Blow Molding Techniques for Producing Pet Bottles

By:Admin

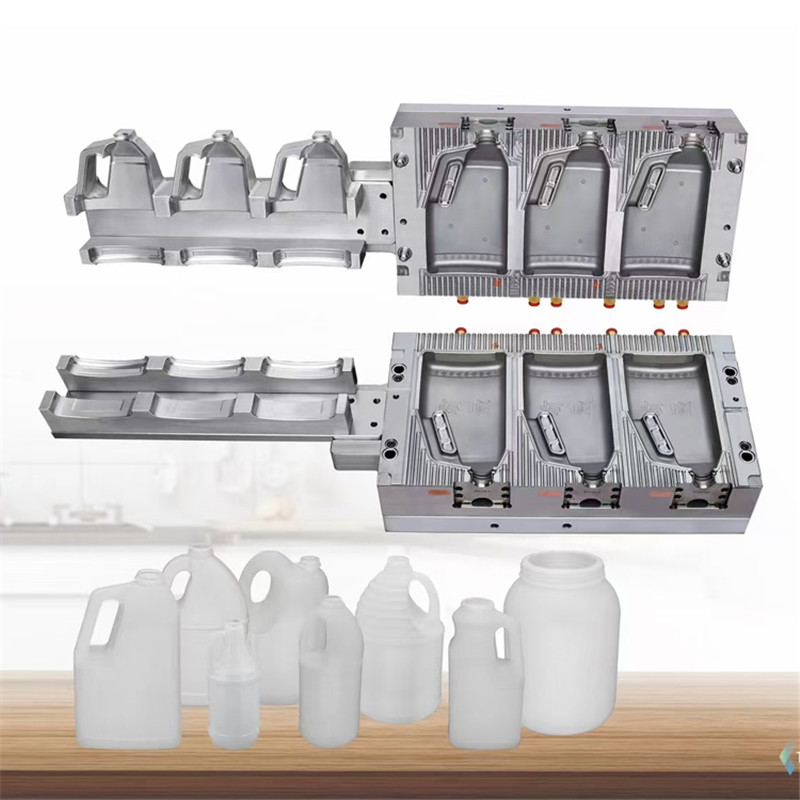

Blow molding is a manufacturing process used to create hollow plastic parts, including pet bottles. This process involves the use of a blow molding machine, which heats up plastic resin and then shapes it into a hollow form through the use of air pressure. Blow molding is a cost-effective and efficient way to produce large volumes of pet bottles for various industries, including the food and beverage, pharmaceutical, and personal care sectors.

The company, {} is a leading manufacturer of blow molded pet bottles. With over 20 years of experience in the industry, they have established themselves as a trusted supplier of high-quality pet bottles for a wide range of applications. {} has a state-of-the-art manufacturing facility equipped with the latest blow molding machines, allowing them to produce pet bottles in different shapes, sizes, and colors to meet the specific needs of their customers.

The company is committed to using the best materials and production techniques to ensure that their pet bottles are of the highest quality. They work closely with their clients to develop custom bottle designs and provide a range of services, including labeling and packaging, to meet their unique requirements. {} places a strong emphasis on sustainability and is continuously working to reduce their environmental impact by using eco-friendly materials and optimizing their manufacturing processes.

In recent news, {} has announced the addition of new blow molding machines to their production line, enhancing their capacity to meet the growing demand for pet bottles. These new machines are equipped with advanced technology to improve efficiency and precision in the manufacturing process. This investment demonstrates {}'s commitment to staying at the forefront of the industry and providing their customers with the best possible products and services.

The company's dedication to innovation and customer satisfaction has earned them a strong reputation in the market. Their pet bottles are known for their durability, clarity, and suitability for various packaging needs. {}'s extensive experience and expertise in blow molding enable them to offer competitive pricing and fast turnaround times, making them a preferred choice for businesses looking for reliable pet bottle suppliers.

With a focus on quality, reliability, and sustainability, {} continues to be a key player in the blow molding industry. They are constantly exploring new opportunities to expand their product range and improve their manufacturing capabilities to better serve their customers. Their commitment to excellence and their strong track record make {} a trusted partner for businesses looking for top-notch pet bottles for their packaging needs.

