Injection Blow Molding Machine for Bottles: What You Need to Know

By:Admin

The Bottle Injection Blow Molding Machine is a state-of-the-art equipment that is designed to produce high-quality plastic bottles for various industries such as food and beverage, pharmaceutical, and cosmetic. It uses advanced injection and blow molding technology to create bottles with precise dimensions and excellent finish. The machine is also equipped with intelligent control systems that ensure consistent production and minimal wastage.

The company behind the development of this groundbreaking machine, has been a pioneer in the manufacturing industry for over two decades. With a strong focus on research and development, the company has consistently introduced innovative solutions to address the evolving needs of the industry. The introduction of the Bottle Injection Blow Molding Machine is a testament to the company's commitment to excellence and its dedication to pushing the boundaries of technology.

The machine has garnered attention from manufacturers around the world for its ability to significantly improve production efficiency and reduce costs. Its precision and consistency in producing high-quality bottles have made it a top choice for companies looking to enhance their manufacturing capabilities. The machine's intelligent control systems also contribute to its appeal, as they allow for seamless operation and minimal downtime.

In addition to its technical capabilities, the Bottle Injection Blow Molding Machine is also designed with user-friendly features that make it easy to operate and maintain. Its intuitive interface and ergonomic design ensure a smooth and hassle-free production process, allowing operators to maximize their productivity and focus on other aspects of production.

The company's dedication to customer satisfaction is also evident in its comprehensive after-sales support. It provides training and technical assistance to ensure that customers can fully utilize the capabilities of the machine. Additionally, the company offers a range of customization options to tailor the machine to the specific needs of its customers, further solidifying its reputation as a trusted partner in the industry.

Furthermore, the Bottle Injection Blow Molding Machine is also environmentally friendly, as it is designed to minimize energy consumption and reduce waste. Its efficient production process and minimal material wastage contribute to a more sustainable manufacturing practice, aligning with the growing demand for eco-friendly solutions in the industry.

The company's commitment to innovation and excellence has positioned it as a leader in the manufacturing industry. Its continuous investment in research and development has enabled it to introduce game-changing solutions such as the Bottle Injection Blow Molding Machine, which is set to redefine the production of plastic bottles.

As the demand for high-quality plastic bottles continues to grow, the Bottle Injection Blow Molding Machine is poised to become an indispensable asset for manufacturers looking to stay ahead in the competitive market. Its precision, efficiency, and user-friendly design make it a valuable investment for companies seeking to enhance their production capabilities.

In conclusion, the Bottle Injection Blow Molding Machine, developed by an industry-leading company, is a game-changing solution that offers precision, efficiency, and sustainability in the production of plastic bottles. With its advanced technology and user-friendly features, it is set to revolutionize the manufacturing industry and become an essential asset for companies aiming to elevate their production capabilities.

Company News & Blog

High-Quality Blow Molding Machine Cylinders for Efficient Production

Blow molding is a widely used manufacturing process in the production of plastic containers, bottles, and other hollow shapes. This process involves melting plastic and then shaping it into a hollow form by using air pressure. Blow molding machines are essential equipment in this process, as they help in creating the desired shapes and sizes of the products.One of the key components of a blow molding machine is the cylinder, which plays a crucial role in the overall functioning of the machine. The cylinder is responsible for controlling the movement of the plastic material, allowing for precise and accurate shaping of the final product. It is important for the cylinder to be of high quality and durable, as it directly impacts the efficiency and reliability of the blow molding machine.Recently, the company {} have developed a new line of blow molding machine cylinders that are set to revolutionize the industry. With their years of experience and expertise in manufacturing high-quality components for the plastic industry, they have introduced a range of cylinders that boast advanced technology and innovative features.These new cylinders are designed to offer superior performance, reliability, and efficiency, making them an ideal choice for blow molding machine manufacturers and operators. The cylinders are engineered to withstand the high pressures and temperatures involved in the blow molding process, ensuring consistent and precise control over the plastic material. This results in the production of high-quality plastic products with uniform shapes and dimensions.In addition to their exceptional performance, the new line of cylinders from {} are also designed with ease of maintenance and servicing in mind. They are equipped with features that allow for quick and easy access for cleaning and maintenance, reducing downtime and increasing overall productivity. This is a crucial factor for manufacturers and operators who rely on their blow molding machines to run continuously and efficiently.Furthermore, {} is dedicated to providing excellent customer support and service, ensuring that their clients receive the necessary assistance and guidance in choosing the right cylinders for their specific requirements. This level of support is valuable for manufacturers and operators who are looking to upgrade their existing blow molding machines or invest in new equipment.With the introduction of their new line of blow molding machine cylinders, {} is poised to make a significant impact in the industry. Their commitment to innovation, quality, and customer satisfaction sets them apart as a leading provider of components for the plastic manufacturing sector. The new cylinders are set to elevate the performance and efficiency of blow molding machines, ultimately benefiting manufacturers, operators, and end-users.In conclusion, the development of advanced blow molding machine cylinders by {} represents a major milestone in the industry. Their new line of cylinders is designed to deliver unmatched performance, reliability, and efficiency, setting a new standard for the manufacturing of plastic containers and bottles. With their commitment to quality and innovation, {} is set to play a key role in shaping the future of blow molding technology.

