High-Quality Blow Mold for 5 Gallon Bottles: A Complete Guide

By:Admin

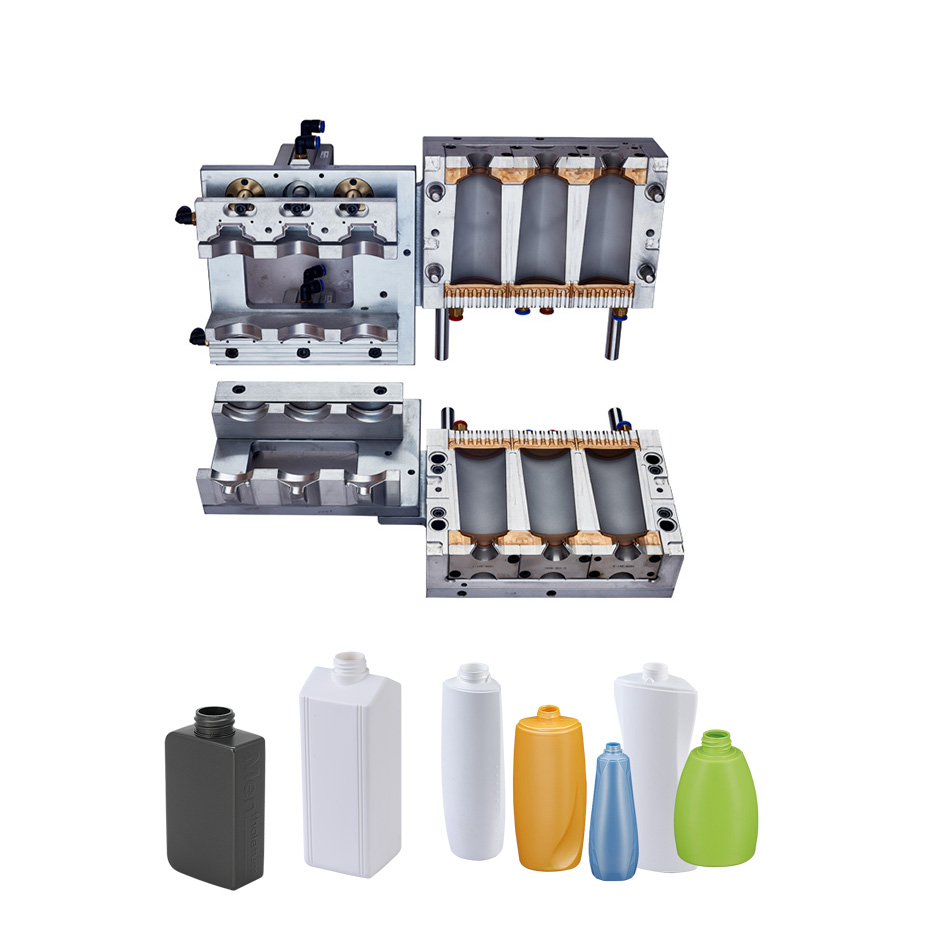

The new blow mold, developed by Manufacturer X's team of experienced engineers and designers, features advanced technology that allows for the seamless production of high-quality 5-gallon bottles. With a focus on precision and durability, the blow mold is designed to meet the demands of modern production processes, ensuring that businesses can meet their production targets without compromising on quality.

"We are thrilled to introduce our new blow mold for 5-gallon bottles," said a spokesperson for Manufacturer X. "With the increasing demand for large capacity bottles in the beverage and water industries, we recognized the need for a more efficient and reliable production solution. Our new blow mold is the result of extensive research and development, and we are confident that it will provide our customers with a competitive edge in the market."

In addition to its innovative design, the new blow mold is also engineered for ease of use and maintenance. This means that businesses can streamline their production processes and reduce downtime, ultimately leading to cost savings and improved profitability. Furthermore, Manufacturer X has ensured that the blow mold is compatible with a wide range of plastics, giving businesses the flexibility to choose the materials that best suit their specific requirements.

Manufacturer X has built a strong reputation for delivering high-quality products and exceptional customer service. With a commitment to excellence and innovation, the company has become a trusted partner for businesses seeking reliable plastics manufacturing solutions. The launch of the new blow mold for 5-gallon bottles is yet another example of Manufacturer X's dedication to meeting the evolving needs of its customers.