In conclusion, blow molding is an essential process for producing pet bottles, and {} is a leading manufacturer in this field. Their dedication to quality, innovation, and customer satisfaction sets them apart from their competitors and makes them a preferred choice for businesses in need of high-quality pet bottles. With a focus on sustainability and continuous improvement, {} is well-positioned to meet the evolving demands of the market and remain a key player in the blow molding industry.

Company News & Blog

Innovative Blow Molded Sand-Filled Kettlebell: A Functional Fitness Essential

Blow Molded Sand-Filled Kettlebell (need remove brand name)Kettlebells have become a popular fitness tool due to their ability to provide a full-body workout and improve strength, stability, and endurance. With the increasing demand for home fitness equipment, a leading company in the fitness industry has introduced a new blow molded sand-filled kettlebell that is set to revolutionize the way people workout at home.The company, based in (location), is known for its high-quality fitness products that are designed to meet the needs of both fitness enthusiasts and professional athletes. With a strong commitment to innovation and excellence, the company has been at the forefront of developing cutting-edge fitness equipment that delivers outstanding results.The new blow molded sand-filled kettlebell is the latest addition to the company's extensive range of fitness products. Designed to provide a challenging and effective workout, this kettlebell is filled with sand using a blow molding process. This innovative technique ensures that the kettlebell has a durable and long-lasting construction, making it ideal for intense workout sessions.One of the key features of this kettlebell is its ergonomic handle, which is designed to provide a comfortable and secure grip during workouts. This allows users to perform a wide range of exercises with confidence, knowing that the kettlebell will not slip or cause any discomfort. Additionally, the kettlebell is available in a range of weights, making it suitable for beginners and experienced fitness enthusiasts alike.The company's commitment to quality is reflected in the design and construction of the blow molded sand-filled kettlebell. Made from high-quality materials, this kettlebell is built to withstand the demands of regular use, ensuring that it remains a reliable fitness tool for years to come. Furthermore, the sand filling provides a balanced weight distribution, allowing for smooth and controlled movements during workouts.In addition to its outstanding performance, the blow molded sand-filled kettlebell is also designed with convenience in mind. Its compact size and versatile nature make it easy to store and use in a variety of spaces, whether at home or in a commercial fitness facility. This means that users can enjoy a challenging workout without the need for bulky or expensive equipment.As the demand for home fitness equipment continues to grow, the introduction of the new blow molded sand-filled kettlebell comes at a perfect time. With its combination of durability, functionality, and convenience, this kettlebell is set to become a popular choice for individuals looking to enhance their fitness routine from the comfort of their own home.The company's dedication to providing innovative fitness solutions is evident in the development of this kettlebell, and they are proud to offer a product that meets the needs of their customers. With a focus on quality and performance, they are committed to supporting individuals in achieving their fitness goals and leading a healthy lifestyle.In conclusion, the introduction of the blow molded sand-filled kettlebell represents a significant milestone for the company, highlighting their ongoing commitment to delivering exceptional fitness products. As the demand for home fitness solutions continues to rise, this innovative kettlebell is well-positioned to meet the needs of users seeking a versatile, durable, and effective workout tool. With its ergonomic design, durable construction, and convenient size, the blow molded sand-filled kettlebell is set to make a positive impact on the fitness industry, providing individuals with the means to achieve their fitness goals on their own terms.