High-Quality Blow Moulding Machine for Water Tank Production

Water Tank Blow Moulding Machine: The Future of Plastic Water Tank ProductionIn recent years, the demand for plastic water tanks has been steadily increasing due to the growing need for water storage in residential, commercial, and industrial settings. This has led to a surge in innovation and technology within the plastics manufacturing industry, particularly in the development of more efficient and advanced production equipment.One of the leading companies at the forefront of this technological advancement is [Company Name]. With a strong reputation for providing high-quality and reliable machinery for the plastics industry, [Company Name] has recently introduced its latest innovation – the Water Tank Blow Moulding Machine.The Water Tank Blow Moulding Machine is a state-of-the-art piece of equipment designed to revolutionize the production of plastic water tanks. With its cutting-edge technology and advanced features, this machine is set to offer significant improvements in production efficiency, product quality, and overall cost-effectiveness.One of the key features of the Water Tank Blow Moulding Machine is its high-speed and high-precision capabilities. This machine is capable of producing water tanks of various sizes and shapes with exceptional precision and speed, resulting in a significant increase in production output. This is a game-changer for manufacturers in the plastics industry, as it allows them to meet the growing demand for water tanks more efficiently and effectively.Furthermore, the Water Tank Blow Moulding Machine is equipped with advanced automation and control systems, allowing for seamless operation and minimal human intervention. This not only improves the overall efficiency of the production process but also ensures consistent and high-quality results with every batch of water tanks produced.In addition to its impressive performance capabilities, the Water Tank Blow Moulding Machine is also designed with sustainability in mind. It utilizes energy-efficient technologies and materials, reducing energy consumption and environmental impact. This is an important consideration for manufacturers looking to align with sustainable practices and reduce their carbon footprint.With its innovative design and advanced features, the Water Tank Blow Moulding Machine is set to elevate the standards of plastic water tank production. [Company Name] is proud to be at the forefront of this industry transformation, offering manufacturers a cutting-edge solution to meet the evolving needs of the market.In summary, the introduction of the Water Tank Blow Moulding Machine by [Company Name] marks a significant milestone in the plastics manufacturing industry. This state-of-the-art machinery promises to revolutionize the production of plastic water tanks, offering unparalleled efficiency, quality, and sustainability. As the demand for water storage solutions continues to grow, the Water Tank Blow Moulding Machine is poised to play a crucial role in meeting this demand and shaping the future of the industry.

