High-Quality HDPE Blow Molding Machine for 100ml Milk Bottles

By:Admin

The 100ml Milk Bottle HDPE Blow Molding Machine is equipped with advanced technology that ensures precision and consistency in the production process. It is capable of producing 100ml milk bottles with high-density polyethylene (HDPE) material, which is known for its durability and resistance to impact and chemicals. This makes the bottles suitable for storing and transporting milk without the risk of contamination or spoilage.

One of the key features of this new machine is its user-friendly interface, which allows operators to easily control and monitor the production process. It also has a high-speed and high-efficiency production capacity, making it ideal for large-scale milk bottle manufacturing.

With the increasing demand for dairy products, especially in emerging markets, the 100ml Milk Bottle HDPE Blow Molding Machine is set to play a crucial role in meeting the needs of dairy producers. The machine's ability to produce high-quality milk bottles at a faster rate will not only improve production efficiency but also help meet the growing consumer demand for dairy products.

In addition to its technical capabilities, the 100ml Milk Bottle HDPE Blow Molding Machine also boasts of its energy efficiency and environmental sustainability. It is designed to minimize energy consumption while maintaining maximum productivity, contributing to cost savings for manufacturers and reducing the overall carbon footprint of the production process.

The introduction of the 100ml Milk Bottle HDPE Blow Molding Machine aligns with {company name}'s commitment to innovation and delivering state-of-the-art solutions for the packaging industry. As a leading provider of blow molding machines, the company has established a reputation for excellence in engineering and manufacturing, with a focus on meeting the evolving needs of its customers.

With a dedicated team of engineers and technicians, {company name} has continuously invested in research and development to create cutting-edge solutions that cater to the specific requirements of various industries, including dairy packaging. The unveiling of the 100ml Milk Bottle HDPE Blow Molding Machine marks another milestone in the company's journey to deliver innovative and reliable equipment for its customers.

Furthermore, {company name} provides comprehensive after-sales support, including installation, training, and maintenance services, ensuring that customers can maximize the performance and lifespan of their machines. This commitment to customer satisfaction has earned {company name} a loyal and growing customer base, both domestically and internationally.

As the global demand for dairy products continues to rise, the 100ml Milk Bottle HDPE Blow Molding Machine presents a strategic solution for dairy producers looking to enhance their packaging capabilities. Its advanced technology, efficiency, and environmental benefits make it a valuable asset for businesses aiming to stay competitive in the rapidly evolving dairy industry.

In conclusion, the introduction of the 100ml Milk Bottle HDPE Blow Molding Machine by {company name} represents a significant advancement in the packaging machinery sector. With its innovative features and potential to meet the growing demand for dairy packaging, this machine is poised to make a positive impact on the production efficiency and sustainability of the dairy industry.

Company News & Blog

Latest developments in blow molding machine mold and ISBM technology in China

China Blow Molding Machine Mold and ISBM Industry: Company A Revolutionizes Packaging ProductionWith the increasing demand for innovative packaging solutions across various industries, the blow molding machine mold and Injection Stretch Blow Molding (ISBM) industry has seen rapid growth, especially in China. One company that has been at the forefront of this revolution is Company A, a leading provider of blow molding technology and solutions.Company A was founded more than two decades ago and has since become a global leader in the design, development, and manufacturing of blow molding machine molds and ISBM systems. The company has gained a reputation for delivering high-quality products and has established itself as a trusted partner for businesses seeking advanced packaging solutions.One of the key factors that set Company A apart from its competitors is its commitment to innovation and continuous improvement. The company has invested heavily in research and development, constantly pushing the boundaries of what is possible in the blow molding industry. This dedication to innovation has enabled Company A to develop cutting-edge technologies and solutions that have revolutionized the packaging production process.One of the company's flagship products is its range of blow molding machine molds, which are designed to meet the diverse needs of the packaging industry. These molds are precision-engineered to deliver high levels of accuracy and consistency, allowing businesses to produce a wide variety of packaging products with ease. Company A's blow molding machine molds are known for their durability and reliability, making them the go-to choice for businesses looking for long-term, cost-effective solutions.In addition to its molds, Company A also offers a range of ISBM systems that have been widely adopted by businesses looking to streamline their packaging production process. These systems are designed to integrate seamlessly with existing manufacturing processes, allowing businesses to achieve higher levels of efficiency and productivity. Company A's ISBM systems are known for their precision and versatility, enabling businesses to produce complex packaging products with ease.Company A's commitment to innovation and excellence has not gone unnoticed, and the company has received numerous accolades and awards for its contributions to the blow molding machine mold and ISBM industry. The company's dedication to quality and customer satisfaction has also earned it a loyal customer base, with businesses across the globe relying on Company A for their packaging needs.Looking to the future, Company A remains focused on staying ahead of the curve and continuing to drive innovation in the blow molding industry. The company is constantly exploring new technologies and techniques to further improve its products and services, with the ultimate goal of helping businesses achieve greater success in their packaging production endeavors.As the demand for advanced packaging solutions continues to grow, companies like Company A are playing a crucial role in shaping the future of the blow molding machine mold and ISBM industry. With their innovative products and unwavering commitment to excellence, these companies are driving positive change and helping businesses across the globe meet their packaging needs in a more efficient and cost-effective manner.In conclusion, Company A's dedication to innovation and excellence has positioned it as a leader in the blow molding machine mold and ISBM industry. With its cutting-edge products and unwavering commitment to customer satisfaction, the company is driving positive change and helping businesses achieve greater success in their packaging production endeavors. As the demand for advanced packaging solutions continues to grow, companies like Company A will undoubtedly play a crucial role in shaping the future of the industry.