Complete Guide to Setting Up a Blow Molding Machine

In today's fast-paced manufacturing industry, efficiency and precision are essential for a company's success. One company that has been a pioneer in the field of blow molding machines is {}. With their state-of-the-art technology and commitment to innovation, they have revolutionized the way plastic products are manufactured.Recently, {} has announced the setup of their latest blow molding machine, a new addition to their already impressive lineup of equipment. This new machine is set to further enhance the company's production capabilities and solidify their position as a leading provider of blow molding solutions.The setup of this new blow molding machine represents a significant milestone for {}. It showcases the company's dedication to staying at the forefront of technological advancements in the industry and their ongoing commitment to providing their customers with the best possible products and services. The machine is equipped with the latest features and enhancements that will allow {} to meet the growing demand for high-quality plastic products in the market.With this new setup, {} is poised to significantly increase their production capacity, allowing them to take on larger orders and meet tighter deadlines. This will enable the company to better serve their customers and meet the ever-evolving needs of the market.In addition to enhancing production capabilities, the new blow molding machine setup will also bring about improvements in efficiency and cost-effectiveness for {}. The advanced technology incorporated into the machine will streamline the manufacturing process, reducing production times and minimizing wastage. This will ultimately translate to cost savings for the company, which they can pass on to their customers.Furthermore, the setup of this new machine exemplifies {}'s commitment to sustainability and environmental responsibility. The machine is designed to minimize energy consumption and reduce the overall carbon footprint of the manufacturing process. By investing in eco-friendly technology, {} is playing a crucial role in contributing to a more sustainable and environmentally conscious manufacturing industry.The setup of the new blow molding machine is a testament to the relentless pursuit of excellence that {} embodies. The company has consistently demonstrated their ability to adapt to the changing needs of the market and invest in the latest technology to stay ahead of the competition. By continuously innovating and improving their capabilities, {} has established themselves as a trusted and dependable partner for businesses seeking high-quality blow molding solutions.In conclusion, the setup of the new blow molding machine marks a significant achievement for {}. It showcases the company's unwavering commitment to excellence, innovation, and sustainability. With this new addition to their lineup of equipment, {} is poised to further solidify their position as a leader in the blow molding industry and continue providing their customers with exceptional products and services.

Discover the Latest Innovations in Pet Blow Machine Technology

PET Blow Machine enhances efficiency and quality in the production process.In the competitive world of manufacturing, efficiency and quality are paramount. This is where the PET Blow Machine comes into play, revolutionizing the production process for companies in various industries.The PET Blow Machine, developed and produced by a leading manufacturing company, is a state-of-the-art piece of equipment designed to streamline the process of creating PET bottles and containers. With its innovative technology and advanced features, this machine is capable of producing high-quality products at a faster rate, ultimately improving the overall efficiency of the production process.The company behind the PET Blow Machine is a global leader in manufacturing equipment for the packaging industry. With a strong focus on innovation and customer satisfaction, the company has gained a reputation for delivering cutting-edge solutions that meet the evolving needs of its clients.Founded over three decades ago, the company has continuously strived for excellence in its field. With a team of experienced engineers and designers, the company has been able to develop a wide range of products that cater to the diverse needs of its clients. From blow molding machines to preform making machines, the company's product portfolio is extensive and continues to grow as new technologies emerge.The PET Blow Machine is one of the company's flagship products, and it has been well-received by clients around the world. Its ability to produce high-quality PET bottles and containers with precision and efficiency has made it a go-to solution for many manufacturing companies across different industries. With a focus on user-friendly design and advanced automation features, the machine has been lauded for its ease of use and reliability.One of the key features of the PET Blow Machine is its energy-efficient design. By optimizing the use of resources and reducing waste, the machine helps companies minimize their environmental impact while also cutting down on operational costs. This aligns with the company's commitment to sustainability and corporate responsibility, as it continues to develop products that contribute to a greener and more sustainable future.In addition to its efficiency and sustainability benefits, the PET Blow Machine also offers a high level of customization. Clients can choose from a range of options to tailor the machine to their specific production needs, ensuring that they can achieve the results they desire without compromise. This flexibility has been a major selling point for the machine, as it allows companies to adapt to changing market demands and stay ahead of the competition.As demand for PET bottles and containers continues to grow, the PET Blow Machine has become an indispensable tool for many manufacturing companies. Its ability to deliver consistent, high-quality results at a rapid pace has set a new standard for production efficiency in the industry. With the support of the company behind it, the machine is poised to continue making waves in the global manufacturing landscape.Looking to the future, the company remains committed to pushing the boundaries of innovation and delivering solutions that exceed the expectations of its clients. With an eye on emerging technologies and market trends, the company is well-positioned to continue driving positive change in the industry. As a trusted partner for manufacturing companies around the world, the company will undoubtedly remain at the forefront of the industry for years to come.In conclusion, the PET Blow Machine has proven to be a game-changer for manufacturing companies seeking to enhance their production processes. With its focus on efficiency, quality, and sustainability, this state-of-the-art machine is a testament to the company's dedication to innovation and customer satisfaction. As it continues to gain recognition in the global market, the PET Blow Machine is shaping the future of manufacturing and paving the way for a more efficient and sustainable industry.