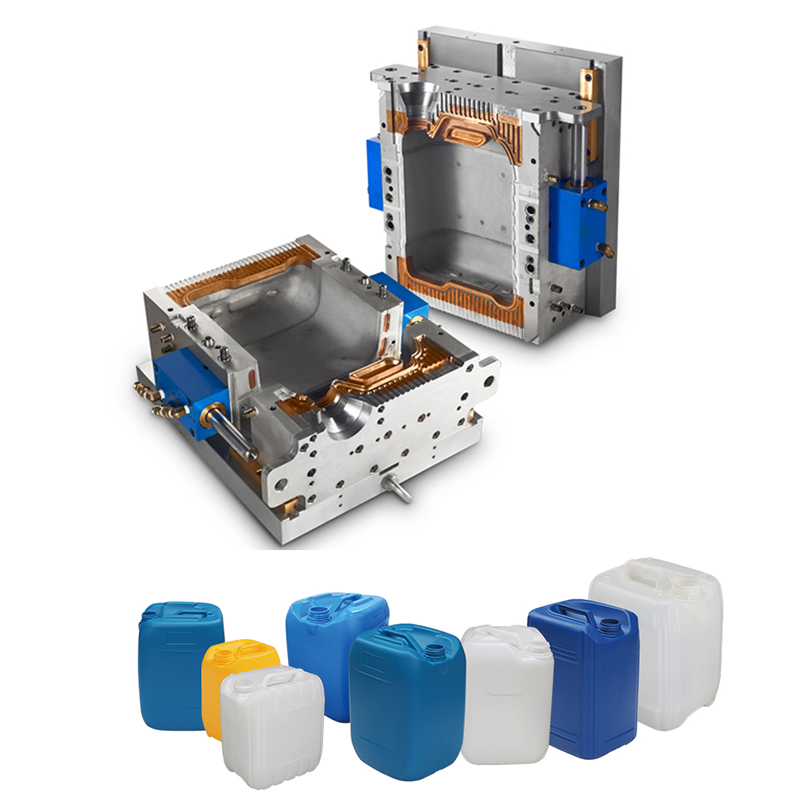

How to Customize a Plastic Injection Mould for Your Project

Customize Plastic Injection Mould Offers Innovative Solutions for CompaniesIn today's fast-paced manufacturing industry, the demand for high-quality plastic injection moulds is on the rise. Companies are constantly seeking innovative solutions to meet their specific production needs, and one company leading the way in this industry is [Company Name].[Company Name] is a leading provider of customized plastic injection moulds, catering to a wide range of industries including automotive, electronics, medical, and consumer goods. With a strong emphasis on innovation and precision engineering, the company has earned a reputation for delivering top-notch products that meet the exacting standards of its clients.The company's custom plastic injection moulds are designed to meet the unique specifications of each client, ensuring that the final product meets their requirements with precision and accuracy. Whether it's a complex design for a medical device or a high-precision component for an automotive application, [Company Name] has the expertise to deliver exceptional results.With a team of highly skilled engineers and designers, [Company Name] works closely with its clients to understand their specific needs and develop custom solutions that meet and exceed expectations. The company's state-of-the-art manufacturing facility is equipped with the latest technology and machinery, allowing for the production of high-quality moulds with fast turnaround times.One of the key factors that sets [Company Name] apart from its competitors is its commitment to quality. The company adheres to strict quality control measures at every stage of the manufacturing process, ensuring that each mould meets the highest standards of performance and durability. This dedication to quality has earned [Company Name] the trust and loyalty of its clients, who rely on the company to deliver reliable and consistent results.In addition to its focus on quality, [Company Name] is also dedicated to sustainability and environmental responsibility. The company uses eco-friendly materials and processes in its manufacturing operations, minimizing its impact on the environment while delivering products that are safe and reliable.Furthermore, [Company Name] continuously invests in research and development to stay at the forefront of technological advancements in the industry. This proactive approach allows the company to offer cutting-edge solutions to its clients, ensuring that they have access to the latest innovations in plastic injection mould technology.As the demand for customized plastic injection moulds continues to grow, [Company Name] is well-positioned to meet the needs of companies across various industries. With its unwavering commitment to quality, innovation, and customer satisfaction, the company is poised to remain a leader in the plastic injection mould industry for years to come.In conclusion, [Company Name] is a trusted partner for companies seeking customized plastic injection moulds that are tailored to their specific needs. With a focus on quality, innovation, and customer satisfaction, the company continues to deliver exceptional results that meet the exacting standards of its clients. As the industry evolves, [Company Name] remains at the forefront, offering cutting-edge solutions that address the ever-changing needs of the manufacturing sector.

