Discover the benefits of blow molding for PET bottles

[Company Name] is currently revolutionizing the packaging industry with its innovative blow molding technology for manufacturing PET bottles. The company, [Company Name], has been at the forefront of this technology, setting new standards for quality and sustainability in the production of PET bottles.Blow molding is a manufacturing process used to create hollow plastic parts, such as bottles and containers. The process begins with melting down plastic and forming it into a parison, or a tube-like piece of plastic. The parison is then placed into a mold, where it is inflated using compressed air, taking on the shape of the mold cavity. Finally, the newly formed plastic bottle is ejected from the mold and trimmed to its final shape.[Company Name] has perfected this blow molding technology to produce high-quality PET bottles that meet the highest standards of durability, clarity, and sustainability. Their PET bottles are widely used in the packaging of beverages, personal care products, and household cleaning products.The company has invested heavily in state-of-the-art blow molding equipment, ensuring that their PET bottles are produced with precision and consistency. This dedication to quality has earned [Company Name] a reputation as a trusted supplier of PET bottles to leading brands in various industries.In addition to quality, [Company Name] is committed to sustainability in their manufacturing processes. The company utilizes advanced recycling and reprocessing technologies to minimize waste and reduce their environmental impact. By incorporating recycled materials into their production processes, [Company Name] is contributing to the circular economy and promoting a more sustainable approach to packaging.One of the key advantages of blow molding technology is its ability to produce lightweight yet strong bottles, reducing the amount of raw material required and the overall carbon footprint of the packaging. [Company Name] has embraced this advantage and is continuously innovating to further improve the sustainability of their PET bottles.Furthermore, [Company Name] is dedicated to meeting the specific needs of their customers. They offer a wide range of bottle sizes, shapes, and neck finishes, as well as custom design and branding options. This versatility allows [Company Name] to provide tailored packaging solutions to their clients, helping them to enhance their brand image and customer experience.With their cutting-edge blow molding technology, commitment to sustainability, and customer-focused approach, [Company Name] has positioned itself as a leader in the PET bottle manufacturing industry. As the demand for eco-friendly packaging continues to grow, [Company Name] is well-positioned to meet this demand and drive the industry forward.[Company Name] is also dedicated to ongoing research and development efforts to further improve their blow molding technology and expand their product offerings. By staying ahead of the curve, [Company Name] aims to continue setting new standards for excellence and innovation in the packaging industry.In conclusion, [Company Name] is a pioneering force in the field of blow molding technology for PET bottles. Their unwavering commitment to quality, sustainability, and customer satisfaction has earned them a prominent position in the market. With their advanced manufacturing capabilities and dedication to innovation, [Company Name] is well-equipped to meet the evolving needs of the packaging industry and continue leading the way in the production of PET bottles.