Unlocking the Secrets to Superior Blow Moulding Techniques

Blow Moulding Super – Leading the Way in Sustainable Packaging SolutionsBlow Moulding Super (BMS), a leading provider of blow moulding solutions, has been pioneering sustainable packaging solutions since its inception. With a focus on innovation and continuous improvement, the company is committed to reducing its environmental footprint while offering cost-effective and high-quality packaging solutions to its customers.Founded in 1997, BMS has grown from a small regional provider to a worldwide network of companies with a presence in over 30 countries. The company’s success is built on its robust engineering expertise, coupled with its unwavering commitment to customer satisfaction. With state-of-the-art manufacturing facilities and a team of highly skilled professionals, BMS is capable of producing customised packaging solutions that meet the unique needs of its clients.BMS’s sustainable approach to packaging is based on three key pillars: reducing material use, maximising reusability, and optimising recyclability. By using less material in its manufacturing process, the company reduces its energy consumption and carbon footprint. BMS also prioritises reusability and recycling, ensuring that its products are designed with a circular economy in mind. These principles have allowed BMS to develop a range of sustainable packaging solutions that meet the highest environmental standards.One of BMS’s flagship products is its line of mono-material packaging solutions. These packages are used in a wide range of industries, from food and beverage to cosmetics and personal care. Mono-material packaging is made from a single material, which simplifies the recycling process and reduces waste. BMS’s mono-material packaging solutions are available in a variety of shapes and sizes, and can be customised to meet the specific needs of each client.BMS also offers a range of other sustainable packaging solutions, including lightweight bottles and containers made from recycled materials. These products are designed to reduce the amount of material used while maintaining the necessary levels of protection and durability. BMS’s lightweight bottles and containers are suitable for a range of applications, including beverage, household and personal care products.In addition to its focus on sustainability, BMS is also committed to delivering exceptional customer service. The company’s sales and customer service teams work closely with clients to understand their unique needs and develop customised packaging solutions that meet those needs. BMS’s engineering team is also available to provide technical support and product development services, ensuring that its clients receive the highest quality products and services.BMS’s commitment to sustainability has been recognised by a number of industry groups and organisations. In 2019, the company was awarded the prestigious Greener Package Award for its sustainable packaging solutions. This award recognises companies that demonstrate a commitment to sustainable packaging and have made significant contributions to reducing their environmental impact.The future of packaging is in sustainability, and BMS is at the forefront of this market trend. With its focus on innovation, high-quality products, and exceptional customer service, the company is well-positioned to continue leading the way in sustainable packaging solutions for years to come.