New Injection Stretch Blow Molding Machine Offers One-Step Solution

One Step Injection Stretch Blow Molding Machine Technology revolutionizes the manufacturing process in the packaging industry. The {Company Name} is at the forefront of this advancement, utilizing this cutting-edge technology to enhance production efficiency and produce high-quality plastic containers.The one-step injection stretch blow molding (ISBM) process integrates the injection molding and blow molding processes into a single machine, streamlining the production of plastic bottles and containers. This innovative technology eliminates the need for intermediate steps, resulting in faster production times, reduced energy consumption, and lower manufacturing costs.The {Company Name} has fully embraced this groundbreaking technology, investing in state-of-the-art ISBM machines to meet the growing demand for plastic packaging solutions. By incorporating the one-step ISBM process into their production line, the company has strengthened its position as a leading provider of plastic containers for various industries, including food and beverage, pharmaceuticals, personal care, and more.With its advanced features and capabilities, the one-step ISBM machine enables the {Company Name} to produce a wide range of plastic containers with exceptional precision and consistency. The technology allows for greater design flexibility, enabling the company to create custom containers that meet specific customer requirements. Additionally, the ISBM process ensures that the containers meet high standards of quality and hygiene, making them suitable for a variety of products.In addition to enhancing production efficiency, the one-step ISBM technology also contributes to sustainability efforts. The process requires less energy and raw materials compared to traditional manufacturing methods, leading to reduced environmental impact. This aligns with the {Company Name}'s commitment to sustainability and responsible business practices, further reinforcing its leadership in the packaging industry.Furthermore, the integration of one-step ISBM technology into the company's operations has improved overall production capabilities. With faster cycle times and seamless automation, the {Company Name} can meet increased production demands while maintaining the highest standards of quality. This positions the company as a reliable partner for businesses seeking efficient and sustainable packaging solutions.By leveraging the capabilities of the one-step ISBM machines, the {Company Name} has expanded its product offerings to include a diverse range of plastic containers. From PET bottles for beverages to HDPE containers for healthcare products, the company can fulfill a wide spectrum of packaging needs. This versatility, combined with the technology's efficiency, enables the company to cater to various market segments and deliver exceptional solutions to its customers.Through the adoption of one-step injection stretch blow molding technology, the {Company Name} continues to raise the bar for plastic packaging manufacturing. The company's investment in this advanced technology reflects its dedication to innovation and excellence, solidifying its position as a leading player in the industry. With the ability to produce high-quality, sustainable containers at scale, the {Company Name} is well-equipped to meet the evolving needs of its customers and contribute to a more efficient and environmentally friendly packaging landscape.

New Technology Makes Plastic Jar Production Faster and More Efficient

Pet Jar Blow Moulding Machine- The Future of Plastic Jar ManufacturingPlastic jars have become a ubiquitous item in our daily lives- from storing cosmetics to food items, these jars have become a staple in all our homes and businesses. Over the years, the process of manufacturing plastic jars has evolved to become more efficient, streamlined, and environmentally friendly. The Pet Jar Blow Moulding Machine is the latest innovation in the manufacturing process of plastic jars, catering to the ever-rising demand for sustainable, high-quality plastic jars.The Pet Jar Blow Moulding Machine is a cutting-edge technology that offers a comprehensive range of benefits, ranging from faster production rates to reduced wastage and lower energy consumption. It is a versatile machine that is capable of producing a wide variety of plastic jars with exceptional precision and quality. The machine is equipped with the latest technology that makes it highly flexible and customizable, enabling manufacturers to produce plastic jars of different sizes, shapes, and specifications.Managed by a highly skilled workforce, Pet Jar Blow Moulding Machine manufacturers the best quality plastic jars for different industries like food and beverage, cosmetic, and pharmaceuticals. The machine is capable of producing PET jars of different types, including round, square, and rectangular. It is the go-to machine for businesses looking for reliable, high-quality plastic jar manufacturing services.The introduction of the Pet Jar Blow Moulding Machine has revolutionized the process of plastic jar manufacturing by making it more streamlined and cost-effective. Apart from this, it is also environmentally friendly as it consumes less energy compared to its conventional counterparts. The machine operates at a lower temperature, providing manufacturers with a more energy-efficient production process.One of the significant advantages of the Pet Jar Blow Moulding Machine is that it has a faster production rate, leading to a higher volume of production within a shorter time. With the rise in demand for plastic jars, businesses require a machine that can keep up with this demand. This is where the Pet Jar Blow Moulding Machine comes in handy, as it can produce up to 5,000 units per hour, making it an ideal machine for businesses with high production requirements.Furthermore, the Pet Jar Blow Moulding Machine focuses on producing sustainable products, thereby reducing the impact of plastic on the environment. The machine uses PET resin material, which is an environmentally friendly material that can be recycled to produce other products. Because of this, the Pet Jar Blow Moulding Machine is a sustainable solution to plastic jar manufacturing, ensuring that businesses are not only producing high-quality plastic jars but are also doing so in an environmentally responsible manner.The Pet Jar Blow Moulding Machine has several features that set it apart from its conventional counterparts. The machine has an adjustable speed mechanism, a high heating capacity, and an automated control system that allows for greater precision, consistency, and reliability. Additionally, the machine is easy to operate and maintain, making it an ideal machine for small businesses or enterprises with low technical expertise.In conclusion, the Pet Jar Blow Moulding Machine is the ideal solution for businesses looking to produce high-quality, sustainable plastic jars. The machine is ideal for businesses that require a high rate of production, minimal wastage, and lower energy consumption. With its cutting-edge technology and the ability to produce plastic jars of different sizes and shapes, the machine is the future of plastic jar manufacturing. As businesses continue to shift towards sustainability, the Pet Jar Blow Moulding Machine offers a sustainable solution to plastic jar manufacturing, thereby reducing the impact of plastic on the environment.