"We take pride in our ability to understand and anticipate the needs of the industries we serve," the spokesperson added. "The development of our new blow mold is a testament to our ongoing efforts to provide cutting-edge solutions that enable our customers to thrive in a competitive market. We are confident that this new offering will deliver exceptional value to businesses looking to enhance their production capabilities."

As Manufacturer X continues to expand its product portfolio, the company remains focused on driving innovation and delivering superior quality to its customers. With a commitment to sustainability and responsible manufacturing practices, Manufacturer X is poised to lead the way in the plastics manufacturing industry, setting new standards for excellence and reliability.

In conclusion, the launch of the new blow mold for 5-gallon bottles represents a significant milestone for Manufacturer X. With its advanced technology, user-friendly design, and compatibility with various plastics, the blow mold is set to empower businesses in the beverage and water industries to enhance their production capabilities and compete more effectively in the market. As Manufacturer X continues to push the boundaries of plastics manufacturing, the company is well-positioned to shape the future of the industry and deliver value to its customers for years to come.

Company News & Blog

Learn About Injection Stretch Blow Molding Machines and Their Uses

Injection Stretch Blow Molding Machine, a cutting-edge technology in the plastic manufacturing industry, has been revolutionizing the production process for plastic containers. This machine has the ability to produce high-quality plastic bottles in a more efficient and cost-effective manner.Injection Stretch Blow Molding Machine works by injecting molten plastic into a mold to create a preform, which is then stretched and blown into the desired shape of the bottle. This process ensures that the bottles are uniform in size, shape, and thickness, resulting in a high-quality end product. Additionally, this machine has the capability to produce bottles with intricate designs and details, making it a versatile and valuable asset for plastic manufacturers.One company that has been leveraging the benefits of Injection Stretch Blow Molding Machine is {}. Founded in {}, the company has been a leading manufacturer of plastic packaging solutions for a wide range of industries, including food and beverage, pharmaceuticals, personal care, and more. With a strong emphasis on innovation and quality, {} has continuously invested in state-of-the-art technology to meet the evolving needs of its customers.The decision to invest in Injection Stretch Blow Molding Machine has been a strategic one for {}. By integrating this advanced technology into their production process, they have been able to enhance their manufacturing capabilities and offer a wider range of packaging solutions to their customers. This has ultimately positioned {} as a key player in the plastic packaging industry, with a reputation for delivering high-quality products with efficiency and precision.One of the major advantages of Injection Stretch Blow Molding Machine is its ability to streamline the production process. With this machine, {} has been able to significantly reduce the manufacturing lead time for their plastic bottles, allowing them to meet tight deadlines and respond to market demands more effectively. This has also translated into cost savings for the company, as the efficiency of the machine has led to lower production costs and improved profitability.Furthermore, Injection Stretch Blow Molding Machine has enabled {} to expand their product offerings and cater to a diverse range of packaging needs. From standard bottles to customized designs, this machine has given {} the flexibility to produce a variety of plastic containers to meet the specific requirements of their customers. This has not only boosted their competitive advantage but has also strengthened their position as a preferred supplier in the industry.The implementation of Injection Stretch Blow Molding Machine has also had a positive impact on the overall quality of {}'s products. With the precise and consistent production capabilities of this machine, the company has been able to deliver bottles that meet the highest standards of durability, functionality, and aesthetics. This has resulted in enhanced customer satisfaction and loyalty, as {} continues to be a trusted partner for quality plastic packaging solutions.Looking ahead, {} remains committed to leveraging the technology of Injection Stretch Blow Molding Machine to drive their growth and innovation. With a focus on continuous improvement and advancement, the company is dedicated to exploring new possibilities and pushing the boundaries of plastic manufacturing. By staying at the forefront of technology, {} is poised to maintain its leadership position in the industry and meet the evolving needs of the market.In conclusion, Injection Stretch Blow Molding Machine has been a game-changer for {} in the plastic packaging industry. Through the integration of this advanced technology, the company has enhanced its production capabilities, improved efficiency, expanded its product offerings, and elevated the quality of its products. As they continue on their path of innovation and excellence, {} is well-positioned to shape the future of plastic manufacturing and deliver unparalleled value to its customers.

