Innovative Blow Molded Sand-Filled Kettlebell: A Functional Fitness Essential

By:Admin

Kettlebells have become a popular fitness tool due to their ability to provide a full-body workout and improve strength, stability, and endurance. With the increasing demand for home fitness equipment, a leading company in the fitness industry has introduced a new blow molded sand-filled kettlebell that is set to revolutionize the way people workout at home.

The company, based in (location), is known for its high-quality fitness products that are designed to meet the needs of both fitness enthusiasts and professional athletes. With a strong commitment to innovation and excellence, the company has been at the forefront of developing cutting-edge fitness equipment that delivers outstanding results.

The new blow molded sand-filled kettlebell is the latest addition to the company's extensive range of fitness products. Designed to provide a challenging and effective workout, this kettlebell is filled with sand using a blow molding process. This innovative technique ensures that the kettlebell has a durable and long-lasting construction, making it ideal for intense workout sessions.

One of the key features of this kettlebell is its ergonomic handle, which is designed to provide a comfortable and secure grip during workouts. This allows users to perform a wide range of exercises with confidence, knowing that the kettlebell will not slip or cause any discomfort. Additionally, the kettlebell is available in a range of weights, making it suitable for beginners and experienced fitness enthusiasts alike.

The company's commitment to quality is reflected in the design and construction of the blow molded sand-filled kettlebell. Made from high-quality materials, this kettlebell is built to withstand the demands of regular use, ensuring that it remains a reliable fitness tool for years to come. Furthermore, the sand filling provides a balanced weight distribution, allowing for smooth and controlled movements during workouts.

In addition to its outstanding performance, the blow molded sand-filled kettlebell is also designed with convenience in mind. Its compact size and versatile nature make it easy to store and use in a variety of spaces, whether at home or in a commercial fitness facility. This means that users can enjoy a challenging workout without the need for bulky or expensive equipment.

As the demand for home fitness equipment continues to grow, the introduction of the new blow molded sand-filled kettlebell comes at a perfect time. With its combination of durability, functionality, and convenience, this kettlebell is set to become a popular choice for individuals looking to enhance their fitness routine from the comfort of their own home.

The company's dedication to providing innovative fitness solutions is evident in the development of this kettlebell, and they are proud to offer a product that meets the needs of their customers. With a focus on quality and performance, they are committed to supporting individuals in achieving their fitness goals and leading a healthy lifestyle.

In conclusion, the introduction of the blow molded sand-filled kettlebell represents a significant milestone for the company, highlighting their ongoing commitment to delivering exceptional fitness products. As the demand for home fitness solutions continues to rise, this innovative kettlebell is well-positioned to meet the needs of users seeking a versatile, durable, and effective workout tool. With its ergonomic design, durable construction, and convenient size, the blow molded sand-filled kettlebell is set to make a positive impact on the fitness industry, providing individuals with the means to achieve their fitness goals on their own terms.

Company News & Blog

High-Quality Blow Moulding Machine for Water Tank Production

Water Tank Blow Moulding Machine: The Future of Plastic Water Tank ProductionIn recent years, the demand for plastic water tanks has been steadily increasing due to the growing need for water storage in residential, commercial, and industrial settings. This has led to a surge in innovation and technology within the plastics manufacturing industry, particularly in the development of more efficient and advanced production equipment.One of the leading companies at the forefront of this technological advancement is [Company Name]. With a strong reputation for providing high-quality and reliable machinery for the plastics industry, [Company Name] has recently introduced its latest innovation – the Water Tank Blow Moulding Machine.The Water Tank Blow Moulding Machine is a state-of-the-art piece of equipment designed to revolutionize the production of plastic water tanks. With its cutting-edge technology and advanced features, this machine is set to offer significant improvements in production efficiency, product quality, and overall cost-effectiveness.One of the key features of the Water Tank Blow Moulding Machine is its high-speed and high-precision capabilities. This machine is capable of producing water tanks of various sizes and shapes with exceptional precision and speed, resulting in a significant increase in production output. This is a game-changer for manufacturers in the plastics industry, as it allows them to meet the growing demand for water tanks more efficiently and effectively.Furthermore, the Water Tank Blow Moulding Machine is equipped with advanced automation and control systems, allowing for seamless operation and minimal human intervention. This not only improves the overall efficiency of the production process but also ensures consistent and high-quality results with every batch of water tanks produced.In addition to its impressive performance capabilities, the Water Tank Blow Moulding Machine is also designed with sustainability in mind. It utilizes energy-efficient technologies and materials, reducing energy consumption and environmental impact. This is an important consideration for manufacturers looking to align with sustainable practices and reduce their carbon footprint.With its innovative design and advanced features, the Water Tank Blow Moulding Machine is set to elevate the standards of plastic water tank production. [Company Name] is proud to be at the forefront of this industry transformation, offering manufacturers a cutting-edge solution to meet the evolving needs of the market.In summary, the introduction of the Water Tank Blow Moulding Machine by [Company Name] marks a significant milestone in the plastics manufacturing industry. This state-of-the-art machinery promises to revolutionize the production of plastic water tanks, offering unparalleled efficiency, quality, and sustainability. As the demand for water storage solutions continues to grow, the Water Tank Blow Moulding Machine is poised to play a crucial role in meeting this demand and shaping the future of the industry.