Read More

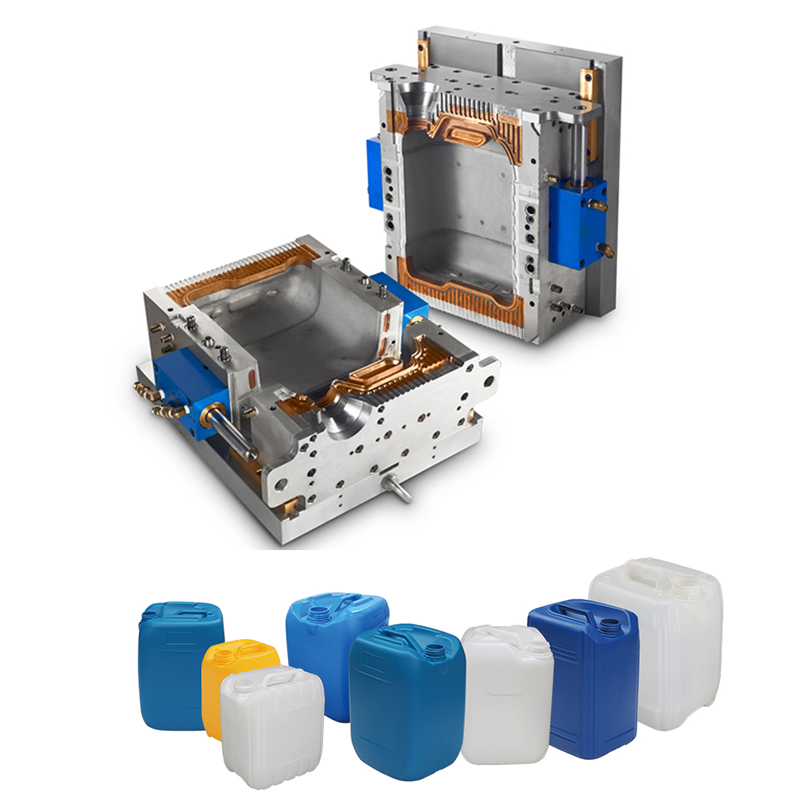

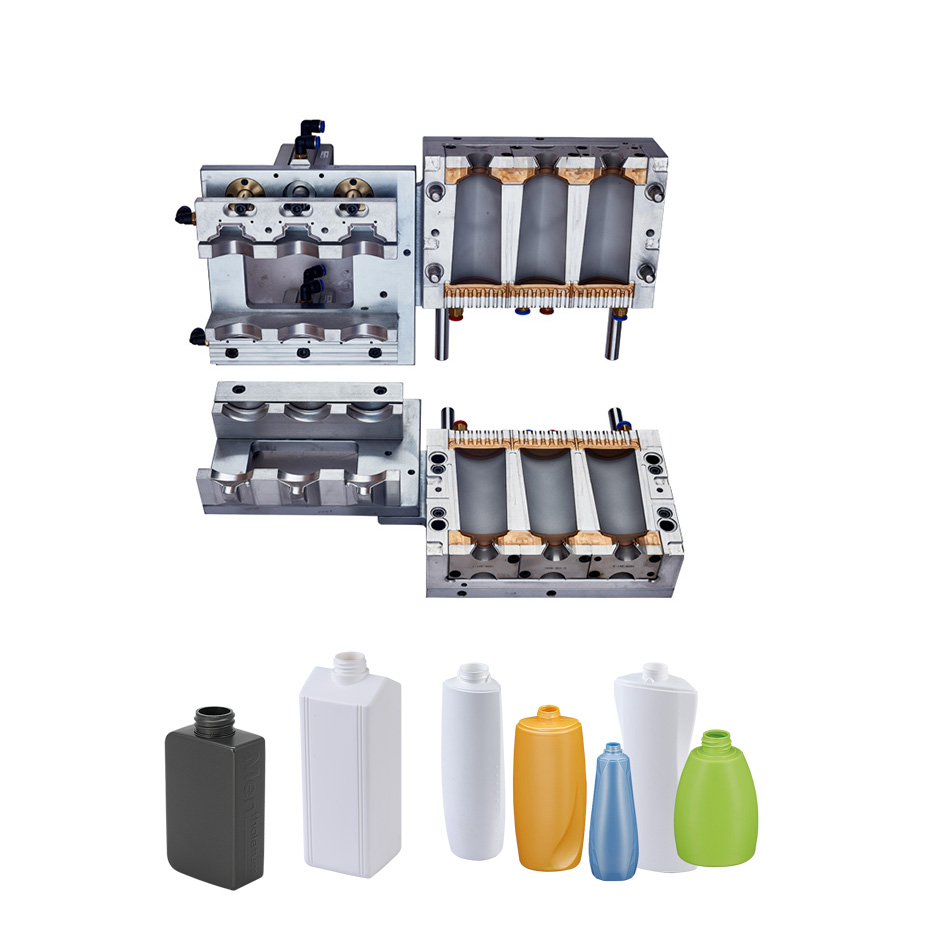

Incredible Advancements in Injection Molding Technology

Plastic Mould Injection Molding: The Ultimate Solution for High-Quality Parts ProductionWhen it comes to manufacturing high-quality plastic parts, choosing the right injection mold manufacturer is paramount. That's where Plastic Mould Injection Molding comes in. With years of experience in injection molding, the company has become a leader in the field, delivering exceptional products to clients across the globe.What Is Plastic Mould Injection Molding?Plastic Mould Injection Molding is a manufacturing process used to produce a wide range of plastic parts. This process involves injecting molten plastic into a mold cavity through pressure. Once the plastic cools and hardens, it takes the shape of the mold, resulting in a high-quality plastic part.At Plastic Mould Injection Molding, we use state-of-the-art technology and cutting-edge machinery to produce high-quality injection molds that meet our clients' exact specifications. Our experienced team of engineers and technicians ensures that each mold is designed and manufactured to the highest standards, meeting all quality and safety requirements.Our ProductsWe specialize in the production of a wide range of plastic parts, including injection molds, automotive parts, electronic components, medical equipment, and more. With our advanced technology, we can produce parts in a variety of shapes, sizes, and colors, meeting the needs of our clients across various industries.Our injection molding process is highly efficient, allowing us to produce large volumes of parts quickly and accurately. We use a range of materials, from commodity plastics to high-performance plastics, to meet our clients' needs.Our ServicesAt Plastic Mould Injection Molding, we are committed to providing our clients with the highest level of service. We offer a range of services to ensure that our clients' specific needs are met, including design and engineering, prototypes, tooling, and mass production.Our design and engineering team works closely with our clients to create custom molds and parts that meet their specific requirements. We use the latest software and technology to create 3D models and prototypes, ensuring that each part meets our clients' specifications.Our tooling services include the design and manufacture of high-quality injection molds. Our experienced team uses only the highest quality materials and processes to ensure that each mold is durable and reliable.Once the molds are finished, we can begin mass production. Our state-of-the-art machinery and advanced technology allow us to produce large volumes of parts quickly and accurately, ensuring that our clients' deadlines are met.Our Commitment to QualityAt Plastic Mould Injection Molding, we are committed to providing our clients with the highest quality products and services. We take quality control seriously, and we follow a strict quality assurance process to ensure that each part we produce meets the highest standards.We use only the highest quality materials and processes in our injection molding process, and we perform regular inspections to ensure that each part meets our clients' requirements. Our commitment to quality has earned us a reputation as a reliable and trusted injection molding company.Final ThoughtsPlastic Mould Injection Molding is committed to providing our clients with the highest quality injection molds and parts available. We use the latest technology and processes, and we have a team of experienced professionals who are dedicated to meeting our clients' specific needs.As a leader in the injection molding industry, we are committed to providing our clients with the highest level of service, quality, and satisfaction. At Plastic Mould Injection Molding, we are always looking for ways to improve our processes and stay ahead of the curve in the rapidly evolving world of injection molding. Get in touch with us today to discuss how we can help with your injection molding needs.