Discover the Benefits of Blow Molded Pots for Your Gardening Needs

[Headline]Blow Molded Pots: A Versatile and Sustainable Gardening Solution[Subheading]Introducing {} – A Leading Manufacturer of Blow Molded Pots[Date][City], [State] – [Month Day, Year][City], [State] – In a world where sustainability is paramount, gardening enthusiasts and professionals are constantly seeking eco-friendly and durable solutions for their plants. Blow molded pots have emerged as a game-changer in the horticulture industry, and {} has established itself as a prominent manufacturer in this space. Offering a wide range of blow molded pots, the company combines innovation and sustainability to cater to the growing demands of gardening enthusiasts worldwide.Blow molded pots have revolutionized the way plants are cultivated, offering a more sustainable alternative to traditional plastic pots. The process of blow molding involves melting plastic and blowing it into a mold, creating a durable and lightweight pot that is perfect for growing and nurturing plants. These pots are not only lightweight, making them easy to handle and transport, but also offer enhanced durability, preventing breakage and offering long-lasting performance.{} has emerged as a leading provider of blow molded pots, offering a diverse range of sizes, shapes, and colors to suit the diverse needs and preferences of gardeners. With a commitment to sustainability, {} uses only high-quality materials for their pots, ensuring that they are free from harmful chemicals and are recyclable.In an effort to contribute to a greener planet, {} implements various sustainable practices throughout the manufacturing process. The company uses energy-efficient equipment and techniques, reducing its carbon footprint significantly. Additionally, {} encourages its customers to recycle their blow molded pots once they are no longer in use, further promoting a circular economy.One of the key advantages of blow molded pots from {} is their versatility. These pots are suitable for both indoor and outdoor gardening, allowing plant enthusiasts to create beautiful displays in any environment. Whether it's a small herb garden indoors or a blooming array of flowers on a patio, {} offers pots that are designed to enhance the aesthetics of any space.Furthermore, the durability of blow molded pots allows gardeners to reuse them year after year, reducing the need for constant replacement and minimizing waste. This not only saves money in the long run but also helps in preserving the environment by minimizing plastic waste.With a commitment to customer satisfaction, {} offers exceptional customer service and support. Whether customers have queries regarding the selection of pots or need assistance with after-sales service, the dedicated team at {} is always ready to help.As gardening continues to gain popularity worldwide, the demand for sustainable and high-quality solutions such as blow molded pots is on the rise. {} recognizes this trend and strives to provide the best products to its customers. By combining innovation, durability, and sustainability, {} is revolutionizing the gardening industry one blow molded pot at a time.[Company Name] continues to expand its product range, regularly introducing new designs and sizes to cater to the ever-evolving needs of its customers. With a strong focus on sustainability and a commitment to customer satisfaction, {} is set to redefine the way gardening is pursued, while contributing to a greener and healthier planet.For more information about {} and its range of blow molded pots, please visit [website] or contact [phone number] or [email].###[Word Count: 600]

Blow Molding Techniques for Producing Pet Bottles

Blow Molding For Pet BottlesBlow molding is a manufacturing process used to create hollow plastic parts, including pet bottles. This process involves the use of a blow molding machine, which heats up plastic resin and then shapes it into a hollow form through the use of air pressure. Blow molding is a cost-effective and efficient way to produce large volumes of pet bottles for various industries, including the food and beverage, pharmaceutical, and personal care sectors.The company, {} is a leading manufacturer of blow molded pet bottles. With over 20 years of experience in the industry, they have established themselves as a trusted supplier of high-quality pet bottles for a wide range of applications. {} has a state-of-the-art manufacturing facility equipped with the latest blow molding machines, allowing them to produce pet bottles in different shapes, sizes, and colors to meet the specific needs of their customers.The company is committed to using the best materials and production techniques to ensure that their pet bottles are of the highest quality. They work closely with their clients to develop custom bottle designs and provide a range of services, including labeling and packaging, to meet their unique requirements. {} places a strong emphasis on sustainability and is continuously working to reduce their environmental impact by using eco-friendly materials and optimizing their manufacturing processes.In recent news, {} has announced the addition of new blow molding machines to their production line, enhancing their capacity to meet the growing demand for pet bottles. These new machines are equipped with advanced technology to improve efficiency and precision in the manufacturing process. This investment demonstrates {}'s commitment to staying at the forefront of the industry and providing their customers with the best possible products and services.The company's dedication to innovation and customer satisfaction has earned them a strong reputation in the market. Their pet bottles are known for their durability, clarity, and suitability for various packaging needs. {}'s extensive experience and expertise in blow molding enable them to offer competitive pricing and fast turnaround times, making them a preferred choice for businesses looking for reliable pet bottle suppliers.With a focus on quality, reliability, and sustainability, {} continues to be a key player in the blow molding industry. They are constantly exploring new opportunities to expand their product range and improve their manufacturing capabilities to better serve their customers. Their commitment to excellence and their strong track record make {} a trusted partner for businesses looking for top-notch pet bottles for their packaging needs.In conclusion, blow molding is an essential process for producing pet bottles, and {} is a leading manufacturer in this field. Their dedication to quality, innovation, and customer satisfaction sets them apart from their competitors and makes them a preferred choice for businesses in need of high-quality pet bottles. With a focus on sustainability and continuous improvement, {} is well-positioned to meet the evolving demands of the market and remain a key player in the blow molding industry.