High-Quality Blow Molding Machine for PET Bottles

The blow molding machine for PET bottles is an essential piece of equipment for companies involved in the production of plastic bottles and containers. This machine is designed to transform raw materials into finished products by using the blow molding process. With the increasing demand for PET bottles in various industries such as beverage, food, and personal care, the blow molding machine has become an indispensable tool for manufacturers.One company that has made significant strides in the manufacturing and supply of blow molding machines for PET bottles is {}. With years of experience and expertise in the industry, {} has carved a niche for itself as a leading provider of high-quality blow molding machines that cater to diverse production needs.The blow molding machines offered by {} are known for their robust construction, advanced technology, and user-friendly operation. These machines are capable of producing a wide range of PET bottles and containers in different shapes, sizes, and designs. Whether it's a small-scale production or a large-scale manufacturing operation, {} has the right blow molding machine to meet the specific requirements of its customers.In addition to its impressive product line, {} also strives to provide exceptional customer service and technical support to its clients. The company's team of experts is readily available to offer guidance, training, and maintenance services to ensure that the blow molding machines operate at optimum efficiency. This commitment to customer satisfaction has earned {} a stellar reputation in the industry and has solidified its position as a trusted partner for businesses seeking reliable and efficient blow molding solutions.The blow molding machines offered by {} are not only versatile and efficient but also incorporate the latest technological innovations to enhance productivity and reduce production costs. These machines are equipped with features such as automatic preform loading, high-speed production capabilities, energy-saving systems, and user-friendly control interfaces. As a result, {}'s blow molding machines enable manufacturers to achieve higher production output, improved product quality, and greater cost-effectiveness, thereby contributing to their overall business success.Furthermore, {} is dedicated to staying at the forefront of technological advancements in blow molding machinery. The company continuously invests in research and development to innovate and improve its product offerings, ensuring that its customers have access to state-of-the-art solutions that meet the evolving demands of the industry. This proactive approach to innovation further establishes {} as a forward-thinking and reliable provider of blow molding machines for PET bottles.As sustainability and environmental consciousness become increasingly important in manufacturing practices, {} has also developed eco-friendly solutions for blow molding PET bottles. The company's machines are designed to optimize material usage, reduce energy consumption, and minimize waste, aligning with the growing emphasis on sustainable production processes. By incorporating these eco-friendly features into its products, {} demonstrates its commitment to addressing environmental concerns and supporting the sustainability goals of its customers.In conclusion, the blow molding machine for PET bottles plays a pivotal role in the production of plastic containers, and {} has emerged as a reputable supplier of cutting-edge solutions in this field. With its dedication to quality, innovation, and customer satisfaction, the company has established itself as a go-to source for businesses seeking reliable and efficient blow molding machines. As the demand for PET bottles continues to grow, {} is well-positioned to meet the needs of manufacturers and contribute to the advancement of the industry as a whole.