High-quality 4 Cavity Semi Auto Blow Molding Machine for Efficient Production

[Company Introduction] With over 20 years of experience in the manufacturing industry, our company has been dedicated to providing high-quality and innovative solutions for the packaging and manufacturing sector. We have a strong focus on research and development, constantly striving to improve and enhance our products to meet the ever-evolving needs of our customers. Our commitment to excellence has allowed us to establish ourselves as a leading provider of blow molding machines and other manufacturing equipment.In line with our dedication to innovation, we are proud to introduce our latest product, the 4 Cavity Semi Auto Blow Molding Machine. Built with precision and efficiency in mind, this machine is designed to meet the demands of modern manufacturing processes, offering a range of features that set it apart from traditional blow molding machines.[News Content]Our company is excited to announce the launch of the 4 Cavity Semi Auto Blow Molding Machine, a state-of-the-art piece of equipment that promises to revolutionize the packaging and manufacturing industry. This new machine has been meticulously designed and engineered to offer unmatched efficiency, precision, and versatility, making it the perfect choice for businesses looking to enhance their production capabilities.One of the key features of the 4 Cavity Semi Auto Blow Molding Machine is its high-speed production capabilities. With a powerful and reliable motor, this machine can produce up to 4800 bottles per hour, making it an ideal solution for businesses with high-volume production needs. This impressive production speed allows companies to significantly increase their output without compromising on quality or consistency.In addition to its speed, the 4 Cavity Semi Auto Blow Molding Machine also boasts a range of advanced technological features that ensure maximum precision and efficiency. The machine is equipped with an advanced heating system that delivers precise and uniform heating to the preform, resulting in consistently high-quality products. Moreover, the machine's intuitive control panel allows operators to easily monitor and adjust various parameters, ensuring optimal performance at all times.Furthermore, the 4 Cavity Semi Auto Blow Molding Machine is designed for versatility, capable of producing a wide range of bottle sizes and shapes. This flexibility is invaluable to businesses that require the ability to quickly adapt to changing market demands and consumer preferences. With quick and easy mold changes, the machine can seamlessly transition between different production runs, allowing businesses to remain responsive and agile in today's dynamic market.As with all of our products, the 4 Cavity Semi Auto Blow Molding Machine is built to the highest standards of quality and reliability. We understand the importance of minimizing downtime and maximizing productivity, which is why we have incorporated robust and durable components into the machine's construction. This ensures that businesses can rely on the machine to deliver consistent performance day in and day out, minimizing the risk of costly disruptions to production.In conclusion, the 4 Cavity Semi Auto Blow Molding Machine represents a significant advancement in the field of blow molding technology. Its combination of speed, precision, and versatility makes it an invaluable asset for businesses looking to enhance their production capabilities and remain competitive in today's fast-paced market. As a company committed to innovation and excellence, we are proud to bring this groundbreaking machine to the market and look forward to seeing the positive impact it will have on our customers' operations.

