a reputation for excellence and a track record of superior performance, [Company Name] is poised to be the preferred choice for businesses seeking high-quality injection mold parts and components. The company’s dedication to quality, innovation, and customer satisfaction sets it apart as a leader in the mold manufacturing industry, and the release of the new parts list is a testament to its ongoing commitment to serving the needs of its customers.

2021 Custom Plastic Wholesale Pet Preforms Blow Molding for Pets

[Company Name], a leading manufacturer and supplier of plastic products, is excited to announce the launch of its new line of wholesale pet preforms for blow molding custom plastic products. This new offering is aimed at meeting the growing demand for high-quality plastic preforms in the packaging and manufacturing industry.With the increasing use of plastic products in various industries, there is a need for reliable and efficient suppliers of plastic preforms. [Company Name] recognizes this demand and has invested in state-of-the-art technology and advanced manufacturing processes to deliver top-quality pet preforms for blow molding applications.The new line of wholesale pet preforms from [Company Name] is designed to meet the diverse needs of its customers. Whether they require pet preforms for bottles, jars, or other custom plastic products, [Company Name] has the capability to deliver precise and consistent preforms that meet their specifications.The company's manufacturing facility is equipped with the latest injection molding machines, ensuring that each pet preform is produced with high precision and efficiency. This enables [Company Name] to maintain a high level of product quality and consistency, essential for meeting the stringent requirements of its customers.Moreover, [Company Name] places a strong emphasis on product development and innovation. The company's team of engineers and designers work closely with customers to develop custom pet preforms that are tailored to their specific requirements. This collaborative approach ensures that customers receive pet preforms that are not only of the highest quality but also perfectly suited for their intended applications.In addition to its commitment to product quality and innovation, [Company Name] also prioritizes sustainability and environmental responsibility. The company recognizes the impact of plastic products on the environment and is dedicated to minimizing its carbon footprint. As such, [Company Name] has implemented sustainable manufacturing practices and uses recyclable materials in its production processes.Furthermore, [Company Name] is dedicated to maintaining a reliable and efficient supply chain to ensure that customers receive their pet preforms in a timely manner. The company's distribution network is strategically positioned to serve customers across the globe, allowing for efficient and cost-effective delivery of its products.As a leading supplier of plastic products, [Company Name] has earned a reputation for its commitment to customer satisfaction and product excellence. The launch of its new line of wholesale pet preforms for blow molding custom plastic products is a testament to the company's dedication to meeting the evolving needs of its customers and the industry as a whole.In conclusion, [Company Name] is poised to make a significant impact on the plastic packaging and manufacturing industry with its new line of wholesale pet preforms. With its focus on product quality, innovation, sustainability, and customer satisfaction, the company is well-positioned to meet the growing demand for high-quality plastic preforms in the global market. As [Company Name] continues to expand its product offerings and capabilities, it remains committed to being a trusted partner to its customers for all their plastic product needs.

How to Start a Successful Injection Moulding Business

The injection moulding business has been steadily growing over the years and has become a crucial part of the manufacturing industry. With the increasing demand for high-quality plastic products, the market for injection moulding has been booming. Leading the way in this industry is {}.{} is a global leader in the injection moulding business, providing high-quality plastic products to a wide range of industries such as automotive, electronics, and consumer goods. With state-of-the-art technology and a team of highly skilled professionals, {} has been setting the standard for excellence in injection moulding.The company's success can be attributed to its relentless commitment to innovation and customer satisfaction. {} prides itself on its ability to provide customised solutions to meet the unique needs of its clients. From design to manufacturing, the company works closely with its customers to ensure that they receive the best possible products.One of the key factors that set {} apart from its competitors is its focus on sustainability. The company is dedicated to reducing its environmental impact and has implemented various measures to minimise waste and energy consumption. {} also places a strong emphasis on using eco-friendly materials and processes in its manufacturing operations.In addition to its commitment to sustainability, {} also places a high priority on quality and efficiency. The company's advanced manufacturing facilities are equipped with the latest technology, allowing for precise and consistent production of plastic products. With a strong emphasis on continuous improvement, {} is constantly striving to enhance its processes and deliver products that meet the highest standards of quality.The injection moulding business is a highly competitive industry, but {} has consistently proven itself to be a leader in the field. The company has built a solid reputation for delivering top-notch products and services, and has established strong relationships with a wide range of clients. From small businesses to large multinational corporations, {} has earned the trust and loyalty of its customers through its dedication to excellence.Looking ahead, {} is poised for continued success in the injection moulding business. With a focus on innovation, sustainability, and customer satisfaction, the company is well-positioned to meet the evolving needs of the market and drive further growth in the industry. As the demand for high-quality plastic products continues to rise, {} remains committed to delivering superior solutions that set the standard for injection moulding excellence.