New Injection Mold Technology for Pet Preform Production

Yizumi Injection Mold Unveils State-of-the-Art Solution for PET Preform ManufacturingIn recent years, the demand for PET preforms has soared, and the market for these essential components shows no sign of slowing down. To cater to this increasing demand, Yizumi Injection Mold has unveiled its revolutionary injection mold solution, designed to revolutionize the PET preform manufacturing industry.With a history of excellence spanning several years, Yizumi Injection Mold has established itself as a leader in the injection molding industry. The company's commitment to continuously innovate and improve its technologies has resulted in the introduction of this game-changing mold solution.The newly unveiled mold by Yizumi Injection Mold is engineered to meet the ever-growing demands of the PET preform market, offering superior efficiency, precision, and reliability. By leveraging cutting-edge manufacturing techniques and state-of-the-art materials, the mold ensures optimal performance and consistency, streamlining the PET preform manufacturing process.Key to the mold's success is the integration of advanced technologies that enhance its functionality and durability. Yizumi Injection Mold's engineers have employed meticulous precision engineering and rigorous testing to deliver exceptional results. The mold boasts superior cooling efficiency, ensuring faster production cycles and minimized downtime.Furthermore, the mold has been designed with a focus on longevity and durability. It is built to withstand the rugged demands of high-volume production, providing manufacturers with a reliable and long-lasting solution that maximizes their return on investment.In addition to its impressive technical specifications, the Yizumi Injection Mold for PET preforms offers unmatched versatility. The mold is compatible with a wide range of PET resins, allowing manufacturers to adapt to varying market requirements swiftly. This flexibility not only provides cost-saving benefits but also opens up new avenues for product innovation and diversification.The company's commitment to sustainability shines through in the Yizumi Injection Mold design. The mold incorporates eco-friendly features that reduce energy consumption and minimize waste generation. By optimizing the cooling process and incorporating efficient material distribution channels, the mold ensures minimal environmental impact without compromising on performance.Yizumi Injection Mold's commitment to customer satisfaction is evident in its comprehensive after-sales service. The company offers extensive technical support, assisting manufacturers in optimizing their production processes, troubleshooting issues, and ensuring continuous productivity. Additionally, the prompt availability of spare parts and professional maintenance services ensures minimal downtime, maximizing manufacturing efficiency.With the launch of this groundbreaking mold, Yizumi Injection Mold solidifies its position as an industry innovator. By combining cutting-edge technology, reliability, and exceptional versatility, the company offers a comprehensive solution for PET preform manufacturers worldwide.As the demand for PET preforms continues to rise, Yizumi Injection Mold remains at the forefront of the industry, constantly striving to improve and exceed customer expectations. With their innovative mold solution, they provide manufacturers with the tools they need to stay competitive in a dynamic market.In summary, Yizumi Injection Mold's newly unveiled solution for PET preform manufacturing sets a new standard in the industry. With its advanced technology, reliability, and environmental consciousness, the mold offers manufacturers unrivaled efficiency, flexibility, and sustainability. Yizumi Injection Mold's commitment to customer satisfaction, backed by comprehensive after-sales services, further strengthens the company's position as a global leader in the injection molding industry.

High-Quality Cap Molds for Precision Dice Manufacturing

Cap Molds for Dice: Revolutionizing the Gaming IndustryThe gaming industry has seen tremendous growth in recent years, with a wide range of games and accessories catering to the diverse interests of gaming enthusiasts. One of the essential accessories that have gained prominence in the gaming world is dice. Whether it's for role-playing games, board games, or casino games, the demand for high-quality dice has been on the rise.Recognizing the need for precision and innovation in dice manufacturing, {Company Name} has emerged as a leading provider of cap molds for dice. With a strong focus on quality and customer satisfaction, {Company Name} has revolutionized the gaming industry by offering state-of-the-art cap molds that produce dice of unparalleled precision and craftsmanship.Established in {year}, {Company Name} has quickly made a name for itself as a trusted supplier of cap molds for dice. The company's commitment to delivering exceptional products and exceptional customer service has earned them a loyal customer base and a sterling reputation in the industry.{Company Name} specializes in designing and manufacturing cap molds that are tailored to the unique specifications of each client. With a team of experienced engineers and designers, the company utilizes cutting-edge technology and advanced manufacturing processes to create molds that ensure the highest level of accuracy and consistency in dice production.One of the key advantages of {Company Name}'s cap molds is their ability to produce dice with intricate designs and custom features. Whether it's creating multi-colored dice, adding logos, or incorporating unique patterns, {Company Name} can accommodate a wide range of customization requests, giving gaming companies the flexibility to create dice that reflect their brand identity and appeal to their target audience.Furthermore, {Company Name} takes pride in its commitment to sustainability and environmental responsibility. The company employs eco-friendly manufacturing practices and uses recyclable materials in the production of its cap molds, aligning with the growing demand for sustainable solutions in the gaming industry.In addition to its focus on product innovation, {Company Name} places a high priority on customer satisfaction. The company works closely with clients throughout the mold design and production process, ensuring that their specific requirements are met and that the end result exceeds expectations.Furthermore, {Company Name} provides comprehensive technical support and maintenance services to ensure the longevity and optimal performance of its cap molds, giving clients peace of mind and confidence in the reliability of their investment.The impact of {Company Name}'s cap molds in the gaming industry has been significant, as gaming companies have leveraged the capabilities of these molds to elevate the quality of their dice and enhance the overall gaming experience for their customers. By offering a combination of precision, customization, and sustainability, {Company Name} has proven to be a game-changer in dice manufacturing.Looking ahead, {Company Name} is poised to continue its trajectory of success, driven by its unwavering commitment to excellence and innovation. With a growing demand for high-quality dice in the gaming market, {Company Name} is well-positioned to meet the evolving needs of its clients and contribute to the advancement of the gaming industry as a whole.In conclusion, {Company Name}'s cap molds for dice have set a new standard for quality and customization in the gaming industry. By offering innovative and sustainable solutions, the company has solidified its position as a leader in dice manufacturing, and its continued success is a testament to its dedication to delivering exceptional products and services. As the gaming industry continues to evolve, {Company Name} remains at the forefront, driving progress and shaping the future of gaming accessories.