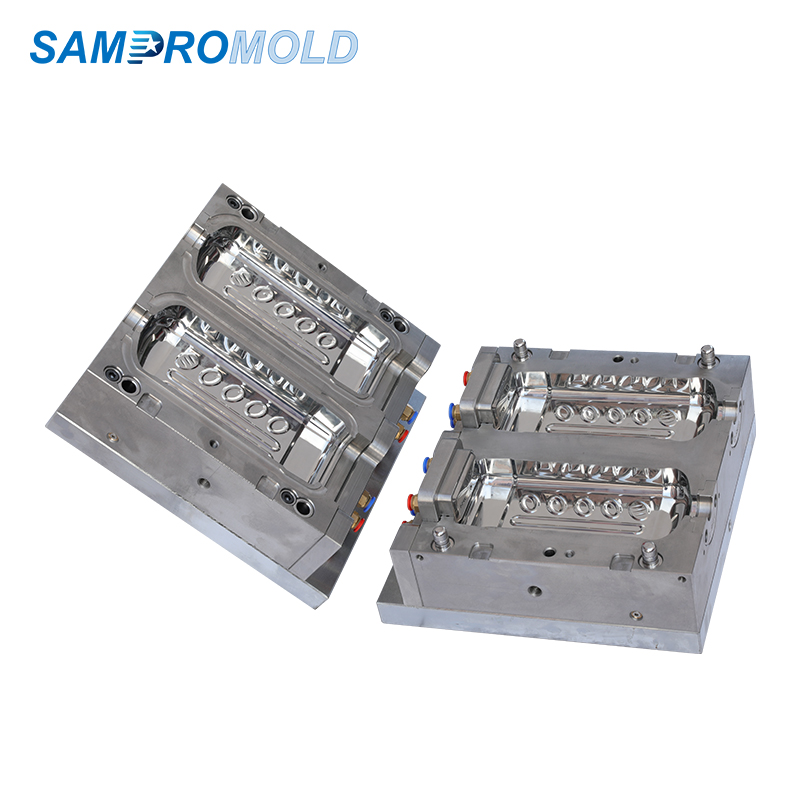

Top Plastic Injection Mould Manufacturer in the News

, focusing on the company's latest innovations, market expansion, and commitment to sustainability.Plastic Injection Mould Manufacturer, a global leader in the plastic injection molding industry, is proud to announce its latest innovations and market expansion strategies. With a strong commitment to sustainability, the company continues to revolutionize the industry with cutting-edge technology and environmentally friendly practices.With over [number of years] years of experience, Plastic Injection Mould Manufacturer has established itself as a trusted partner for businesses in various industries, including automotive, medical, consumer goods, and more. The company's dedication to quality and innovation has earned it a reputation for delivering top-of-the-line plastic injection molds and unparalleled customer service.In line with its mission to provide innovative solutions, Plastic Injection Mould Manufacturer has recently introduced a series of advanced molding technologies designed to meet the evolving needs of its clients. These technologies include breakthroughs in mold design, precision molding, and efficient production processes. By continuously investing in research and development, the company remains at the forefront of the industry, offering state-of-the-art solutions that drive its clients' success.Moreover, Plastic Injection Mould Manufacturer has expanded its market reach, establishing new partnerships and reaching new customers in key regions around the world. By leveraging its global network and strategic alliances, the company has been able to enhance its distribution capabilities and offer its cutting-edge solutions to a wider customer base. This expansion not only strengthens the company's position as a global leader but also enables it to better serve the needs of clients on a global scale.In addition to its focus on innovation and market expansion, Plastic Injection Mould Manufacturer remains deeply committed to sustainability. The company understands the importance of reducing its environmental impact and has implemented various initiatives to promote eco-friendly practices. Through the use of sustainable materials, energy-efficient processes, and waste reduction strategies, Plastic Injection Mould Manufacturer strives to minimize its carbon footprint and promote a greener future for the industry.Furthermore, Plastic Injection Mould Manufacturer actively seeks opportunities to collaborate with like-minded partners who share its commitment to sustainability. By working together with other industry leaders and organizations, the company aims to drive positive change and set new standards for environmental responsibility within the plastic injection molding industry. This collaborative approach reflects Plastic Injection Mould Manufacturer's belief in the power of partnership and collective action to address the challenges of sustainability.As Plastic Injection Mould Manufacturer continues to push the boundaries of innovation, expand its global presence, and champion sustainability, the company remains dedicated to delivering exceptional value to its customers. Through its relentless pursuit of excellence, Plastic Injection Mould Manufacturer is poised to shape the future of the plastic injection molding industry and lead the way towards a more sustainable and prosperous tomorrow.In conclusion, Plastic Injection Mould Manufacturer's latest innovations, market expansion, and commitment to sustainability underscore its leadership in the industry and its unwavering dedication to excellence. With a clear vision for the future and a steadfast commitment to meeting the evolving needs of its clients, Plastic Injection Mould Manufacturer continues to set the bar high for the industry, driving progress and shaping a brighter, more sustainable future for all.