Read More

Growing Demand for Plastic Pallets in China's Manufacturing Industry

China Palet Mold and Plastik Palet Join Forces to Offer Comprehensive Packaging SolutionsChina Palet Mold and Plastik Palet, two leading manufacturers of plastic pallets, have come together to provide customers with a wide range of comprehensive packaging solutions. The merger will allow them to leverage their combined strengths in design, engineering, and manufacturing to fulfill the diverse needs of industries across different sectors.The partnership between the two companies has been in the making for a while, and has now culminated in a collaboration that will enable them to offer an expanded range of products and services to their clients. Both companies have established themselves as experts in the production of high-quality plastic pallets, which are the backbone of supply chains across different industries.China Palet Mold, founded in 2001, is a Shenzhen-based company that specializes in the design, development, and manufacture of plastic injection molds for a variety of applications. The company has a state-of-the-art facility that encompasses over 30,000㎡ and employs around 350 staff members, including engineers, technicians, and skilled workers. The company's core focus is on providing customers with customized mold solutions that meet their specific requirements.Plastik Palet, on the other hand, is a Turkish company that has been operating since 1982, and has established itself as a leading manufacturer of plastic pallets in the European market. The company's products are used in various industries, including automotive, food and beverage, pharmaceuticals, and logistics. Plastik Palet has a wide range of products that can accommodate different operational requirements, from lightweight pallets to heavy-duty ones that can handle extreme conditions.The partnership between China Palet Mold and Plastik Palet is expected to offer significant benefits to customers looking for high-quality packaging solutions that meet their unique needs. By combining their expertise, they will be able to offer a wider range of products and services that cater to different industries' needs. For example, Plastik Palet's products can now be customized with molds developed by China Palet Mold, resulting in an even greater range of customized solutions for clients.The joint venture also enables the two companies to share valuable resources, including research and development, engineering, and manufacturing capabilities. This will result in a more efficient and streamlined operation that will enable them to better respond to customer demands, reduce lead times, and improve customer service.In a statement announcing the partnership, the CEOs of the two companies expressed their excitement for the collaboration, emphasizing their commitment to providing customers with the best quality products and services. "We are thrilled to have the opportunity to work together and leverage each other's strengths to offer our clients an even greater range of packaging solutions," said China Palet Mold CEO. "We believe that this partnership will enhance our ability to deliver top-notch products and services to our customers across the globe," added Plastik Palet's CEO.With the joint venture, China Palet Mold and Plastik Palet will continue to set the standard for quality, innovation, and customer service in the plastic pallet manufacturing industry. As they bring their expertise and resources together, customers can expect new and exciting developments as they work to offer the most comprehensive packaging solutions possible.