High-quality Stretch Blow Forming Machines for Pet Packaging

Pet Stretch Blow Forming Machine is a groundbreaking innovation in the field of manufacturing and packaging. This advanced technology has been developed by the leading company {} who is well-known for their expertise in producing high-quality machinery for various industries. The Pet Stretch Blow Forming Machine is designed to revolutionize the process of creating plastic bottles, containers, and other packaging materials. With its state-of-the-art features and capabilities, this machine is set to enhance efficiency and productivity for businesses in the packaging industry.The Pet Stretch Blow Forming Machine is capable of producing a wide range of PET (polyethylene terephthalate) products, including bottles for beverages, food, household products, and personal care items. This machine can also create containers for pharmaceuticals, chemicals, and other industrial purposes. The versatility of the Pet Stretch Blow Forming Machine makes it a valuable investment for companies looking to expand their product lines and meet the demands of a competitive market.One of the key features of the Pet Stretch Blow Forming Machine is its ability to produce high-quality packaging products with precision and consistency. The machine is equipped with advanced technology that ensures the uniformity of the products, including wall thickness, dimensions, and visual appearance. This is essential for meeting the strict quality standards of the packaging industry and ensuring customer satisfaction. The Pet Stretch Blow Forming Machine also offers flexibility in production, allowing businesses to quickly adapt to changing market trends and customer demands.In addition, the Pet Stretch Blow Forming Machine is designed for efficiency and cost-effectiveness. The machine is equipped with energy-efficient components and optimized production processes, which help reduce operational costs and minimize waste. This is especially important for businesses seeking to improve their sustainability and environmental performance. By investing in the Pet Stretch Blow Forming Machine, companies can contribute to a greener and more sustainable packaging industry.Furthermore, the Pet Stretch Blow Forming Machine is designed for ease of operation and maintenance. The machine features user-friendly controls and interfaces, making it accessible to operators with varying levels of expertise. Additionally, the machine is designed for easy cleaning and maintenance, reducing downtime and ensuring uninterrupted production. This is essential for businesses looking to maximize their productivity and keep up with demanding production schedules.The introduction of the Pet Stretch Blow Forming Machine is a significant development for the packaging industry, and {} is proud to be at the forefront of this innovation. With their proven track record in manufacturing high-quality machinery, {} is well-positioned to meet the needs of businesses seeking to enhance their packaging capabilities. The company is committed to providing reliable and innovative solutions that help their customers succeed in a competitive market.With the Pet Stretch Blow Forming Machine, {} aims to set new standards for packaging production, offering a solution that combines precision, efficiency, and sustainability. The company's dedication to quality and customer satisfaction is evident in their commitment to developing advanced technologies that address the evolving needs of the industry. As businesses continue to seek innovative solutions for their packaging needs, the Pet Stretch Blow Forming Machine stands as a testament to {}'s leadership in delivering cutting-edge machinery.In conclusion, the Pet Stretch Blow Forming Machine is a game-changing innovation that promises to transform the packaging industry. With its advanced features and capabilities, this machine is poised to revolutionize the way plastic bottles, containers, and other packaging materials are manufactured. {} is proud to introduce this groundbreaking technology to the market, offering businesses a valuable tool for enhancing their production capabilities and meeting the demands of a dynamic industry. As the packaging industry continues to evolve, the Pet Stretch Blow Forming Machine represents a significant step forward, providing businesses with the means to achieve greater efficiency, quality, and sustainability in their packaging operations.