Advanced Blow Machine Technology: A Look at the Latest Innovations in the Industry

The Blow Machine industry is witnessing substantial growth over the years, as the demand for efficient and high-quality blow molding machines continues to rise in various sectors such as packaging, automotive, and consumer goods. One company at the forefront of this industry is {}, a leading manufacturer of blow molding machines and related equipment.Established in the early 2000s, {} has proven itself to be a reliable and innovative player in the blow machine industry. The company specializes in the design, manufacturing, and distribution of a wide range of blow molding machines, including extrusion blow molding machines, injection blow molding machines, and stretch blow molding machines. With a strong focus on research and development, {} has been able to consistently introduce advanced technologies and solutions to meet the evolving needs of its customers.Recently, {} has introduced a new line of blow molding machines that are equipped with state-of-the-art features, setting a new standard for efficiency, productivity, and quality in the industry. The company's latest machines are designed to offer faster cycle times, lower energy consumption, and improved reliability, providing significant cost savings and performance benefits for its customers.In addition to its cutting-edge machines, {} also offers a comprehensive range of services to support its customers, including technical support, maintenance, and training programs. This customer-centric approach has helped {} to build long-term partnerships with clients across the globe, earning a reputation for excellence and reliability in the blow machine industry.As the demand for blow molding machines continues to grow, {} has been expanding its presence in key markets around the world. The company has established a strong global network of sales and service partners, allowing it to effectively reach and support customers in different regions. This strategic approach has enabled {} to serve a diverse range of industries, from food and beverage packaging to automotive components and industrial products.Moreover, {} is committed to sustainability and environmental responsibility, offering eco-friendly solutions that help its customers minimize their carbon footprint and reduce waste. The company's energy-efficient machines and recyclable materials contribute to a greener manufacturing process, aligning with the global trend towards more sustainable production practices.Looking ahead, {} is poised to continue its growth and innovation in the blow machine industry, leveraging its expertise and resources to address new challenges and opportunities in the market. From advanced technologies to exceptional service, {} is dedicated to providing its customers with the best solutions for their blow molding needs, driving success and efficiency in their production operations.With its strong track record and forward-thinking approach, {} remains a trusted and respected name in the blow machine industry, poised for further growth and success in the years to come. As the market evolves and demands continue to change, {} is well-positioned to lead the way in delivering cutting-edge solutions and exceptional value to its customers around the world.