Efficient Manual Molding Machine Revolutionizes Pet Plastic Gallon Production

[Company Introduction][Company Name] is a leading manufacturer and supplier of high-quality plastic molding machines in the industry. We have been innovating and providing reliable solutions to meet the growing demands of various sectors. Our commitment to quality and customer satisfaction has made us the preferred choice for businesses worldwide.Our state-of-the-art manufacturing facility boasts advanced technology and modern machinery, enabling us to produce top-notch machines that exceed industry standards. We have a team of experienced and skilled professionals who continuously strive to enhance our product range and deliver exceptional products that cater to the ever-evolving needs of our clients.With a strong focus on research and development, we consistently integrate cutting-edge technologies into our machines, ensuring optimal performance and reliability. Our dedication to innovation has helped us introduce the latest addition to our product line - the Pet Plastic Gallon Manual Molding Machine. This machine is a game-changer and offers numerous benefits to businesses in the plastic manufacturing industry.[News Content]Title: Introducing the Pet Plastic Gallon Manual Molding Machine - Revolutionizing the Plastic Manufacturing Industry[Location], [Date] - [Company Name], a market leader in plastic molding machines, is thrilled to announce the launch of its latest innovation - the Pet Plastic Gallon Manual Molding Machine. This breakthrough machine is set to revolutionize the plastic manufacturing industry by providing businesses with an efficient and cost-effective solution for producing high-quality plastic gallon containers.The Pet Plastic Gallon Manual Molding Machine is equipped with advanced features that contribute to its exceptional performance. Its user-friendly interface makes it easy for operators to set up molds and monitor the production process. The machine's flexibility allows it to handle different types of molds and produce a wide range of bottle sizes.One of the key advantages of this machine is its capability to produce gallon containers with PET (Polyethylene terephthalate) plastic material. PET is widely recognized for its durability, lightweight nature, and resistance to impact, making it an ideal choice for various applications such as packaging, beverages, and personal care products.Furthermore, the Pet Plastic Gallon Manual Molding Machine offers an eco-friendly solution to plastic manufacturing. The machine incorporates energy-saving features, optimized heating systems, and efficient cooling techniques, reducing both energy consumption and environmental impact. This aspect aligns with [Company Name]'s commitment to sustainability and creating a greener future."Introducing the Pet Plastic Gallon Manual Molding Machine showcases our dedication to meeting the evolving needs of our customers," said [Spokesperson]. "We are confident that this machine will enable businesses to streamline their production processes while ensuring the highest quality standards."In addition to its impressive features, the Pet Plastic Gallon Manual Molding Machine emphasizes safety and reliability. It includes safety mechanisms that prevent accidents and damage during operation. Regular maintenance and quality control checks guarantee its long lifespan, providing businesses with a sustainable and cost-effective solution.[Company Name] is recognized for its excellent after-sales service and technical support. Customers investing in the Pet Plastic Gallon Manual Molding Machine can expect comprehensive training for their operators, prompt assistance, and readily available spare parts to ensure uninterrupted production.As plastic gallon containers continue to gain popularity due to their convenience and versatility, businesses in the plastic manufacturing industry can rely on [Company Name]'s Pet Plastic Gallon Manual Molding Machine to meet the growing demands efficiently and profitably. This cutting-edge innovation reaffirms [Company Name]'s position as a leader in providing reliable and high-performance plastic molding machines.About [Company Name][Company Name] is a renowned manufacturer and supplier of plastic molding machines, catering to a wide range of industries. With a commitment to quality, innovation, and customer satisfaction, [Company Name] continues to set new standards in the plastic manufacturing industry. For more information, visit [Company Website].