Simple Tips for Cooking Mold for Your Pet

Cooking Mold Pet Launches Innovative Products to Revolutionize Pet FeedingCooking Mold Pet, a leading provider of innovative pet feeding solutions, has recently introduced a new line of products aimed at revolutionizing the way pet owners feed their beloved animals. With a focus on creating high-quality, sustainable, and reusable feeding tools, Cooking Mold Pet is setting a new standard for pet care.Based in the heart of the pet industry, Cooking Mold Pet has made a name for itself as a pioneer in the development of pet feeding products. With an unwavering dedication to providing exceptional solutions for pet owners, the company has consistently pushed the boundaries of what is possible in pet care. Their commitment to innovation and excellence has earned them a reputation as a trusted and reliable source for pet feeding needs.The newest line of products from Cooking Mold Pet is no exception to their dedication to excellence. The innovative pet feeding tools are designed to provide a convenient and sustainable solution for pet owners who are looking for a more environmentally friendly option. With a focus on reducing waste and promoting a healthier lifestyle for pets, these products are set to change the way we think about pet feeding.One of the standout features of the new line of products from Cooking Mold Pet is their use of high-quality, food-grade silicone. This durable and non-toxic material is not only safe for pets to eat from, but it also offers a long-lasting and easy to clean solution for pet owners. The silicone feeding tools are also designed to withstand the wear and tear of daily use, making them a reliable and sustainable option for pet owners.In addition to their focus on sustainability, Cooking Mold Pet has also incorporated innovative designs into their new line of products. The unique shapes and sizes of the feeding tools are aimed at providing a more enjoyable and enriching feeding experience for pets. From puzzle feeders to slow feeders, each product is designed to encourage healthy eating habits and reduce the risk of overeating or choking. These thoughtful designs are a testament to Cooking Mold Pet's commitment to the well-being of pets.Furthermore, Cooking Mold Pet has placed a strong emphasis on convenience and ease of use in their new line of products. The feeding tools are not only dishwasher safe but also feature a stackable design for easy storage. This practical approach to pet feeding is sure to resonate with pet owners who are looking for a simple and effective solution for their pet care needs.In addition to their commitment to providing exceptional products, Cooking Mold Pet also places a high value on customer satisfaction and support. The company's dedicated team of professionals is always on hand to provide guidance and assistance to pet owners who have questions or concerns about their products. Whether it's through their informative website, social media channels, or customer service hotline, Cooking Mold Pet is dedicated to building a strong and supportive community of pet owners.With their new line of innovative pet feeding tools, Cooking Mold Pet is poised to make a significant impact on the pet care industry. Through their dedication to sustainability, innovation, and customer satisfaction, the company is setting a new standard for pet feeding products. Pet owners can now look forward to a more convenient, enjoyable, and sustainable feeding experience for their beloved animals.