Discover the Latest Innovation in Plastic Bottle Blow Mould Technology

Title: Innovations in Plastic Bottle Blow Mould Technology: Enhancing Efficiency and Sustainability in PackagingIntroduction:Plastic bottles have become an essential part of our daily lives, serving as a convenient and often necessary means for packaging various products. In recent years, the market demand for plastic bottles has been growing exponentially, leading to increased focus on enhancing their production efficiency and sustainability. Invested in fulfilling these demands, a leading manufacturer in plastic bottle blow mould technology has developed a groundbreaking solution that not only enhances manufacturing efficiency but also contributes to environmental sustainability.Company Overview (remove brand name):{The company}—a pioneer in plastic bottle blow mould technology—has been a leading name in the industry for several decades. With a strong commitment to continuous innovation and cutting-edge research, the company has consistently delivered high-quality products and solutions that meet the evolving needs of diverse sectors. Known for its expertise in mould design and manufacturing, {the company} has earned a reputation for reliability, efficiency, and environmental consciousness.Innovative Plastic Bottle Blow Mould Technology:{The company} has recently unveiled its latest breakthrough in plastic bottle blow mould technology, which promises to revolutionize the packaging industry. The innovative solution encompasses several key features that address the growing demands for efficiency, durability, and sustainability.1. Enhanced Productivity:The newly developed blow mould technology incorporates advanced automation and precision engineering to streamline the manufacturing process. By optimizing the bottle extrusion and stretching process, {the company} has achieved significantly higher production rates, allowing manufacturers to produce more bottles within a specific timeframe. This increased productivity not only improves efficiency for businesses but also contributes to meeting the rising consumer demand efficiently.2. Resource Optimization:Recognizing the need for sustainable practices, {the company} has emphasized resource optimization in its new blow mould technology. By utilizing cutting-edge design techniques, the mould ensures minimum material waste during the production process. This reduces the overall carbon footprint associated with plastic bottle manufacturing. Additionally, the innovative design allows for the use of recycled plastic materials, thus promoting circular economy principles and reducing the reliance on virgin plastics.3. Enhanced Bottle Performance:The newly developed blow mould technology by {the company} focuses on improving bottle durability and performance. Through innovative design and precise control of wall thickness, the mould ensures uniform distribution of material, resulting in stronger and more robust bottles. This not only reduces the chances of deformation during transportation and storage but also enhances the overall user experience. With enhanced packaging integrity, businesses can confidently maintain product quality and reduce the risk of leaks or damages.4. Customization and Product Versatility:{The company}'s blow mould technology enables enhanced customization options for plastic bottle manufacturing. The flexible mould design facilitates the production of bottles in various shapes, sizes, and designs, catering to the diverse requirements of different industries. Whether it is cosmetics, beverages, or household chemicals, businesses can now provide unique and eye-catching packaging solutions to stand out in a competitive market.Conclusion:As the demand for plastic bottles continues to rise across industries, improving efficiency and sustainability in their production becomes imperative. {The company}'s innovative plastic bottle blow mould technology offers a significant breakthrough in addressing these challenges. By combining enhanced productivity, resource optimization, improved bottle performance, and customization options, {the company} is poised to revolutionize the packaging industry, allowing manufacturers to meet consumer demands while minimizing environmental impact. With their commitment to continuous innovation, {the company} sets a strong example for the industry, emphasizing the importance of sustainable solutions in shaping a greener future.