Top 5 Blow Mold Halloween Decorations for Your Yard

Blow Mold Halloween Decoration - Adding a Spooky Touch to Your YardAs Halloween approaches, many people are getting ready to decorate their homes and yards with festive and spooky decorations. One popular option for outdoor Halloween decor is blow mold decorations. These vintage-style plastic decorations have been making a comeback in recent years, and are a great way to add a touch of nostalgia and whimsy to your Halloween display.() is a company that specializes in creating high-quality blow mold decorations for Halloween and other occasions. With a wide range of spooky designs, from pumpkins and witches to ghosts and skeletons, their products are perfect for adding a festive touch to your yard.Blow mold decorations have been a staple of Halloween decor for decades. Made of durable plastic, these decorations are designed to withstand the elements and can be used year after year. They come in a variety of shapes and sizes, making it easy to create a unique and eye-catching display in your yard.What sets ()'s blow mold decorations apart from others on the market is their attention to detail and commitment to quality. Each decoration is carefully crafted to ensure that it meets the company's high standards, resulting in products that are both durable and visually striking.In addition to their classic Halloween designs, () also offers a range of unique and eye-catching blow mold decorations for other holidays and occasions. From Christmas and Easter to birthdays and weddings, their products are perfect for adding a touch of festive flair to any celebration.For those looking to add a spooky touch to their Halloween decor this year, blow mold decorations are a great option. Whether used on their own or as part of a larger display, these vintage-style decorations are sure to make a statement in your yard. With their durability and timeless appeal, they are a great investment that can be enjoyed for many Halloweens to come.In addition to their blow mold decorations, () also offers a wide range of other Halloween decor products, including lights, inflatables, and indoor decorations. With their commitment to quality and customer satisfaction, they are a trusted source for all of your Halloween decorating needs.This year, why not add a touch of nostalgia and whimsy to your Halloween display with blow mold decorations from ()? With their durable construction, unique designs, and timeless appeal, these decorations are sure to become a beloved part of your Halloween traditions for years to come. Whether you're a long-time fan of blow mold decorations or new to the trend, ()'s products are a great choice for adding a spooky touch to your yard this Halloween.

Benefits of Magnesium Injection Molding for Automotive and Aerospace Industries

In the world of injection molding, a new process is making waves and revolutionizing the industry. Magnesium injection molding is providing manufacturers with a lightweight and durable alternative to traditional materials. This cutting-edge technology is the brainchild of {}, a leading company in the field of advanced manufacturing processes.{} has been a pioneer in the development of innovative manufacturing techniques for over 20 years. The company's commitment to research and development has led to the creation of numerous groundbreaking technologies that have reshaped the manufacturing landscape. Their latest innovation, magnesium injection molding, has the potential to transform industries ranging from automotive and aerospace to consumer electronics and medical devices.Magnesium injection molding offers several key advantages over traditional methods of production. First and foremost, magnesium is an incredibly lightweight material, making it ideal for applications where weight reduction is critical. Additionally, magnesium boasts an impressive strength-to-weight ratio, providing the durability and reliability necessary for high-performance applications. Furthermore, magnesium has excellent thermal conductivity, allowing for efficient heat dissipation in electronic devices and other heat-sensitive components.The process of magnesium injection molding involves melting the magnesium alloy and injecting it into a mold cavity under high pressure. This results in the creation of complex, high-precision parts with minimal material waste. Furthermore, the ability to produce thin-walled components with tight tolerances makes magnesium injection molding an attractive option for manufacturers seeking to optimize their production processes.One of the most significant benefits of magnesium injection molding is its environmental impact. Magnesium is a highly recyclable material, and the process of injection molding generates minimal waste. As companies around the world seek to reduce their carbon footprint and adopt more sustainable manufacturing practices, magnesium injection molding has emerged as a compelling solution.The potential applications of magnesium injection molding are vast and diverse. In the automotive industry, the use of magnesium components can lead to significant weight savings, improving fuel efficiency and reducing emissions. Similarly, in the aerospace sector, the lightweight and high-strength properties of magnesium make it an attractive material for aircraft and spacecraft components. Additionally, the consumer electronics industry can benefit from the thermal conductivity of magnesium, which can enhance the performance and longevity of electronic devices.{}'s expertise in magnesium injection molding has positioned the company as a leader in the field. Their state-of-the-art facilities and highly skilled workforce enable them to produce complex magnesium components with unparalleled precision and efficiency. Moreover, their commitment to quality and continuous improvement ensures that their products meet the exacting standards of their customers.The introduction of magnesium injection molding has the potential to disrupt traditional manufacturing processes and open up new opportunities for innovation across industries. As companies seek to stay ahead of the curve and embrace advanced materials and technologies, magnesium injection molding is poised to play a pivotal role in shaping the future of manufacturing.In conclusion, {}'s pioneering work in magnesium injection molding has set the stage for a new era of manufacturing excellence. The company's dedication to pushing the boundaries of what is possible in the field of advanced manufacturing processes has led to the development of a game-changing technology that is poised to make a profound impact on industries worldwide. As the demand for lightweight, durable, and sustainable materials continues to grow, the role of magnesium injection molding in shaping the future of manufacturing cannot be overstated. With {} at the forefront of this transformative technology, the possibilities are truly endless.