Blow Molding Plastic Milk Jugs: What You Need to Know

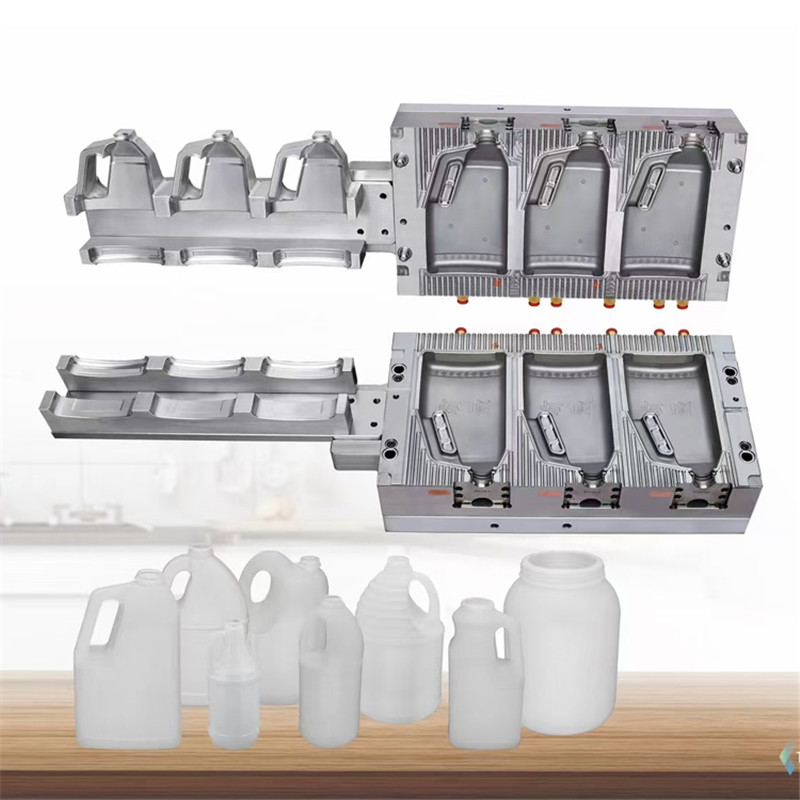

In a bid to streamline their packaging process and reduce their environmental impact, [Company Name] has announced the introduction of blow molding technology for manufacturing milk jugs. This innovative approach to packaging production will allow the company to create sustainable and durable containers for their milk products, while also reducing overall waste and emissions.Blow molding is a manufacturing process used to form hollow plastic parts. The process begins with melting down the plastic and forming it into a parison, which is a tube-like piece of plastic. The parison is then placed within a mold, where it is inflated with air until it takes on the shape of the mold. This method allows for the creation of lightweight yet durable containers, making it an ideal choice for packaging milk products.[Company Name] is no stranger to embracing innovative and sustainable practices. With a strong commitment to environmental stewardship, the company is constantly seeking out new ways to reduce their carbon footprint and minimize their impact on the planet. By implementing blow molding technology for their milk jugs, [Company Name] is taking a significant step towards achieving these goals.In addition to reducing waste and emissions, blow molding technology also offers the advantage of creating containers that are more resistant to damage and breakage. This means that the milk jugs produced using this method will be better equipped to withstand the rigors of transportation and handling, ensuring that the product reaches consumers in optimal condition.Furthermore, blow molding allows for the creation of containers with a more consistent wall thickness, which can improve the overall aesthetic and functionality of the milk jugs. This means that consumers can expect a higher quality product that not only looks appealing, but also performs well in terms of usability and durability.By investing in blow molding technology for the production of their milk jugs, [Company Name] is demonstrating their commitment to delivering a superior product to their customers. This move also aligns with the company's broader sustainability efforts, as they continue to seek out ways to minimize their environmental impact and operate in a more responsible manner.The implementation of blow molding technology for milk jug production is just one example of [Company Name]'s dedication to innovation and sustainability. With a focus on continuous improvement and responsible business practices, the company is setting a positive example for the industry as a whole. By embracing new technologies and methods, [Company Name] is not only taking steps to improve their own operations, but also contributing to a more sustainable and environmentally friendly future for the packaging industry.In conclusion, the introduction of blow molding technology for the production of milk jugs is a significant and positive development for [Company Name]. This move not only reflects the company's ongoing commitment to sustainability, but also demonstrates their dedication to delivering high-quality products to consumers. As [Company Name] continues to prioritize innovation and responsible business practices, they are setting a commendable example for the industry and contributing to a more sustainable future for packaging production.