Top Pet Extrusion Blow Molding Services for Quality Production

Pet Extrusion Blow Molding (need remove brand name) is revolutionizing the packaging industry with its innovative and sustainable approach to producing high-quality plastic containers. This cutting-edge technology allows for the creation of complex shapes and designs, making it the ideal solution for a wide range of industries including food and beverage, pharmaceuticals, personal care, and more.With over 20 years of experience in the packaging industry, Pet Extrusion Blow Molding (need remove brand name) has established itself as a leader in the field. The company prides itself on its commitment to quality, sustainability, and customer satisfaction. By utilizing state-of-the-art equipment and advanced manufacturing processes, Pet Extrusion Blow Molding (need remove brand name) is able to produce containers that are not only aesthetically pleasing but also durable and reliable.One of the key advantages of Pet Extrusion Blow Molding (need remove brand name) technology is its ability to create lightweight yet strong containers. This not only reduces material usage but also lowers transportation costs and carbon emissions. In addition, the company offers a range of sustainable and recyclable materials, further reducing its environmental impact.Furthermore, Pet Extrusion Blow Molding (need remove brand name) prides itself on its ability to provide customized packaging solutions to meet the specific needs of its clients. Whether it's a unique shape, size, or design, the company's team of experts can work with customers to develop a tailored solution that meets their exact requirements.In addition to its commitment to quality and sustainability, Pet Extrusion Blow Molding (need remove brand name) places a strong emphasis on customer satisfaction. The company strives to provide exceptional service and support to its clients, ensuring that their needs are met every step of the way. From concept development to production and delivery, Pet Extrusion Blow Molding (need remove brand name) is dedicated to exceeding customer expectations and building long-lasting partnerships.As a testament to its success, Pet Extrusion Blow Molding (need remove brand name) has garnered a loyal customer base and has established itself as a trusted partner in the packaging industry. Its track record of delivering high-quality products, innovative solutions, and exceptional customer service has set it apart from the competition.Looking to the future, Pet Extrusion Blow Molding (need remove brand name) is poised to continue leading the way in the packaging industry. The company is committed to staying at the forefront of technological advancements, ensuring that it can continue to meet the evolving needs of its customers and the ever-changing demands of the market.In conclusion, Pet Extrusion Blow Molding (need remove brand name) is a company that is redefining the packaging industry with its innovative and sustainable approach to producing high-quality plastic containers. With a strong commitment to quality, sustainability, and customer satisfaction, the company has established itself as a leader in the field and is well-positioned to continue its success in the future.

Discover the Latest Innovation in Blow Molded Pots

Title: Revolutionizing Gardening with High-Quality Blow Molded PotsIntroduction:In today's fast-paced world, cultivating plant life has become more popular than ever. With people finding solace in gardening, the demand for innovative products like blow molded pots has soared. One industry-leading company has recognized this growing need and introduced a wide range of high-quality blow molded pots designed to enhance the gardening experience. This article will delve into the features, benefits, and the company's commitment to sustainability and customer satisfaction.Product Features:The blow molded pots offered by [Company Name] are revolutionizing the gardening industry through their exceptional features. Their pots are manufactured using a blow molding process, which ensures durability and resistance to harsh weather conditions. The pots are made from recyclable materials, reducing their environmental impact while providing gardeners with long-lasting products.One noteworthy feature is the lightweight nature of these pots, making them easy to transport and handle during planting and rearranging. Additionally, the pots are UV-resistant, protecting plants from harmful sun rays whilst maintaining their vibrant colors over time.The blow molded pots come in various sizes, catering to the diverse needs of gardeners. Whether it's small pots for herb gardens or large pots for trees, [Company Name] offers a wide range of options to suit all gardening requirements.Product Benefits:Gardening enthusiasts will enjoy several benefits when choosing blow molded pots by [Company Name]. Primarily, the durability and high-quality construction ensure these pots can withstand the test of time, providing a stable home for plants throughout their growth.The UV-resistant feature prevents fading and discoloration, allowing plants to thrive without compromising their aesthetic appeal. Furthermore, the lightweight nature of the pots facilitates easy movement, perfect for those who wish to rearrange their garden setup regularly.As these pots are manufactured from recyclable materials, gardeners can contribute to environmental sustainability by opting for eco-friendly products. With [Company Name], customers not only invest in reliable planting solutions but also actively participate in conserving the planet.Company Commitment to Sustainability:[Company Name] is dedicated to producing blow molded pots while minimizing its environmental footprint. Through an emphasis on responsible manufacturing practices, the company has implemented strategies to recycle and reuse materials throughout its product line. By doing so, they strive to reduce waste and promote a circular economy.In addition to using recyclable materials, [Company Name] prioritizes energy efficiency during the production process. They actively seek to minimize energy consumption, thereby reducing greenhouse gas emissions. Such initiatives highlight their commitment to sustainability and align with the increasing global focus on eco-consciousness.Customer Satisfaction:[Company Name] places customer satisfaction at the core of their business. They prioritize quality control, ensuring that each blow molded pot meets rigorous standards before reaching the market. By focusing on providing durable and reliable products, they aim to exceed customer expectations.Moreover, the company values customer feedback and uses it to continuously improve their offerings. By actively listening to their customers, [Company Name] demonstrates their commitment to understanding and meeting the needs of gardeners.Conclusion:Blow molded pots offered by [Company Name] are transforming the gardening experience with their impressive features and benefits. Their commitment to sustainability, durability, and customer satisfaction proves that they are at the forefront of innovation in the industry.As more individuals seek solace in gardening, these high-quality blow molded pots will undoubtedly conquer the market, empowering gardeners with the ideal planting solution. From the eco-conscious production process to the extensive product range, [Company Name] is unquestionably setting a new standard in the world of gardening.