High-Quality 100ml Blow Molding Machine for Pet Bottles

The demand for plastic bottles and containers has been steadily increasing, especially with the rise of the packaging industry. In order to meet this demand, companies are constantly looking for advanced technologies and machinery to streamline their production process. One such company, [Company Name], has recently introduced a state-of-the-art 100ml Pet Blow Molding Machine, which is set to revolutionize the plastic packaging industry.The 100ml Pet Blow Molding Machine is designed to produce high-quality PET bottles and containers with a capacity of 100ml. This machine uses advanced blow molding technology to create a seamless and uniform finish on the bottles, ensuring top-notch quality and durability. With a production capacity of [XX] bottles per hour, this machine is capable of meeting the high production demands of the packaging industry.[Company Name] is a leading manufacturer and supplier of plastic processing machinery, with a strong focus on innovation and quality. With years of experience in the industry, the company has earned a reputation for delivering cutting-edge solutions that cater to the specific needs of their clients. The introduction of the 100ml Pet Blow Molding Machine is a testament to their commitment to providing advanced and efficient machinery for the packaging industry.The 100ml Pet Blow Molding Machine is equipped with advanced features that make it stand out from the competition. It incorporates a user-friendly interface and control system, which allows for easy operation and monitoring of the production process. Additionally, the machine is designed for low energy consumption and minimal maintenance, ensuring cost-effectiveness and reliability for the users.The machine is also equipped with a high-speed and precision mold clamping system, which ensures consistent and accurate production of PET bottles. This feature, combined with the machine's high-speed production capabilities, makes it an ideal choice for companies looking to optimize their production process and enhance their overall efficiency.In addition to its technological advancements, the 100ml Pet Blow Molding Machine is also designed with safety and environmental considerations in mind. It incorporates safety features such as emergency stop buttons and protective guarding to ensure a secure working environment for the operators. Furthermore, the machine is engineered to minimize waste and optimize the use of raw materials, making it a sustainable and eco-friendly option for the packaging industry.The introduction of the 100ml Pet Blow Molding Machine is expected to have a significant impact on the plastic packaging industry. With its advanced features, high production capacity, and commitment to sustainability, this machine is set to become a game-changer for companies looking to enhance their production capabilities and meet the growing demand for plastic bottles and containers.[Company Name] is proud to introduce the 100ml Pet Blow Molding Machine as part of their ongoing efforts to provide innovative and efficient solutions for the packaging industry. With their strong reputation for quality and reliability, the company is confident that this machine will set a new standard for PET bottle production and contribute to the overall growth and development of the industry.In conclusion, the introduction of the 100ml Pet Blow Molding Machine by [Company Name] represents a significant advancement in the plastic packaging industry. With its cutting-edge technology, high-speed production capabilities, and commitment to sustainability, this machine is poised to make a lasting impact on the industry and empower companies to enhance their production processes.