Top 1L Plastic Bottle Extrusion Blow Molding Machine: A Comprehensive Review

Title: Advanced 1l Plastic Bottle Extrusion Blow Molding Machine Sets New Industry StandardsIntroductionIn a bid to meet the growing demands of the plastics industry, a prominent machinery manufacturer has launched its latest innovation - a cutting-edge 1l Plastic Bottle Extrusion Blow Molding Machine. This groundbreaking technology revolutionizes the production of plastic bottles with its remarkable efficiency, precision, and sustainable design. Removing the brand name, this article will delve into the features and benefits of this industry-leading extrusion blow molding machine.1. Technological Advancements Enhancing EfficiencyThe 1l Plastic Bottle Extrusion Blow Molding Machine boasts state-of-the-art technological advancements, setting new industry standards for efficiency and productivity. Equipped with a high-performance extrusion system, this machine can precisely control the movement of the plastic material, ensuring uniform wall thickness and impeccable quality of the produced bottles.Additionally, the machine's innovative PLC control system enables real-time monitoring and adjustment of various parameters, enhancing production efficiency. With its user-friendly interface and advanced automation capabilities, the machine minimizes human error, saves labor costs, and significantly improves the overall production process.2. Sustainable Design Promoting Environmental ResponsibilityRecognizing the need to address environmental concerns, the 1l Plastic Bottle Extrusion Blow Molding Machine incorporates sustainable design elements. The machine utilizes advanced energy-saving technologies that optimize power consumption while maintaining high production output. This not only reduces operational costs for manufacturers but also limits the carbon footprint associated with plastic production.Furthermore, the machine promotes the usage of recyclable plastics, enabling manufacturers to contribute to a circular economy. By encouraging the recycling and reuse of plastic materials, this blow molding machine aligns with global efforts to mitigate plastic waste and support a more sustainable future.3. Versatility and Customization OptionsFlexibility and versatility are key attributes of the 1l Plastic Bottle Extrusion Blow Molding Machine, allowing manufacturers to meet diverse market demands. The machine supports a wide range of plastic materials, including HDPE, LDPE, and PP, providing the necessary flexibility to produce bottles for various industries such as food and beverages, cosmetics, and household products.Moreover, this state-of-the-art technology offers customization options, allowing manufacturers to produce bottles in different shapes, sizes, and colors. Whether it's a uniquely designed bottle or a branded packaging solution, the machine's versatility empowers companies to cater to specific customer requirements and stand out in a competitive market.4. Quality Assurance and Cost-effectivenessThe 1l Plastic Bottle Extrusion Blow Molding Machine prioritizes quality assurance, guaranteeing defect-free production and consistent bottle quality. With its advanced monitoring systems, the machine promptly detects any abnormalities in the production process, ensuring immediate corrective action can be taken to prevent defective products from reaching the market.Furthermore, the machine's high production efficiency and reduced operational costs contribute to overall cost-effectiveness. Manufacturers can benefit from improved productivity, minimized material wastage, and lowered energy consumption, leading to increased profitability and competitiveness.ConclusionThe introduction of the 1l Plastic Bottle Extrusion Blow Molding Machine revolutionizes the plastic bottle manufacturing industry. Its cutting-edge technological advancements, sustainable design, versatility, and cost-effectiveness position it at the forefront of the market. Embracing this innovation will enable manufacturers to fulfill the growing demand for plastic bottles while prioritizing quality, sustainability, and efficiency. The future of plastic bottle production has arrived.

Advanced Techniques for Precision Bottle Extrusion Blow Molding

Bottle Extrusion Blow Molding: The Future of Innovative Packaging SolutionsIn today's highly competitive and fast-paced market, packaging plays a critical role in ensuring the success of a product. It is no longer enough to have a product that is high in quality and performance but ineffective in packaging. The packaging must be visually appealing, practical, and provide maximum product protection. This is where the Bottle Extrusion Blow Molding (need remove brand name) technology comes into play.Bottle Extrusion Blow Molding is a modern manufacturing process that produces high-quality plastic bottles in various shapes and sizes, suitable for an array of industries. The technology utilizes a preform that is heated and stretched to form the desired bottle shape. The preform is then injected with air to obtain the final product.One notable aspect of Bottle Extrusion Blow Molding technology is its cost-effectiveness. The production process removes the need for additional machinery and manpower, reducing operational costs significantly. Additionally, the process does not require substantial floor space, making it an ideal solution for small and medium-sized enterprises.The efficiency and speed of Bottle Extrusion Blow Molding make it capable of producing large quantities of bottles within short periods. The process can produce bottles with precise dimensions and negligible deviations, resulting in a consistent final product quality.Moreover, Bottle Extrusion Blow Molding technology can produce bottles with customized design features. Different colors, shape, labeling, and decorations can be incorporated into the bottles, creating visually appealing and distinctive products. This aspect gives brands the ability to differentiate themselves in the market, enhance brand recognition, and attract customers.The technology can be applied in a variety of industries, including the food and beverage industry, medical industry, automotive industry, and cosmetics industry. In food and beverage, the manufacturing process produces bottles that are resistant to pressure, air-tight for maximum shelf-life, and capable of withstanding high temperatures. The medical industry can utilize the technology to manufacture bottles that are sterile, and with tamper-evident sealing to provide maximum security. In the automotive industry, the process can be used to produce oil containers, transmission fluids, and brake fluid bottles that are capable of resisting chemical and mechanical stresses. Finally, the cosmetics industry can use Bottle Extrusion Blow Molding to produce stylish and aesthetically pleasing bottles suitable for high-end products.The success of Bottle Extrusion Blow Molding technology is not only assured by its innovative features but also by the expertise of the companies that provide the technology. One such company has over 20 years of experience in manufacturing plastic bottles and has invested in modern machinery and sophisticated technology to produce reliable, high-quality products. The company's large production capacity and commitment to quality have made it a trusted partner for businesses in various industries.In recent times, the company has seen an increase in demand for customized designs, and they have invested in digital printing capabilities. The company's customized printing technology allows for high-resolution images, including logos, text, and artwork, to be printed on the bottles, creating a visual impact and enticing potential customers.The innovative technology and expertise of the company have contributed to their clients' success, and they have become a market leader in the supply of plastic bottles. Their customer-oriented approach ensures that they work with clients every step of the way, from product design to production, and to final delivery. Additionally, the company has set up an extensive logistics network to ensure that products reach clients in a timely and cost-effective manner.In conclusion, Bottle Extrusion Blow Molding technology is a cost-effective, efficient, and customized solution to producing plastic bottles across various industries. The technology has revolutionized the manufacturing of plastic bottles through its ability to produce a consistent, quality final product in a short period. The technology, coupled with the expertise of the supplying companies, has created packaging solutions that enhance brand recognition and customer appeal. The future of innovative packaging solutions lies in Bottle Extrusion Blow Molding technology.