New Mould Designs for Bubble Caps

Bubble Cap Mould: An Essential Tool for the Chemical IndustryBubble cap moulds are essential for the chemical industry. They are used to manufacture a wide range of products that are ubiquitous in our daily lives. From household cleaners to plastics, bubble cap moulds are used to make the caps that seal these products.Bubble cap moulds are the cornerstone of many industries and are manufactured by only a few companies worldwide. One such company that produces bubble cap moulds is headquartered in China. This company specializes in the design and manufacture of various types of moulds and has been in the industry for over 20 years.Bubble cap moulds are typically made of high-quality stainless steel. The process begins by designing the mould, which takes into account factors such as the dimensions and shape of the cap, as well as other specifications such as the material of the cap and the temperature and pressure conditions under which it will be produced.The design is then manufactured using CNC machines with high precision to ensure that the mould conforms to the exact specifications. Once the mould is completed, it is subjected to rigorous testing to ensure that it is of the highest quality standard.The chemical industry relies heavily on bubble cap moulds to produce a variety of products. Chemical companies use bubble caps to produce a variety of products, including various chemicals, household cleaners, and plastics, among others. Bubble caps are also used in the production of medical equipment, ensuring that the products are sterile and free from contamination.Bubble cap moulds are highly versatile and can be customized to fit the specific needs of each industry. They can be designed to work under varying pressure and temperature conditions and can be adapted to produce different types of caps, including twist-off and snap-on caps.One of the biggest advantages of using bubble cap moulds is their high precision. Bubble cap moulds are designed to produce caps at a high precision level, ensuring that the caps meet strict quality control standards. This level of precision also ensures that the caps are consistent in size, shape, and quality, which is important in maintaining product integrity.Moreover, bubble cap moulds are highly efficient. The moulds are designed to produce multiple caps at once, which saves a significant amount of time. This efficiency is particularly important in the chemical industry, where large volumes of products need to be produced quickly and efficiently.The Chinese company offers a wide range of bubble cap moulds to meet the needs of various industries. They specialize in producing high-quality bubble cap moulds that meet the strictest quality standards. The company has a team of highly skilled engineers and technicians who are equipped with state-of-the-art equipment to ensure the best quality products.In addition to the production of bubble cap moulds, the company offers a comprehensive range of services, including design and development, customization, repair, and maintenance. The team is available to provide technical support and advice to clients, ensuring that they get the best products and services.In conclusion, bubble cap moulds are an essential tool in the chemical industry. They are used to manufacture a wide range of products, including various chemicals, household cleaners, and plastics, among others. The Chinese company specializes in the production of high-quality bubble cap moulds that are designed to meet the strictest quality standards. With over 20 years of experience in the industry, the company offers a wide range of services, including design and development, customization, repair, and maintenance. Their team of highly skilled engineers and technicians ensures the best quality products and services, making them a valuable resource for clients in the chemical industry.

12 Inch Plastic Blow Molded Wheel: A Durable and Versatile Solution for Various Applications.

Top Plastic Injection Molding Services for Your Business Needs

[Precision Plastic Injection Molding Company] is a leading provider of plastic injection molding services, with a focus on delivering high-quality, custom plastic parts to a wide range of industries. With over 20 years of experience in the industry, [Precision Plastic Injection Molding Company] has earned a reputation for excellence and innovation, and is committed to meeting the unique needs of each and every customer.As a full-service plastic injection molding company, [Precision Plastic Injection Molding Company] offers a comprehensive range of services, including product design and development, mold design and construction, and precision molding and assembly. The company's state-of-the-art facility is equipped with the latest in injection molding technology, allowing for the production of complex, high-precision parts with tight tolerances.One of the key differentiators of [Precision Plastic Injection Molding Company] is its dedication to quality and customer satisfaction. The company employs a rigorous quality control process to ensure that every part that leaves its facility meets the highest standards of excellence. This commitment to quality has earned [Precision Plastic Injection Molding Company] numerous certifications and awards, and has established the company as a trusted partner for businesses across a wide range of industries.In addition to its focus on quality, [Precision Plastic Injection Molding Company] is also dedicated to sustainability and environmental responsibility. The company has implemented a number of initiatives to reduce its environmental impact, including the use of recycled materials and energy-efficient manufacturing processes. By prioritizing sustainability, [Precision Plastic Injection Molding Company] is able to help its customers meet their own sustainability goals while also minimizing its own carbon footprint.Recently, [Precision Plastic Injection Molding Company] announced a new partnership with a leading technology company to further enhance its capabilities and expand its offerings. This partnership will enable [Precision Plastic Injection Molding Company] to leverage the latest advancements in injection molding technology, and will allow the company to offer even more innovative solutions to its customers."We are thrilled to announce this new partnership, which will allow us to continue pushing the boundaries of what is possible in plastic injection molding," said [CEO of Precision Plastic Injection Molding Company]. "By combining our expertise with the cutting-edge technology of our partner, we will be able to offer our customers even more advanced and efficient solutions for their plastic part needs."The partnership comes at an exciting time for [Precision Plastic Injection Molding Company], as the company continues to experience rapid growth and expansion. In addition to its new partnership, [Precision Plastic Injection Molding Company] has also recently completed a significant expansion of its facility, adding new injection molding machines and increasing its production capacity to meet the growing demand from its customers."We are incredibly proud of the growth that we have experienced in recent years, and we are excited to continue expanding our capabilities and offerings to better serve our customers," said [CEO of Precision Plastic Injection Molding Company]. "With our new partnership and expanded facility, we are well-positioned to continue providing the high-quality, custom solutions that our customers have come to expect from us."Looking ahead, [Precision Plastic Injection Molding Company] is focused on continuing to innovate and grow, while maintaining its commitment to quality, sustainability, and customer satisfaction. With its new partnership and expanded capabilities, the company is well-positioned to remain a leader in the plastic injection molding industry for years to come.