New Technology Makes Plastic Jar Production Faster and More Efficient

Pet Jar Blow Moulding Machine- The Future of Plastic Jar ManufacturingPlastic jars have become a ubiquitous item in our daily lives- from storing cosmetics to food items, these jars have become a staple in all our homes and businesses. Over the years, the process of manufacturing plastic jars has evolved to become more efficient, streamlined, and environmentally friendly. The Pet Jar Blow Moulding Machine is the latest innovation in the manufacturing process of plastic jars, catering to the ever-rising demand for sustainable, high-quality plastic jars.The Pet Jar Blow Moulding Machine is a cutting-edge technology that offers a comprehensive range of benefits, ranging from faster production rates to reduced wastage and lower energy consumption. It is a versatile machine that is capable of producing a wide variety of plastic jars with exceptional precision and quality. The machine is equipped with the latest technology that makes it highly flexible and customizable, enabling manufacturers to produce plastic jars of different sizes, shapes, and specifications.Managed by a highly skilled workforce, Pet Jar Blow Moulding Machine manufacturers the best quality plastic jars for different industries like food and beverage, cosmetic, and pharmaceuticals. The machine is capable of producing PET jars of different types, including round, square, and rectangular. It is the go-to machine for businesses looking for reliable, high-quality plastic jar manufacturing services.The introduction of the Pet Jar Blow Moulding Machine has revolutionized the process of plastic jar manufacturing by making it more streamlined and cost-effective. Apart from this, it is also environmentally friendly as it consumes less energy compared to its conventional counterparts. The machine operates at a lower temperature, providing manufacturers with a more energy-efficient production process.One of the significant advantages of the Pet Jar Blow Moulding Machine is that it has a faster production rate, leading to a higher volume of production within a shorter time. With the rise in demand for plastic jars, businesses require a machine that can keep up with this demand. This is where the Pet Jar Blow Moulding Machine comes in handy, as it can produce up to 5,000 units per hour, making it an ideal machine for businesses with high production requirements.Furthermore, the Pet Jar Blow Moulding Machine focuses on producing sustainable products, thereby reducing the impact of plastic on the environment. The machine uses PET resin material, which is an environmentally friendly material that can be recycled to produce other products. Because of this, the Pet Jar Blow Moulding Machine is a sustainable solution to plastic jar manufacturing, ensuring that businesses are not only producing high-quality plastic jars but are also doing so in an environmentally responsible manner.The Pet Jar Blow Moulding Machine has several features that set it apart from its conventional counterparts. The machine has an adjustable speed mechanism, a high heating capacity, and an automated control system that allows for greater precision, consistency, and reliability. Additionally, the machine is easy to operate and maintain, making it an ideal machine for small businesses or enterprises with low technical expertise.In conclusion, the Pet Jar Blow Moulding Machine is the ideal solution for businesses looking to produce high-quality, sustainable plastic jars. The machine is ideal for businesses that require a high rate of production, minimal wastage, and lower energy consumption. With its cutting-edge technology and the ability to produce plastic jars of different sizes and shapes, the machine is the future of plastic jar manufacturing. As businesses continue to shift towards sustainability, the Pet Jar Blow Moulding Machine offers a sustainable solution to plastic jar manufacturing, thereby reducing the impact of plastic on the environment.