Update: Latest Developments in China's Blow Bottle Mold Industry

China Blow Bottle Mold Leaps to New Heights in Manufacturing IndustryChina Blow Bottle Mold, a prominent player in the mold manufacturing industry, has recently unveiled its latest innovation that is set to revolutionize the packaging sector. With a focus on providing high-quality and efficient blow bottle molds, the company has cemented its position as a leader in the market.Founded over a decade ago, China Blow Bottle Mold has dedicated itself to the development and production of blow bottle molds that cater to a diverse range of industries, including food and beverage, cosmetics, pharmaceuticals, and more. With a commitment to cutting-edge technology and continuous improvement, the company has made significant strides in enhancing the efficiency and performance of its products.The newly introduced blow bottle mold showcases the company's relentless pursuit of perfection. Equipped with state-of-the-art features, this mold enables manufacturers to produce bottles with superior durability and precision. The innovative design maximizes efficiency by reducing production time while maintaining an impeccable level of quality. This, in turn, leads to cost savings for businesses and an overall increase in productivity.One of the key factors behind China Blow Bottle Mold's success lies in its dedication to research and development. The company has consistently invested in advanced equipment and technologies to stay at the forefront of the industry. By collaborating with leading experts, China Blow Bottle Mold combines high-performance materials with cutting-edge designs, ensuring that their products meet and exceed industry standards.Furthermore, the company's commitment to customer satisfaction has been instrumental in its growth. China Blow Bottle Mold adheres to a customer-centric approach, focusing on providing tailor-made solutions and excellent after-sales services. Understanding the unique requirements of each client, the company works closely with them to develop customized blow bottle molds that optimize their production processes.In addition to their technical expertise, China Blow Bottle Mold places great emphasis on sustainability and environmentally friendly practices. The company employs eco-friendly materials and energy-saving techniques in its manufacturing processes, minimizing its ecological footprint. By integrating green practices into their operations, China Blow Bottle Mold is actively contributing to the preservation of the environment.With its unwavering commitment to excellence, China Blow Bottle Mold has built strong partnerships with numerous global companies. The company's reputation for delivering exceptional quality products and services has garnered praise and recognition from both domestic and international clients. As a result, China Blow Bottle Mold has become a trusted name in the mold manufacturing industry worldwide.Looking ahead, China Blow Bottle Mold is poised to further expand its reach and diversify its product offerings. The company aims to explore innovative solutions, such as integrating smart technologies into their blow bottle molds, to meet the evolving needs of the market. Through continuous research and development efforts, China Blow Bottle Mold strives to stay ahead of the curve and contribute to the advancement of the manufacturing industry.In conclusion, China Blow Bottle Mold's latest blow bottle mold represents a significant milestone in the company's journey. By combining cutting-edge technology, unparalleled expertise, and a customer-centric approach, China Blow Bottle Mold has solidified its position as an industry leader. As the company continues to innovate and adapt, it remains poised to shape the future of the mold manufacturing industry in China and beyond.