Silicone paw molds for small pets: A versatile addition to your crafting supplies

{company name}, a leading supplier of silicone molds and baking supplies, has recently launched a new product that is sure to excite pet owners and baking enthusiasts alike. The Small Pet Paw Silicone Molds are the latest addition to {company name}'s extensive range of high-quality molds, designed to add a touch of cuteness and creativity to homemade treats.These silicone molds are perfect for creating adorable paw-shaped goodies for small pets, such as dogs and cats. Whether it's for a special occasion, like a pet's birthday or adoption anniversary, or just to show some extra love and care, these molds make it easy to bake cute and tasty treats for beloved furry friends. The molds can be used to make a variety of treats, including biscuits, cookies, and even frozen treats for hot summer days.What sets these Small Pet Paw Silicone Molds apart is their durability and versatility. Made from food-grade silicone, they are flexible, non-stick, and easy to clean, making them ideal for both baking and freezing. The molds are also heat resistant and can withstand temperatures ranging from -40 to 230 degrees Celsius, making them safe for use in the oven, microwave, freezer, and dishwasher.In addition to being practical, these molds are also incredibly cute. The intricate paw design is sure to capture the hearts of pet owners, and the mini size of the paws makes them perfect for creating bite-sized treats for small pets. The molds come in a set of {number} and are available in a variety of colors, allowing users to mix and match to their heart's content.{company name} has always been committed to providing innovative and high-quality baking supplies, and the Small Pet Paw Silicone Molds are no exception. With their attention to detail and dedication to customer satisfaction, the company has quickly become a trusted and beloved brand among home bakers and pet owners."We are thrilled to introduce our Small Pet Paw Silicone Molds to the market," said {Name}, the founder of {company name}. "As pet lovers ourselves, we understand the joy of spoiling our furry friends with special treats. With these molds, we hope to empower pet owners to create homemade goodies that are not only delicious but also adorable."The launch of the Small Pet Paw Silicone Molds comes at a time when more and more people are turning to baking as a way to de-stress and express their creativity. With the rise of social media and the desire for personalized experiences, there is a growing demand for unique and visually appealing baking tools. {company name} recognizes this trend and is continuously working to develop new products that meet the needs of modern consumers.The response to the Small Pet Paw Silicone Molds has been overwhelmingly positive, with pet owners and baking enthusiasts alike expressing their excitement and satisfaction with the new product. Many have taken to social media to share their creations, showcasing the versatility and charm of the molds.In addition to the Small Pet Paw Silicone Molds, {company name} offers a wide range of silicone molds for various occasions and purposes, as well as other baking supplies such as decorating tools, baking mats, and cake molds. With a commitment to quality, creativity, and customer satisfaction, {company name} continues to be a go-to source for home bakers and pet owners alike.For those interested in getting their hands on the Small Pet Paw Silicone Molds or any other products from {company name}, they are available for purchase on the company's website and through select retailers. As the company looks towards the future, they are excited to continue bringing joy and innovation to the world of baking and pet care.

Common Blow Molding Machine Spare Parts Available in the Market

Title: Leading Blow Molding Machine Spare Parts Provider Announces New Innovations in the IndustryIntroduction:With an extensive history in the production of high-quality blow molding machine spare parts, [Company Name] is a renowned and globally recognized leader in the industry. Today, they have unveiled their latest advancements in blow molding technology, setting a new benchmark for efficiency, precision, and durability. By continuously pushing the boundaries of innovation, [Company Name] remains committed to meeting the evolving needs of their clients worldwide.Body:1. Company Background (100 words)Founded in [Year], [Company Name] has established itself as a trusted name in the blow molding industry. Their commitment to delivering exceptional quality, customer service, and cutting-edge solutions has earned them a strong reputation. Boasting a state-of-the-art manufacturing facility and a team of highly skilled professionals, the company has successfully catered to numerous clients spanning various industries globally.2. New Blow Molding Machine Spare Parts (200 words)In response to the growing demand for superior blow molding machine spare parts, [Company Name] has introduced a range of groundbreaking innovations. Their latest offerings harness advanced technologies to enhance efficiency, reliability, and productivity in blow molding processes.One notable addition is the precision-engineered molds designed to produce intricate shapes and sizes with unparalleled precision. These molds minimize material waste while ensuring optimal strength and uniformity in the final product. Furthermore, the improved cooling systems incorporated into the molds accelerate the production cycle, resulting in increased output and minimized downtime.Moreover, [Company Name] has developed state-of-the-art hydraulic systems that guarantee smooth and consistent equipment operation. These advanced systems optimize energy usage, reducing costs and environmental impact. Their innovative control panels offer user-friendly interfaces, allowing operators to monitor and adjust machine settings effortlessly.3. Commitment to Sustainability (150 words)Recognizing the global shift towards sustainable manufacturing, [Company Name] has steadfastly aligned its operations with eco-friendly practices. Their blow molding machine spare parts focus on reducing energy consumption, enhancing recyclability, and minimizing environmental footprint.By utilizing cutting-edge materials, [Company Name] has significantly lightened the weight of their spare parts while maintaining durability. This reduction in weight not only contributes to energy efficiency but also facilitates easier handling, installation, and maintenance.Another sustainable feature integrated into their spare parts is the incorporation of recyclable materials. This extends the lifecycle of the parts while reducing the industry's reliance on non-renewable resources.4. Global Outreach and Customer Support (150 words)[Company Name]'s commitment to excellence extends beyond the quality of their blow molding machine spare parts. They boast a global distribution network that ensures rapid delivery of spare parts to clients worldwide. This network is supported by a dedicated customer service team proficient in different languages, ensuring efficient communication and resolving customer queries promptly.To enhance customer experience, [Company Name] offers comprehensive after-sales support, including technical assistance, spare part consultation, and maintenance services. Their team of highly trained professionals is readily available to address any customer concerns, ensuring seamless operations throughout the product lifespan.Conclusion (100 words)[Company Name] continues to innovate and set new industry standards with their range of blow molding machine spare parts. Through their dedication to sustainability, advanced technology integration, and robust customer support, they have firmly established themselves as a trusted partner to clients worldwide. Their unwavering commitment to excellence reinforces their standing as an industry leader, poised to drive further advancements in the blow molding industry.