Efficient and Advanced Detergent Bottle Blow Molding Machine Unveiled

Detergent Bottle Blow Molding Machine- A Revolutionary Solution for Efficient ProductionWith the increasing demand for detergents in the market, it has become essential for companies to explore and develop new technologies to streamline their production processes. One such technology that has gained immense popularity in recent times is the Detergent Bottle Blow Molding Machine.This machine is a revolutionary solution that has proved to be an efficient option for manufacturers in the detergent industry. It is designed to mold plastic into bottles of various shapes and sizes for different detergents. The machine is equipped with advanced features that enhance the efficiency and speed of production while minimizing energy consumption. One of the most significant advantages of this machine is that it produces bottles with high consistency, rigidity, and accuracy. The Detergent Bottle Blow Molding Machine can produce bottles with complex shapes, curves, and designs, making it a perfect fit for branding needs. Additionally, the machine's speed can be controlled using automation, which helps minimize errors, ultimately producing top-quality bottles.Machines produced by different manufacturers may vary slightly in design; however, they all share some common features which make them a go-to solution for most manufacturers. The features include a PLC control system, potentiometer, working status indicators, multi-layer cooling with optional chiller, tri-axes linear guide rail, and photoelectric protection that ensures sufficient safety for operators.With all these incredible features, the Detergent Bottle Blow Molding Machine is a cost-efficient option for manufacturers. It produces high-quality bottles at a faster rate with minimal energy expenditure, resulting in a higher return on investment. Manufacturers can save time and money, and minimal human labor is required, making it a perfect fit for high-volume production.One of the key companies currently offering these machines is {}. The company is renowned for its innovative designs and top-quality production. They have invested heavily in research and development and have come up with advanced machines that cater to every need in the detergent industry.With a team of experts and decades of experience in the production of machinery, this company has created some of the best machines in the market. The Detergent Bottle Blow Molding Machine is one of their latest designs. It has been thoroughly tested and approved by industry experts, and many users have already given glowing reviews of its performance.The company not only produces the machines but also provides an extensive after-sales service. Their team of experts is always ready to offer advice and support on any issue you may be experiencing. Additionally, they provide training to operators to ensure a smooth production process while minimizing incidents of downtime. In conclusion, the Detergent Bottle Blow Molding Machine is a revolutionary solution for the detergent industry. It has proved to be an efficient option for manufacturers, producing high-quality bottles with minimal energy expenditure and minimal labor. The machine is equipped with advanced features that enhance efficiency and speed, which translates to higher returns on investment. Companies like {} are at the forefront of producing top-quality Detergent Bottle Blow Molding Machines, and with their excellent after-sales service, you can be sure to get the support you need.