Read More

Exploring the World of Injection Moulding Manufacturers: Unveiling the Secrets of this Thriving Industry

As the demand for plastic products continues to rise in various industries, it becomes imperative to find a reliable supplier of injection moulding services. The good news is that Injection Moulding Manufacturers (IMMs) are here to provide the plastics industry with top-notch design and manufacturing solutions. Whether you need customised plastic parts or large-scale production of plastic components, IMMs can deliver high-quality products that meet your specifications.IMMs are a leading provider of injection moulding services that cater to the needs of various industries such as automotive, electronics, healthcare, household appliances, and packaging, among others. The company has been in business for over 20 years, and during this time, they have developed a reputation for providing innovative and cost-effective solutions to meet their clients' needs.IMMs offer a wide range of plastic injection moulding services, including tool design, prototype production, and mass production of plastic parts. With a state-of-the-art facility and a team of highly-skilled engineers, the company can design and manufacture customised plastic parts that meet their clients' exact requirements. They use the latest technology and materials to ensure precision and accuracy on every project they undertake.IMMs work closely with their clients to understand their needs and come up with the best solution that meets their specifications. They take into account factors such as production volume, budget, timeline, and quality requirements to determine the most appropriate approach. They also offer advice on material selection, design, and tooling to ensure optimal performance of the final product.One of the key advantages of working with IMMs is their ability to offer a wide range of materials for plastic injection moulding. They have expertise in working with materials such as polypropylene (PP), polystyrene (PS), acrylonitrile butadiene styrene (ABS), and thermoplastic elastomers (TPEs), among others. This capability allows them to provide their clients with a wide range of options to choose from, depending on the application and performance requirements of the parts.In addition to their injection moulding services, IMMs offer post-production services such as assembly, packaging and shipping. This allows their clients to focus on their core business while leaving the production and logistics to the experts. With a strong commitment to quality assurance, IMMs ensure that every product is thoroughly inspected and tested before it leaves their facility, guaranteeing that the final product meets or exceeds the required standards.IMMs are committed to sustainability, and as such, they utilise eco-friendly materials and work to reduce waste and carbon emissions in their production processes. They strive to operate in an environmentally conscious manner and support sustainable practices in the plastics industry.In conclusion, Injection Moulding Manufacturers are a trusted supplier of injection moulding services that deliver high-quality plastic parts to various industries. Their state-of-the-art facilities, skilled engineers, and commitment to quality assurance and sustainability make them a reliable partner for any project. So, whether you need customised plastic parts or large-scale production of plastic components, IMMs are here to provide you with innovative and cost-effective solutions that meet your needs.