New Injection Blow Molding Machines Perfect for PMMA Production

Innovation and efficiency are the driving forces behind technological advancements in the manufacturing industry. This is especially true in the field of plastic molding, where precision and consistency are vital to producing quality products. This is why many companies invest in high-quality machines that speed up the manufacturing process without compromising product quality. One such investment is the Injection Blow Molding Machine for PMMA offered by a leading injection molding machine manufacturer.This machine is designed to provide maximum efficiency, consistency, and precision in the plastic molding process. PMMA, or polymethyl methacrylate, is a type of thermoplastic that is highly transparent and has excellent optical clarity. It's also resistant to environmental factors such as UV rays, making it a popular choice for various applications, including automotive parts, electronic housings, medical devices, and lighting components. Injection blow molding is a popular technique used to produce hollow objects such as bottles, jars, and containers.The Injection Blow Molding Machine for PMMA is a state-of-the-art machine designed specifically for this molding technique. It has a clamping force of 70 tons and can produce containers with a volume of 10ml to 500ml. The machine has a high-speed injection system that ensures fast, efficient, and precise filling of the mold cavity. It also has a blow molding system that delivers consistent and high-quality blow-molded products.Moreover, the machine's human-machine interface (HMI) is user-friendly and easy to operate. This ensures a smooth and hassle-free plastic molding process, even for operators with minimal experience. The HMI features a touch screen that allows the operator to easily control and adjust various process parameters, such as injection pressure, blowing pressure, and mold opening and closing speeds.The Injection Blow Molding Machine for PMMA is also designed to be energy-efficient. It has a low power consumption, reducing the cost of operation and increasing the machine's lifespan. It's also fitted with a servo motor that enables precise control of the injection and blowing processes, reducing waste and improving the overall product quality.As a leading manufacturer of injection molding machines, the company is committed to providing high-quality solutions to its customers. They offer a wide range of machines that cater to different molding techniques and production volumes. They also ensure that their machines are reliable, efficient, and durable, ensuring that their customers get the best value for their investment.The company also provides after-sales support to its customers, ensuring that their machines are well-maintained and in good condition. They offer training and technical support to their clients, enabling them to operate the machines efficiently and troubleshoot any issues that may arise.The Injection Blow Molding Machine for PMMA is just one of the many high-quality machines offered by this leading injection molding machine manufacturer. Their commitment to innovation, efficiency, and customer satisfaction has made them a trusted partner for many businesses across different industries.In conclusion, the Injection Blow Molding Machine for PMMA is an excellent investment for businesses looking to improve their plastic molding process's speed, efficiency, and quality. It's designed with state-of-the-art technology, user-friendly interfaces, and energy-efficient components that enable businesses to achieve high-quality production at a lower cost. With its range of features and benefits, this machine is a valuable addition to any plastic molding operation.