High-Quality 2-4 Cavity Pet Blow Mold Machine Now Available in Canada

Title: Canadian Company Unveils Advanced 2-4 Cavity Pet Blow Mold MachineIntroduction:In a significant stride towards technological innovation, a renowned Canadian manufacturer, having established a strong presence in the field of industrial machinery, has launched an advanced 2-4 cavity PET blow mold machine. With the aim of revolutionizing the packaging industry, this cutting-edge equipment promises to increase efficiency and productivity while minimizing energy consumption and maintenance requirements. By combining the latest technological advancements with their extensive expertise, this Canadian company is set to reshape the landscape of blow molding machinery.Innovation at its Finest:The newly unveiled 2-4 cavity PET blow mold machine comes as a result of extensive research and development efforts by the talented engineers at the Canadian company. With a focus on delivering state-of-the-art solutions, this machine is equipped with advanced features that ensure superior performance and exceptional output quality.Improved Efficiency and Productivity:One of the key highlights of this PET blow mold machine is its ability to enhance efficiency and productivity levels for manufacturers. By utilizing an innovative preform heating system, this equipment achieves faster heating rates and optimized energy consumption. This translates into reduced cycle times, enabling higher production volumes without compromising the overall quality of the output.Additionally, the machine's precise control of mold closing and opening reduces the time required for mold changes, resulting in improved overall productivity. The 2-4 cavity configuration further enables simultaneous production runs, maximizing output rates and time efficiencies for manufacturers.Energy-Saving and Cost-Effective:In line with the growing emphasis on sustainability and environmentally friendly practices, the Canadian company has integrated several energy-saving features into their PET blow mold machine. By employing advanced technologies such as infrared ceramic heaters and efficient cooling systems, this equipment significantly reduces energy consumption, leading to substantial cost savings for manufacturers.Moreover, the machine's low maintenance requirements and high durability ensure a cost-effective approach for businesses. The use of high-quality components and the implementation of advanced engineering techniques guarantee a longer lifespan, minimizing the need for frequent maintenance or replacements.Quality Assurance and Flexibility:Recognizing the importance of maintaining impeccable product quality, the Canadian company has incorporated several features aimed at ensuring the highest standards.The 2-4 cavity PET blow mold machine is equipped with automatic temperature control and advanced servo-driven components that enable precise control over the blowing process. This guarantees consistent bottle integrity, uniform wall thickness, and accurate neck finishes, allowing manufacturers to deliver products of superior quality.Furthermore, the machine's flexibility allows for the production of a wide range of bottle sizes, shapes, and designs. From small containers to larger packaging solutions, this equipment accommodates diverse requirements, catering to the ever-evolving needs of packaging manufacturers.Market Impact and Future Prospects:The launch of the 2-4 cavity PET blow mold machine by the Canadian company is expected to have a significant impact on the packaging industry. Manufacturers will benefit from enhanced productivity, cost savings, and improved product quality, giving them a competitive edge in the market.Looking ahead, the Canadian company plans to amplify its research and development efforts, aiming to continuously refine and expand its range of blow molding machinery. By staying at the forefront of technological advancements, the company aims to solidify its position as a global leader in providing innovative and sustainable packaging solutions.Conclusion:With the introduction of their state-of-the-art 2-4 cavity PET blow mold machine, the Canadian company has taken a major step towards revolutionizing the packaging industry. This advanced equipment promises enhanced efficiency, increased productivity, cost savings, and superior product quality. By leveraging cutting-edge technology and their expertise, this company is paving the way for a more sustainable and innovative future in the field of packaging manufacturing.

Highly Efficient and Durable Blow Molding Clamping Unit for Pet Products

Pet Blow Molding Clamping Unit is the latest innovation from our company, a leading manufacturer of high-quality plastic packaging solutions. This new clamping unit is designed to provide our customers with superior performance and unmatched reliability, further solidifying our position as a trusted industry leader.The new Pet Blow Molding Clamping Unit is the result of years of research and development, leveraging our expertise in plastic molding technology. The clamping unit is designed to meet the growing demand for efficient, high-speed production in the packaging industry. It offers a range of impressive features that set it apart from other clamping units on the market, making it the ideal choice for businesses looking to optimize their production processes.One of the key highlights of the Pet Blow Molding Clamping Unit is its advanced design, which ensures precise and consistent clamping force during the molding process. This results in superior product quality and minimizes the risk of defects or inconsistencies in the final output. The unit also boasts a high level of adaptability, allowing for seamless integration into existing production lines, making it a versatile and practical solution for businesses looking to upgrade their operations.In addition to its superior performance, the Pet Blow Molding Clamping Unit is designed with the user in mind. It features a user-friendly interface and intuitive controls, making it easy to operate and maintain. This not only enhances productivity but also reduces the need for extensive training, ultimately lowering operational costs for our customers.Another significant benefit of the Pet Blow Molding Clamping Unit is its energy efficiency. Our team of engineers has incorporated innovative technology to minimize energy consumption during operation, helping businesses reduce their carbon footprint and lower their overall manufacturing costs.Furthermore, the clamping unit is built to last, constructed from high-quality materials and components that ensure durability and reliability. This minimizes downtime and maintenance requirements, allowing businesses to enjoy continuous production with minimal disruptions.The introduction of the Pet Blow Molding Clamping Unit reaffirms our commitment to providing cutting-edge solutions that empower our customers to achieve their production goals efficiently and cost-effectively. This new offering complements our extensive range of plastic packaging solutions, including blow molding machines, injection molding machines, and ancillary equipment, all of which are designed to meet the diverse needs of our global customer base.As a company, we take pride in our ability to deliver superior products and support services that drive our customers' success. Our team's extensive expertise and dedication to innovation have made us a trusted partner for businesses seeking reliable and high-performance plastic packaging solutions.The launch of the Pet Blow Molding Clamping Unit represents a significant milestone for our company, marking our continued growth and leadership in the industry. We are confident that this new offering will empower our customers to enhance their production capabilities and achieve sustainable growth in the competitive packaging market.Moving forward, we remain committed to advancing the boundaries of plastic molding technology, continuously striving to develop innovative solutions that address the evolving needs of the industry. With a focus on quality, performance, and sustainability, we aim to set new standards for excellence in plastic packaging, further strengthening our position as a preferred partner for businesses worldwide.In conclusion, the Pet Blow Molding Clamping Unit stands as a testament to our unwavering commitment to delivering value-driven solutions that empower our customers to succeed in their respective markets. With its advanced features, user-friendly design, and exceptional performance, this new offering is set to redefine the standard for clamping units in the packaging industry, setting a new benchmark for efficiency, reliability, and overall productivity. We are excited to see the positive impact that the Pet Blow Molding Clamping Unit will have on our customers' operations and look forward to continued collaboration and success in the years to come.