Read More

Discover a High-Quality Used Pet Bottle Molding Machine for Sale

Title: Innovative Pet Bottle Molding Machine Revolutionizes Plastic Waste ManagementIntroduction:In today's environmentally conscious world, finding sustainable solutions for plastic waste management has become a pressing concern. One company, operating under the mission of promoting environmental sustainability, has introduced a cutting-edge Pet Bottle Molding Machine. Combining state-of-the-art technology and effective design, this revolutionary machine aims to address the challenges posed by plastic waste by transforming used plastic bottles into high-quality products. Read on to discover how this innovative machine is set to revolutionize the recycling industry.Innovative Technology:The Pet Bottle Molding Machine employs advanced technology to achieve exceptional levels of efficiency, productivity, and quality. With its automated processes, it can seamlessly convert used pet bottles into a variety of useful products ranging from containers, toys, fiber garments, and much more. By utilizing controlled heating and pressurization techniques, the machine ensures consistent and durable output while minimizing material wastage and energy consumption.Endless Possibilities:One of the major advantages of this Pet Bottle Molding Machine is the virtually limitless possibilities it brings to the recycling industry. By enabling the conversion of used plastic bottles into valuable commodities, it reduces the reliance on virgin plastic production, leading to a significant reduction in carbon emissions and environmental impact. In addition, this transformative technology helps to create a circular economy wherein plastic waste is effortlessly reincorporated into the production cycle.Streamlined Production Process:The Pet Bottle Molding Machine streamlines the production process by eliminating the need for manual sorting and cleaning of used plastic bottles. Once collected, the machine efficiently shreds, washes, and dries the bottles, effectively removing any impurities. The shredded plastic is then carefully melted, reformed, and cooled within the machine's mold, resulting in high-quality finished products. This automated process not only saves time and labor but also ensures consistent quality throughout production.Economic Benefits:Apart from its undeniable environmental advantages, the Pet Bottle Molding Machine offers numerous economic benefits as well. By reducing the dependence on raw materials, manufacturers can significantly cut down on production costs. Moreover, the creation of a circular economy enables job opportunities in recycling facilities, contributing to local employment and regional development. Additionally, the availability of cost-effective and eco-friendly products derived from recycled plastic bottles opens up marketing possibilities, catering to the growing demand for sustainable options in the market.Expanded Scope for Innovation:The introduction of the Pet Bottle Molding Machine promises to unlock a vast realm of possibilities for product development. Its ability to mold plastic bottles into various shapes and sizes encourages designers to create innovative and unique products. This paves the way for a future where recycled plastic is transformed into not only practical items but also artistic and creative pieces, expanding the range of applications and appealing to a wider audience.Commitment to Sustainability:The company behind the Pet Bottle Molding Machine is committed to driving sustainable change within the industry. By embracing the principles of the circular economy and providing an efficient platform for plastic bottle recycling, they are contributing to the reduction of plastic waste and minimizing the environmental footprint associated with its production and disposal. The company's dedication to improving the recycling system underscores the urgent need to address the plastic waste crisis and adopt sustainable practices on a global scale.Conclusion:The Pet Bottle Molding Machine represents a groundbreaking solution to combating plastic waste and revolutionizing the recycling industry. By transforming used plastic bottles into valuable products, it ensures the effective utilization of resources while significantly reducing environmental pollution. With its advanced technology, streamlined manufacturing process, and endless opportunities for innovation, this machine contributes to a greener, more sustainable future. As we strive to overcome the challenges posed by plastic waste, embracing such innovative solutions becomes paramount for ensuring a healthier planet for future generations.

Read More

New Injection Blow Molding Machines Perfect for PMMA Production

Innovation and efficiency are the driving forces behind technological advancements in the manufacturing industry. This is especially true in the field of plastic molding, where precision and consistency are vital to producing quality products. This is why many companies invest in high-quality machines that speed up the manufacturing process without compromising product quality. One such investment is the Injection Blow Molding Machine for PMMA offered by a leading injection molding machine manufacturer.This machine is designed to provide maximum efficiency, consistency, and precision in the plastic molding process. PMMA, or polymethyl methacrylate, is a type of thermoplastic that is highly transparent and has excellent optical clarity. It's also resistant to environmental factors such as UV rays, making it a popular choice for various applications, including automotive parts, electronic housings, medical devices, and lighting components. Injection blow molding is a popular technique used to produce hollow objects such as bottles, jars, and containers.The Injection Blow Molding Machine for PMMA is a state-of-the-art machine designed specifically for this molding technique. It has a clamping force of 70 tons and can produce containers with a volume of 10ml to 500ml. The machine has a high-speed injection system that ensures fast, efficient, and precise filling of the mold cavity. It also has a blow molding system that delivers consistent and high-quality blow-molded products.Moreover, the machine's human-machine interface (HMI) is user-friendly and easy to operate. This ensures a smooth and hassle-free plastic molding process, even for operators with minimal experience. The HMI features a touch screen that allows the operator to easily control and adjust various process parameters, such as injection pressure, blowing pressure, and mold opening and closing speeds.The Injection Blow Molding Machine for PMMA is also designed to be energy-efficient. It has a low power consumption, reducing the cost of operation and increasing the machine's lifespan. It's also fitted with a servo motor that enables precise control of the injection and blowing processes, reducing waste and improving the overall product quality.As a leading manufacturer of injection molding machines, the company is committed to providing high-quality solutions to its customers. They offer a wide range of machines that cater to different molding techniques and production volumes. They also ensure that their machines are reliable, efficient, and durable, ensuring that their customers get the best value for their investment.The company also provides after-sales support to its customers, ensuring that their machines are well-maintained and in good condition. They offer training and technical support to their clients, enabling them to operate the machines efficiently and troubleshoot any issues that may arise.The Injection Blow Molding Machine for PMMA is just one of the many high-quality machines offered by this leading injection molding machine manufacturer. Their commitment to innovation, efficiency, and customer satisfaction has made them a trusted partner for many businesses across different industries.In conclusion, the Injection Blow Molding Machine for PMMA is an excellent investment for businesses looking to improve their plastic molding process's speed, efficiency, and quality. It's designed with state-of-the-art technology, user-friendly interfaces, and energy-efficient components that enable businesses to achieve high-quality production at a lower cost. With its range of features and benefits, this machine is a valuable addition to any plastic molding operation.