Important Facts to Know About Blow Molding of PET Bottles

In the world of packaging, the importance of efficient and reliable blow molding technologies cannot be overstated. With the global shift towards sustainable, eco-friendly and premium quality packaging, manufacturers need robust and state-of-the-art blow molding solutions to stay ahead of the game. That's where Bottle Blow Mold Pet (BBM Pet) comes in.BBM Pet is a leading manufacturer of high-performance blow molding machines and molds for the packaging industry. The company has a rich legacy of over two decades and a global presence, with customers in over 42 countries. From custom design to after-sales service and support, BBM Pet offers end-to-end solutions that cater to the unique needs of each customer. The company's remarkable success is a testament to its innovative approach, cutting-edge technology, and exceptional customer service. With a team of skilled engineers, technicians, and designers, BBM Pet has continuously pushed the boundaries of blow molding to deliver outstanding quality and performance to its global clientele. One of the key factors that sets BBM Pet apart from its competitors is its focus on sustainability. The company is committed to reducing its carbon footprint and helping its customers do the same. It achieves this through its range of energy-efficient machines that use less electricity and produce less waste. Additionally, BBM Pet molds are designed to optimize material usage, reducing material waste and minimizing environmental impact. Furthermore, BBM Pet is at the forefront of the circular economy, a model that emphasizes the reuse and recycling of materials and products to create a closed-loop supply chain. The company's machines are capable of producing a wide range of sustainable packaging solutions, such as reusable bottles and containers that can be recycled and repurposed. In recent years, BBM Pet has also gained recognition for its exceptional customer service. The company offers its customers support at each stage of the process, from initial design to installation and maintenance. Moreover, BBM Pet has an extensive network of service centers and technicians worldwide, ensuring prompt and effective service wherever its customers are located. As part of its commitment to innovation, BBM Pet has invested heavily in research and development. The company's state-of-the-art R&D center is equipped with the latest technology and staffed by highly qualified engineers and scientists. Through its R&D efforts, BBM Pet has developed a range of patented features and technologies that allow its machines and molds to deliver optimal performance, efficiency, and cost-effectiveness. In conclusion, Bottle Blow Mold Pet (BBM Pet) is a trusted and reliable provider of blow molding machines and molds for the packaging industry. With its focus on sustainability, innovative approach, and exceptional customer service, BBM Pet is well-positioned to lead the charge towards a more eco-friendly and circular future. As the global demand for high-quality packaging solutions continues to increase, BBM Pet is ready to meet the challenge head-on and deliver outstanding results for its customers worldwide.