Latest Advancements in Blow Molding Machine Technology: Injection Stretch Innovation

Blow Molding Machine Injection Stretch Technology Leads to Efficiency and Precision in ProductionBlow molding is a process commonly used in manufacturing plastic products such as bottles, containers, and automotive parts. Recently, the industry's demand for greater efficiency and precision in production has led to the development of blow molding machines that incorporate injection stretch technology. One particular company at the forefront of this emerging trend is a leading manufacturer of blow molding machines, whose machines have been adopted by major players in industries such as packaging, automotive, and consumer goods.The combination of blow molding and injection stretch technology offers manufacturers a multitude of benefits. Injection stretch technology allows for the creation of more complex shapes and thinner walls for products, without sacrificing strength and durability. This technology uses a preform injection process, which involves melting a plastic material and then injecting it into a mold where it is stretched beyond its elastic limit to achieve the desired shape. This process results in products with improved precision in distribution of material and enhanced surface quality.The combination of blow molding and injection stretch technology also results in increased efficiency in production. The two processes can be carried out simultaneously in the same machine, reducing the number of steps required for producing a finished product. This not only saves time but also reduces the chances of defects or errors during the manufacturing process.Furthermore, the use of advanced technologies in blow molding machines improves safety and reduces environmental impact. The machines are equipped with features such as automatic shutdown systems to prevent accidents, as well as energy-saving mechanisms that reduce power consumption. Their closed-loop hydraulic systems also reduce the amount of oil required for operation, contributing to a cleaner and greener environment.The leading manufacturer of blow molding machines has been at the forefront of developing machines that combine blow molding and injection stretch technologies. Their machines have shown impressive results, both in terms of production efficiency and product quality. One major beverage company that adopted this technology has reported an increase in productivity by as much as 30%, thanks to reduced cycle times and increased output. These results demonstrate the value of adopting advanced technologies in manufacturing, and signify a shift towards a more efficient and sustainable manufacturing industry.Apart from developing advanced technologies in blow molding, the leading manufacturer also emphasizes on its customer-centric approach, offering tailor-made solutions that correspond to specific needs for individual customers. Their state-of-the-art facilities are equipped with a team of experts who are always engaging in research and development to ensure clients attain their individual production requirement goals.Furthermore, the company has a well-established after-sales service team to support customers after the purchase of the machines. The technical team provides customers with comprehensive training programs on machine operations and maintenance procedures. Their clientele has cited satisfaction with the level of technical support they receive from this manufacturer, which contributes to the longevity and performance of the machines and reinforces a long-lasting relationship between the manufacturer and the customers.In conclusion, the integration of blow molding and injection stretch technologies is a remarkable advancement in the manufacturing industry. These advances in technology presented by the leading manufacturer of blow molding machines have provided manufacturers with enhanced precision, improved productivity and established environmental-conscious manufacturing practices. Additionally, their customer-centric approach coupled with their well-trained and qualified technical team ensures their clients receive not only quality, advanced technology machines, but also exceptional post-purchase customer support. As industries continue to demand higher and more efficient production standards, adopters of blow molding machines in combination with injection stretch technology will continue to give companies an edge over the competition in product quality, production efficiency, and higher customer satisfaction.