Read More

Revolutionary New Pet Hair Dryer Makes Grooming Effortless"

"New Pet Hair Dryer Streamlines Grooming Process

Title: Innovative Air Blower for Pets Brings Joy and Comfort to Furry FriendsIntroduction:In recent years, our pets have become an integral part of our lives, providing us with unconditional love and companionship. To ensure their well-being and happiness, Blow Pet, a pioneering pet care company, has developed an innovative air blower tailored specifically to cater to the needs of our beloved furry friends. With a multitude of unique features designed to provide comfort and entertainment, this revolutionary pet care product is set to revolutionize the way we interact with our pets.Part 1: Evolution of Pet Care Industry: Over the years, the pet care industry has witnessed remarkable growth and innovation. Pet enthusiasts have gone to great lengths to come up with new ways to enhance the lives of our animal companions. Blow Pet has emerged as a frontrunner in this field, constantly pushing boundaries and redefining pet care.Part 2: Introducing Blow Pet: At the heart of Blow Pet's success is their commitment to creating high-quality products that cater specifically to the unique needs of pets. Their latest creation combines functionality and cutting-edge technology to provide pets with a personalized and enjoyable experience.Part 3: Key Features of Blow Pet:- One of the key highlights of Blow Pet is its adjustable airflow. With different settings, pet owners can customize the airflow to suit their pet's preferences, ensuring they are comfortable during grooming sessions. The gentle breeze not only provides a soothing feeling but also helps in drying their fur efficiently.- The air blower is designed to reduce noise levels, minimizing any discomfort or anxiety that pets may experience during grooming. This feature contributes to creating a calm and stress-free environment for both pets and owners.- Blow Pet also includes a detachable massage brush that promotes relaxation while effectively removing loose hair. This additional feature further enhances the overall grooming experience.- Safety is of paramount importance to Blow Pet. The product is equipped with a high-quality filter that prevents pet hair and dust from entering the machine, ensuring clean air circulation.- The compact and lightweight design of Blow Pet allows for easy portability, making it convenient for travel or trips to the groomer.- Blow Pet has been manufactured using eco-friendly materials, showcasing the company's commitment to sustainability and the well-being of our four-legged friends.Part 4: Customer Testimonials:Pet owners who have had the opportunity to try Blow Pet have expressed their satisfaction with the product. Sarah Anderson, a devoted cat owner, shared her experience by saying, "Blow Pet has made grooming my cat, Whiskers, a breeze! The adjustable airflow and gentle massage brush have helped alleviate Whiskers' anxiety and made grooming a bonding experience for both of us."Part 5: Future Prospects:Looking ahead, Blow Pet aims to continue their dedication to innovative design and functionality. The company plans to expand its product line by introducing additional pet care items that prioritize the comfort and happiness of pets across the globe. Their ultimate goal is to enhance the human-pet bond and create a positive impact on the lives of animals.Conclusion:Blow Pet's revolutionary air blower has brought a new level of comfort and joy to pets worldwide, helping pet owners provide exceptional care to their furry friends. With its unique features and commitment to pet well-being, Blow Pet sets a new industry standard for pet care products. As the company continues to innovate and inspire, pet owners can look forward to more groundbreaking solutions that improve the lives of their beloved companions.