Explore the Latest Innovation in Pet Blow Molders for Efficient Plastic Bottle Production

Title: Innovative Pet Blow Molders Revolutionize Plastic Bottle ProductionIntroduction:In today's dynamic consumer market, the demand for sustainable packaging solutions is rapidly increasing. To address this growing need, several companies are employing innovative techniques to manufacture environmentally friendly plastic bottles. One such pioneering entity is {Company Name}. Recognized for their groundbreaking Pet Blow Molders, {Company Name} is transforming the plastic bottle production industry by introducing cutting-edge technology that improves efficiency, reduces waste, and enhances sustainability.1. Enhanced Efficiency:With the goal of meeting the rising demand for plastic bottles without compromising on quality, {Company Name} has developed state-of-the-art Pet Blow Molders. These machines utilize advanced automation technology to optimize production processes, resulting in boosted efficiency and reduced production time. By streamlining operations, {Company Name} empowers businesses to meet consumer demands promptly, facilitating the growth of the plastic packaging industry.2. Focus on Sustainability:In response to the mounting concern about plastic waste, {Company Name} has integrated sustainability measures into their Pet Blow Molders. By using PET (polyethylene terephthalate) material, a widely recyclable plastic, these machines allow for the production of bottles that can be repurposed and recycled. This ecological approach aligns with global efforts to foster a circular economy, reducing the environmental impact of plastic packaging.3. Cutting-edge Technology:A major strength of {Company Name} lies in their commitment to innovation. Their Pet Blow Molders are engineered with cutting-edge technology that ensures maximum precision and durability. These machines are capable of creating bottles in various shapes and sizes, catering to the unique requirements of different industries. Equipped with next-generation features, {Company Name}'s Pet Blow Molders are quickly becoming the go-to choice for businesses seeking top-quality plastic bottles.4. Versatile Applications:{Company Name}'s Pet Blow Molders are incredibly versatile, accommodating a wide range of industry needs. Whether it is the food and beverage sector, household products, cosmetics, or pharmaceuticals, these machines are capable of producing bottles that meet the highest quality standards across diverse industries. The adaptability of these Pet Blow Molders positions {Company Name} as a reliable partner for businesses seeking innovative packaging solutions.5. Unparalleled Customer Support:Understanding the importance of comprehensive customer support, {Company Name} offers comprehensive technical assistance to ensure optimal performance of their Pet Blow Molders. Their skilled team of professionals provides swift and efficient maintenance services, minimizing downtime and maximizing productivity. This unparalleled commitment to customer satisfaction has earned {Company Name} a reputation for reliability and trustworthiness within the industry.Closing:In conclusion, {Company Name} is revolutionizing the plastic bottle production industry with their innovative Pet Blow Molders. By combining enhanced efficiency, sustainability, cutting-edge technology, versatility, and unparalleled customer support, {Company Name} is setting new benchmarks for contemporary plastic packaging solutions. Embracing these groundbreaking machines will not only enable businesses to meet increasing consumer demands but also contribute towards a greener and more sustainable future.

Key Insights and Latest Trends in Pet Blowing Moulds Revealed

Pet Blowing Mould: Revolutionizing the Packaging IndustryIn today's fast-paced world, where convenience and efficiency are paramount, the packaging industry plays a vital role in ensuring the smooth functioning of various sectors. Among the many advancements in this field, one technology that has revolutionized the industry is Pet Blowing Mould. This cutting-edge technology has not only streamlined the manufacturing process but has also opened up new opportunities for businesses to thrive.Pet Blowing Mould, a breakthrough in the manufacturing of plastic containers, offers numerous advantages over traditional production methods. By using this technology, manufacturers can produce lightweight and durable plastic bottles and containers at a much faster rate compared to conventional techniques. As a result, this technology has become popular across a wide range of industries, including food and beverages, pharmaceuticals, cosmetics, and more.One company that has been at the forefront of developing and perfecting this technology is {}. With years of experience in the packaging industry, they have become market leaders in providing innovative solutions to their clients. Through their relentless commitment to research and development, they have successfully developed Pet Blowing Moulds that are highly efficient and deliver exceptional results.By offering state-of-the-art Pet Blowing Moulds, the company has enabled manufacturers to enhance their production capabilities significantly. These moulds are designed to optimize the blowing process, allowing for consistent and precise shaping of plastic containers. The superior quality of the moulds ensures that each product meets the highest standards of durability, strength, and aesthetic appeal.Furthermore, these Pet Blowing Moulds are customizable, catering to the specific needs and requirements of different industries. The team at {} works closely with their clients, understanding their unique challenges and goals, to provide tailored solutions. Whether it's developing moulds for a small-scale operation or a large-scale production facility, the company offers comprehensive support and expertise at every step of the process.Apart from their commitment to providing top-notch moulds, {} also places high importance on sustainability. They understand the need for eco-friendly solutions in the packaging industry, and their Pet Blowing Moulds reflect this ideology. By using advanced technology and materials, their moulds minimize waste, reduce energy consumption, and contribute to a greener future.The impact of {}'s Pet Blowing Moulds in the packaging industry has been profound. They have revolutionized the way plastic containers are manufactured, addressing the demand for cost-effective, sustainable, and high-quality products. With their cutting-edge technology and unwavering dedication to customer satisfaction, they continue to set new benchmarks for excellence in the field.As the packaging industry continues to evolve, Pet Blowing Moulds are poised to play an even more significant role. {}'s commitment to innovation and sustainability ensures that they will remain at the forefront of this transformative technology, driving progress and shaping the future of the industry.In conclusion, Pet Blowing Mould technology has brought a revolution to the packaging industry, ensuring efficient and sustainable manufacturing of plastic containers. With companies like {} leading the way in developing and providing state-of-the-art moulds, manufacturers can unlock new possibilities and meet the ever-growing consumer demands. The impact of this technology goes beyond productivity; it paves the way for a more sustainable and environmentally conscious future.