Small Manufacturing Machines in China: A Closer Look at the Industry

China Small Manufacturing Machines, a leading company in the small manufacturing industry, has been making waves with its innovative and efficient machines. The company, which was founded in 2005, has quickly become a key player in the field, offering a wide range of machines that cater to the needs of small businesses and manufacturing enterprises.With a strong focus on research and development, China Small Manufacturing Machines has been able to stay ahead of the competition by consistently delivering cutting-edge technology and top-quality products. The company's commitment to innovation has earned it a stellar reputation in the industry, and it is now considered a go-to source for small manufacturing machines.One of the key factors that sets China Small Manufacturing Machines apart from its competitors is its dedication to providing cost-effective solutions without compromising on quality. The company's machines are designed to be highly efficient, helping businesses increase their productivity while keeping costs down. This has made China Small Manufacturing Machines a preferred choice for small businesses looking to improve their manufacturing capabilities without breaking the bank.In addition to its focus on affordability, China Small Manufacturing Machines also takes great pride in offering personalized service to its clients. The company understands that every business has its own unique needs and challenges, and it works closely with each client to provide tailored solutions that meet their specific requirements. This level of personalized attention has helped China Small Manufacturing Machines build strong, long-lasting relationships with its customers.One of the key highlights of China Small Manufacturing Machines' product line is its range of CNC machines. These state-of-the-art machines utilize computer numerical control to perform a wide range of manufacturing tasks with unparalleled precision and efficiency. The company's CNC machines have been a game-changer for many businesses, enabling them to take their production processes to the next level.Another standout product from China Small Manufacturing Machines is its line of 3D printing machines. These cutting-edge devices have revolutionized the manufacturing industry by allowing businesses to create complex, custom-designed components with ease. The company's 3D printing machines are known for their reliability and high-quality output, making them a popular choice for businesses looking to incorporate additive manufacturing into their operations.In recent years, China Small Manufacturing Machines has also ventured into the world of automation, offering a range of robotic solutions for small businesses. These innovative machines have helped businesses streamline their production processes, reduce labor costs, and improve overall efficiency. As the demand for automation continues to rise, China Small Manufacturing Machines is well-positioned to meet the needs of businesses looking to embrace this technology.Looking ahead, China Small Manufacturing Machines remains committed to pushing the boundaries of innovation and delivering unparalleled value to its customers. The company continues to invest heavily in research and development, with the aim of introducing even more advanced and cost-effective solutions to the market.With a strong track record of success, a commitment to quality, and a customer-centric approach, China Small Manufacturing Machines is poised to remain a leader in the small manufacturing industry for many years to come. Businesses in need of high-quality, affordable manufacturing machines can confidently turn to China Small Manufacturing Machines for all their needs.