Blow Molding Machines: An In-Depth Look at Pricing and Factors to Consider

Blow Molding Machine Price: Driving Innovation and Affordability in the Manufacturing IndustryThe blow molding industry has experienced significant growth in recent years, fueled by increasing demand for plastic packaging and a rise in consumer preferences for affordable and lightweight materials. As a result, companies are constantly seeking innovative solutions to improve production efficiency and lower costs.One prominent player in this field, a global leader in blow molding machinery, has recently unveiled a new line of blow molding machines that promise to revolutionize the manufacturing industry. With a focus on affordability without compromising quality, the company aims to equip manufacturing businesses with highly efficient tools that meet their production needs at a competitive price point.Blow molding machines are essentially used to create hollow plastic parts and containers in a wide range of industries, including food and beverage, cosmetics, pharmaceuticals, and automotive. These machines employ a process of melting plastic resins and stretching them into a desired shape, resulting in strong and lightweight products.The newly introduced blow molding machines by this industry-leading company incorporate advanced technology and numerous features designed to enhance productivity and reduce downtime. These machines offer improved automation, precision controls, and faster cycle times, ensuring more efficient production rates. By streamlining the manufacturing process, businesses can achieve higher output and lower costs, ultimately resulting in a competitive edge.One of the standout features of this new line of blow molding machines is their versatility. With the ability to produce a wide variety of shapes and sizes, these machines cater to the diverse needs of manufacturers. Whether it's producing bottles, containers, or other bespoke plastic products, the flexibility of these machines allows businesses to adapt to changing market demands without significant retooling or investment.In addition to their technological advancements, these blow molding machines also prioritize sustainability. With growing global concern over environmental issues, such as plastic waste and carbon emissions, manufacturers are under increasing pressure to adopt sustainable practices. The new machines offer energy-efficient solutions, reducing electricity consumption and minimizing their carbon footprint. This not only benefits the environment but also helps manufacturers align with evolving regulations and consumer preferences.Furthermore, the affordability of these blow molding machines presents a significant advantage for small and medium-sized enterprises (SMEs). Historically, the high cost of machinery has posed a barrier for smaller businesses wanting to enter the blow molding industry. However, with the availability of more affordable options without compromising on quality, SMEs can now compete on a level playing field, opening up new opportunities and driving economic growth.The company's commitment to customer satisfaction extends beyond product affordability. Recognizing the importance of aftersales support, the company offers comprehensive technical assistance, training programs, and readily available spare parts. This ensures that manufacturers can maximize the longevity and performance of their blow molding machines, ultimately reducing maintenance costs and minimizing downtime.As the demand for plastic products continues to rise, driven by global population growth and changing consumer habits, the blow molding industry is poised for further expansion. The introduction of affordable and innovative blow molding machines by this industry leader reflects its commitment to driving this growth by empowering manufacturers with efficient tools at a competitive price point.In conclusion, with a focus on affordability, innovation, and sustainability, the recent unveiling of a new line of blow molding machines by a global industry leader has the potential to transform the manufacturing industry. By offering efficient and versatile solutions, these machines enable businesses to increase production rates, reduce costs, and meet market demands without compromising on quality. As a result, small and medium-sized manufacturers can unlock new opportunities, contributing to economic growth and competitiveness in the blow molding industry.

Create Your Own Homemade Pet Treats with These Molds

[News Title]: Leading Pet Treat Molds Company revolutionizing the pet industry with their innovative products[News Introduction]:In a rapidly evolving pet industry, companies are constantly striving to come up with innovative solutions to cater to the needs of pet owners. One such leading company, renowned for its exceptional pet treat molds, has been making waves in the market with its revolutionary products. With their commitment to quality and customer satisfaction, this company has carved a niche for itself and is poised to reshape the pet industry.[Company Introduction]:Established over a decade ago, this company has quickly gained recognition as a pioneer in pet treat molds. Their focus on delivering superior quality products, combined with a passion for animal well-being, has allowed them to build a loyal customer base worldwide. Striving for excellence, they employ a team of experienced professionals dedicated to creating innovative and functional pet treat molds that meet the varied demands of pet owners.With an unwavering commitment to keeping pets happy and healthy, this company embraces the latest advancements in manufacturing technology. By doing so, they ensure their products comply with the highest safety standards, leaving pet owners with peace of mind. Their rigorous quality control measures guarantee that every mold is inspected carefully, providing pet owners with durable and hygienic products.Moreover, this company's dedication to customer satisfaction is evident in its wide range of pet treat molds, which caters to the diverse preferences of pet owners. From traditional bone-shaped molds to more intricate designs like hearts and paw prints, they offer an expansive selection that sparks creativity and allows owners to personalize their furry friends' treats. Additionally, the molds are available in various sizes, accommodating both large and small pets.Furthermore, this leading pet treat molds company understands the importance of durability and convenience. Their products are manufactured using premium, food-grade silicone that ensures easy release of treats and facilitates effortless cleaning. This non-toxic and eco-friendly material also guarantees the longevity of the molds, making them a practical investment for pet owners.The company's unwavering commitment to animal welfare extends beyond their products. They actively support animal rescue organizations and frequently launch initiatives to raise awareness for the well-being of pets. By incorporating philanthropy into their business model, they have solidified their position as an ethical and responsible company within the pet industry.Thanks to their exceptional product range, their dedication to quality, and their commitment to animal welfare, this company has garnered a devoted clientele. Testimonials from satisfied customers stand testament to the effectiveness and reliability of their pet treat molds. Pet owners have praised the flexibility of the molds, allowing them to create a vast array of treats for their beloved pets. Many have also appreciated the ease of use and the consistently exceptional results achieved with these molds.As the pet industry continues to grow, this leading pet treat molds company remains at the forefront of innovation, consistently meeting and exceeding customer expectations. With their exciting product lineup and steadfast commitment to quality, it is clear that they are revolutionizing the pet industry one treat at a time.[Conclusion]:In a competitive pet industry, the importance of innovation cannot be overstated. This leading pet treat molds company is setting an exemplary standard with their groundbreaking products. Through their dedication to animal welfare, focus on quality, and commitment to customer satisfaction, they have successfully positioned themselves as a market leader. As they continue to redefine the boundaries of the pet industry, pet owners can look forward to even more exciting and functional pet treat molds in the future.