Oil bottle blow molding machine: A game changer for plastic packaging industry

Plastic Oil Bottle Blow Molding Machine Revolutionizes Production Process at {}In a bid to enhance their production process, {}, a leading manufacturer in the plastic packaging industry, has recently invested in a state-of-the-art Plastic Oil Bottle Blow Molding Machine. This cutting-edge technology is set to revolutionize the manufacturing of oil bottles, allowing the company to meet the growing demand for their products while maintaining high-quality standards.The new Plastic Oil Bottle Blow Molding Machine promises to significantly improve efficiency and productivity at {}. By modernizing their production line with this advanced equipment, the company aims to streamline their manufacturing process and reduce lead times, ultimately benefiting their customers with faster turnaround times and increased product availability.The Plastic Oil Bottle Blow Molding Machine is designed to produce a wide range of oil bottles with precision and consistency. With the ability to mold bottles of various shapes and sizes, the machine provides {} with the flexibility to cater to diverse packaging needs. This versatility allows the company to offer a comprehensive line of oil bottles, meeting the requirements of different clients and market segments.Furthermore, the new machine is equipped with innovative features that ensure the production of durable and high-quality oil bottles. Its advanced technology enables {} to uphold their commitment to delivering reliable and sustainable packaging solutions to their customers. This investment underscores the company's dedication to maintaining excellence in their products, setting them apart as a trusted leader in the industry.The integration of the Plastic Oil Bottle Blow Molding Machine into {}'s manufacturing process represents a significant step forward in their commitment to sustainability. By utilizing this state-of-the-art equipment, the company aims to minimize waste and optimize energy efficiency during the production of oil bottles. This aligns with their broader sustainability initiatives, allowing them to reduce their environmental footprint and contribute to a greener future.As a leading player in the plastic packaging industry, {}'s investment in the Plastic Oil Bottle Blow Molding Machine reaffirms their position as an innovative and forward-thinking company. The adoption of this advanced technology demonstrates their proactive approach to keeping pace with market demands and embracing industry-leading solutions to enhance their operations.With the implementation of the Plastic Oil Bottle Blow Molding Machine, {} is well-positioned to capitalize on the growing demand for oil bottles while maintaining their commitment to delivering exceptional products. This strategic move reinforces their reputation as a reliable partner for packaging solutions, further solidifying their standing in the competitive marketplace.The incorporation of the Plastic Oil Bottle Blow Molding Machine into {}'s production process is a testament to their continual pursuit of excellence and innovation. By embracing cutting-edge technology, the company is poised to elevate their manufacturing capabilities and drive further growth in the plastic packaging sector.In conclusion, the introduction of the Plastic Oil Bottle Blow Molding Machine marks a milestone in {}'s journey towards enhancing their manufacturing capabilities. This investment underscores their dedication to providing superior packaging solutions to their customers, while also demonstrating their commitment to sustainability and operational efficiency. With this innovative addition to their production line, {} is set to elevate their competitiveness and solidify their position as a leading force in the plastic packaging industry.