Top Injection Mold Parts You Need for Your Project

Injection Mold Parts List (need remove brand name), combined with the company introduction {}[Company Name], a leading manufacturer of injection mold parts, has announced the release of a comprehensive list of injection mold parts for various industries. The company has established a strong reputation for producing high-quality injection mold parts, and the new list promises to further solidify its position as a go-to source for top-notch components.The injection mold parts list includes a wide range of products, from standard components to highly specialized parts. Some of the key items featured in the list include injection mold bases, ejector pins, ejector sleeves, core pins, and mold inserts. In addition, the list also includes a variety of accessories such as mold cooling components, mold cleaning supplies, and mold maintenance tools.With a focus on precision and durability, each injection mold part is manufactured to exact specifications using advanced technology and high-quality materials. The company takes pride in its ability to meet the diverse needs of its customers, offering customization options to ensure that the parts align with specific project requirements.In addition to the wide array of standard components, the company also specializes in producing custom injection mold parts. This service allows customers to work closely with the company's experienced engineers to design and create unique parts tailored to their exact needs. This comprehensive approach to injection mold part production sets the company apart from its competitors and has earned it a loyal customer base across various industries.In line with its commitment to quality and innovation, the company continuously invests in research and development to enhance its product offerings. This dedication to improvement ensures that the company remains at the forefront of the injection molding industry, constantly evolving to meet the evolving demands of its customers.The release of the injection mold parts list is an exciting development for the company, as it represents a culmination of its efforts to provide a one-stop solution for injection mold part needs. By consolidating its product offerings into a comprehensive list, the company aims to simplify the process for its customers, making it easier for them to find the parts they require for their projects.As a company spokesperson noted, "We are thrilled to unveil our new injection mold parts list, which showcases our extensive range of high-quality components. Whether our customers are looking for standard parts or custom solutions, they can rely on us to deliver products that meet their exact specifications. Our goal is to be a trusted partner for our customers, providing them with the parts they need to bring their projects to life."The injection mold parts list is now available for viewing on the company's website, where customers can browse the full range of products and learn more about the customization options available. With its unwavering commitment to excellence, [Company Name] is poised to continue setting the standard for injection mold part manufacturing, catering to the diverse needs of its customers with precision and expertise.In conclusion, the release of the injection mold parts list by [Company Name] signifies a significant milestone for the company, reflecting its dedication to providing top-quality components for the injection molding industry. With its extensive product range and customized solutions, the company is well-positioned to serve as a reliable partner for customers seeking high-quality injection mold parts. As the company continues to innovate and expand its offerings, it remains a leading force in the injection mold part manufacturing sector, delivering excellence and reliability to its valued customers.

Expert Insights into the World of Plastic Mould Maker and Injection Mold Production

Plastic Mould Maker Injection Mold, a renowned manufacturer of high-quality and cost-effective injection molds, is revolutionizing the plastic molding industry with its innovative designs and efficient manufacturing process.Founded in 2005, the company has been a leading player in the global injection molding industry, providing customized solutions to its clients worldwide. With a team of highly skilled engineers and technicians, the company has been catering to diverse industries such as automotive, medical, household appliances, and electronics.The team at Plastic Mould Maker Injection Mold is committed to delivering exceptional quality products to its clients while adhering to strict deadlines. The company's state-of-the-art manufacturing facility is equipped with advanced equipment and tools, allowing them to produce molds of various sizes, shapes, and complexities.The company's injection molds boast of superior quality, dimensional accuracy, and durability. The molds are designed using advanced software programs, ensuring precision in every stage of the manufacturing process. Besides, the company also follows strict quality control measures to ensure that each mold produced is consistent with the client's requirements.Plastic Mould Maker Injection Mold's success can be attributed to its experienced team of engineers and technicians who possess extensive knowledge and experience in the injection molding industry. The company provides its staff with regular training and updates on the latest technologies and advancements in the industry. This ensures that the team is well equipped to handle any challenging project, resulting in high-quality products.The company's focus on innovation and research has led to the development of numerous innovative molds that have been well received by clients worldwide. Besides, Plastic Mould Maker Injection Mold places utmost importance on sustainability, and all its molds are produced using environmentally friendly materials.The company's client base comprises of an array of businesses globally, including small and medium-sized enterprises to large multinational corporations. The company's ability to cater to a wide range of clients is due to its exceptional customer service. The company's team works closely with clients throughout the project, providing regular updates and ensuring that the final product meets their expectations.The injection molding industry is highly competitive, and Plastic Mould Maker Injection Mold has managed to maintain its edge by providing high-quality molds at a cost-effective price. The company works with clients to develop molds that not only meet their needs but also help them save production costs in the long run.In conclusion, Plastic Mould Maker Injection Mold is a leader in the injection molding industry, dedicated to providing exceptional quality molds that meet the needs of clients worldwide. The company's innovative designs, efficient manufacturing process, and commitment to sustainability set it apart from competitors in the industry. With a focus on client satisfaction and exceptional customer service, the company is set to continue its growth trajectory, serving diverse clients from different industries with its exceptional products and services.