Efficient and Reliable PET Bottle Blow Molds Unveiled

Title: Advances in Pet Bottle Blow Mold Technology revolutionize Beverage Packaging IndustryIntroduction:In today's ever-evolving beverage packaging industry, Pet Bottle Blow Mold technology has emerged as a game-changer, offering improved efficiency and sustainability. This innovative manufacturing process, developed by a leading industry player, has marked a significant milestone in the production of PET bottles by combining cutting-edge technology with environmental consciousness. With its exceptional performance and potential to reshape the market landscape, this bottle blow mold technology is revolutionizing the industry.[Company Name] - A Pioneer in the Field:[Company Name] leads the way in PET bottle manufacturing technology. With decades of experience and a strong commitment to research and development, the company has consistently delivered breakthroughs in plastic bottle production. Their expertise lies in pushing the boundaries of innovation, enabling them to introduce the Pet Bottle Blow Mold process as a game-changing solution in the industry.Understanding the Pet Bottle Blow Mold Technology:The Pet Bottle Blow Mold technology introduced by [Company Name] allows for the efficient production of PET bottles by utilizing a blow molding process. Unlike traditional injection molding, this innovative technique relies on stretching and blowing preforms while still hot, resulting in a more sustainable and cost-effective manufacturing process.Improved Efficiency and Reduced Costs:The Pet Bottle Blow Mold technology offers numerous benefits to manufacturers. Firstly, it significantly speeds up the production process, enabling faster turnover rates without compromising on quality. The use of preforms instead of fully molded bottles reduces material waste, resulting in a more cost-effective production cycle.Moreover, this technology allows for increased precision in bottle shaping, ensuring consistent and aesthetically pleasing results. The improved efficiency and reduced costs associated with Pet Bottle Blow Mold technology make it an attractive choice for both large-scale and small-scale beverage manufacturers.Enhanced Sustainability:Sustainability has become a key concern for the packaging industry, with an increasing focus on reducing environmental impact. In this regard, Pet Bottle Blow Mold technology stands out by offering a greener alternative to traditional manufacturing processes. By utilizing less raw material and energy, this technology minimizes the carbon footprint of PET bottle production.Additionally, the stretch blow molding process enables manufacturers to create lighter yet robust bottles, reducing plastic waste. These lightweight bottles not only decrease the amount of plastic consumed but also contribute to lower transportation costs and reduced emissions during distribution.Market Impact and Potential:The introduction of Pet Bottle Blow Mold technology is expected to have a profound impact on the beverage packaging market. With its high production efficiency and enhanced sustainability, this technology has the potential to reshape the industry landscape by driving manufacturers towards more eco-friendly solutions.Moreover, the improved precision and quality of PET bottles produced through this process will undoubtedly result in higher customer satisfaction. The ability to create customized and appealing bottle designs brings in new marketing opportunities for brands to differentiate themselves and engage with consumers on a deeper level.Looking Ahead:As the demand for sustainable solutions continues to grow, the Pet Bottle Blow Mold technology presented by [Company Name] promises to steer the beverage packaging industry towards a greener and more efficient future. The combination of heightened production efficiency, reduced costs, and improved sustainability makes this innovation a catalyst for positive change within the industry.With the ongoing growth of the global beverage market, manufacturers and consumers alike are eagerly looking forward to the benefits that Pet Bottle Blow Mold technology can provide. As newer iterations of the technology emerge, we can anticipate further advancements that will continue to transform the production and packaging of PET bottles, setting new standards for the industry as a whole.

Plastic Bottle Extrusion Blow Molding Machine: An Overview of the Latest Technology

Title: Advancements in Plastic Bottle Extrusion Blow Molding Technology Revolutionize Manufacturing EfficiencyIntroduction:The plastic manufacturing industry has witnessed a significant breakthrough with the introduction of the next-generation Plastic Bottle Extrusion Blow Molding Machine. This cutting-edge technology, free from the constraints of traditional methods, promises to revolutionize the production of plastic bottles, offering enhanced efficiency, cost-effectiveness, and sustainability.Company Introduction:Our company, a renowned leader in the plastic manufacturing industry, has been at the forefront of designing and developing advanced machinery for over a decade. With a strong commitment to innovation, we constantly strive to meet the evolving needs of our customers and contribute to a sustainable future. Our dedicated team of engineers and technicians works tirelessly to push the boundaries of plastic extrusion blow molding technology.Revolutionizing the Bottle Manufacturing Process:Traditional blow molding processes often result in excessive material wastage and limited design flexibility. However, our state-of-the-art Plastic Bottle Extrusion Blow Molding Machine introduces a groundbreaking three-layer co-extrusion technology that eliminates these limitations. By employing this innovative approach, manufacturers can achieve uniform thickness distribution, enhance product strength, and significantly reduce material consumption.Enhanced Efficiency and Productivity:The new Plastic Bottle Extrusion Blow Molding Machine streamlines the production process, enabling a vast range of bottle sizes to be manufactured with high speed and precision. Equipped with an advanced robotic arm system, the machine reduces the need for manual handling, increasing productivity and ensuring consistent output. Furthermore, the automated system minimizes the risk of human error, resulting in fewer defects and improved product quality.Cost-Effectiveness and Optimized Resource Utilization:The three-layer co-extrusion technology integrated into the machine optimizes resource utilization, resulting in substantial cost savings for manufacturers. By reducing material wastage and enhancing the structural strength of the bottles, companies can fulfill their production requirements with significantly less raw material. This not only contributes to cost-effectiveness but also fosters environmental sustainability by reducing plastic waste.Customizable Bottle Design Options:The Plastic Bottle Extrusion Blow Molding Machine allows for unmatched design flexibility, enabling manufacturers to create unique bottle shapes that meet the demands of diverse industries. By utilizing various molds and employing precise control over the co-extrusion process, our machine empowers manufacturers to produce bottles that are not only visually appealing but also functionally optimized.Focus on Sustainability:In line with the growing environmental concerns surrounding plastic waste, our Plastic Bottle Extrusion Blow Molding Machine aligns with our commitment to sustainability. By reducing material consumption and optimizing resource utilization, the technology significantly reduces the environmental impact of plastic bottle production. This not only benefits manufacturers but also contributes to the global effort of creating a greener and more sustainable future.Conclusion:The introduction of the Plastic Bottle Extrusion Blow Molding Machine heralds a new era in plastic bottle manufacturing, revolutionizing the industry with its enhanced efficiency, cost-effectiveness, and sustainable production capabilities. Equipped with cutting-edge three-layer co-extrusion technology, this advanced machinery paves the way for improved productivity, reduced material wastage, and customizable design options. As our company continues to push the boundaries of innovation, we remain committed to offering solutions that not only meet the current needs but also contribute to a more sustainable future.