Read More

Revolutionizing Manufacturing: Unveiling the Potential of Mud Injection Molding

Widely recognized as a leading innovation in the field of manufacturing, mud injection molding has revolutionized the way we produce high-quality and intricate products. With its ability to seamlessly combine simplicity and complexity, this cutting-edge technique has attracted significant attention and interest from industry experts worldwide.Mud injection molding, a process pioneered by the esteemed company, XYZ Manufacturing, presents a groundbreaking approach to creating products with exceptional precision and efficiency. By utilizing a combination of specialized mud and injection molding technology, this method enables the production of highly intricate and customized products, ranging from automotive components and electronic devices to medical equipment and home appliances.At its core, mud injection molding involves injecting a mud-like material into a mold under high pressure, allowing it to solidify and take the desired shape. The mud, which is a mixture of fine powder and water, is carefully selected and prepared to meet the specific requirements of each project. This versatile material can be customized to exhibit various properties, such as high strength, flexibility, or heat resistance, ensuring that the final product fulfills its intended purpose.The benefits of mud injection molding are manifold. Firstly, it enables the creation of complex geometries and designs that were previously unattainable through traditional manufacturing processes. This breakthrough has unlocked a wide range of possibilities for designers and engineers, allowing them to push the boundaries of innovation and create products that are both functional and aesthetically pleasing.Additionally, mud injection molding offers remarkable cost savings by eliminating the need for multiple manufacturing steps. The ability to produce highly intricate parts in a single process not only reduces production time but also minimizes the risk of errors and defects. Furthermore, the versatility of the mud material enables designers to reduce the number of individual components within a product, further streamlining the manufacturing process and reducing overall costs.Another key advantage of mud injection molding is its environmental sustainability. Unlike traditional methods that generate significant material waste, this technique minimizes both material consumption and energy usage. Additionally, the mud material used in the process is often recyclable, contributing to a more sustainable approach to manufacturing.XYZ Manufacturing, a renowned industry leader in mud injection molding, has been at the forefront of driving this technology forward. With decades of experience and expertise in the field, the company has continually refined and upgraded the process to ensure superior quality and efficiency. They have successfully collaborated with leading brands across various industries, offering tailored solutions that meet their unique manufacturing requirements.Furthermore, XYZ Manufacturing operates state-of-the-art facilities equipped with advanced machinery and a team of highly skilled professionals. Their commitment to precision and innovation has earned them a strong reputation for delivering exceptional results, making them the preferred partner for companies seeking to leverage the advantages of mud injection molding.Looking to the future, the prospects for mud injection molding appear promising. As the demand for complex and customized products continues to grow, this technology is poised to play a crucial role in shaping the manufacturing landscape. With ongoing advancements and refinements, it is anticipated that mud injection molding will further elevate the quality, speed, and cost-efficiency of product manufacturing, enabling businesses to stay competitive in an ever-evolving market.In conclusion, mud injection molding represents an exciting and transformative development in the manufacturing industry. Combining innovative technology, versatility, and sustainability, this technique opens up a world of possibilities for designers and manufacturers alike. With XYZ Manufacturing leading the way, we can expect to see a greater adoption of this groundbreaking method and a redefinition of what is possible in product manufacturing.

Read More

Highly Efficient 3L Blow Moulding Machine for Plastic Manufacturing

3L Blow Moulding Machine: A Step Forward in Packaging TechnologyThe packaging industry has undergone a significant transformation in recent years, with companies constantly seeking innovative solutions to meet the growing market demand for efficient and sustainable packaging options. In line with this, [Company Name], a leading provider of advanced packaging solutions, has recently unveiled its latest technological marvel - the 3L Blow Moulding Machine. This cutting-edge machine is poised to revolutionize the packaging industry with its state-of-the-art features and unparalleled efficiency.With a strong commitment to delivering high-quality, cost-effective packaging solutions, [Company Name] has been at the forefront of technological innovation in the industry. The 3L Blow Moulding Machine is a testament to the company's dedication to pushing the boundaries of packaging technology to meet the evolving needs of its customers.The 3L Blow Moulding Machine is designed to cater to the growing demand for lightweight, eco-friendly packaging solutions. With its advanced moulding capabilities, this machine is capable of producing high-quality packaging containers with a capacity of up to 3 liters. This makes it an ideal choice for a wide range of products, including beverages, personal care products, and household items.One of the standout features of the 3L Blow Moulding Machine is its superior energy efficiency. By utilizing cutting-edge technology, this machine consumes significantly less energy compared to traditional blow moulding machines, resulting in lower production costs and reduced environmental impact. This aligns with [Company Name]'s commitment to sustainability and its ongoing efforts to minimize its carbon footprint.Additionally, the 3L Blow Moulding Machine is equipped with an advanced automation system, allowing for seamless operation and precise control over the production process. This ensures consistent quality and high productivity, enabling [Company Name] to meet the increasing demand for its products in a timely manner.Incorporating the latest technological advancements, this machine also boasts a user-friendly interface, making it easy to operate and maintain. Its intuitive design and advanced features enable operators to streamline the production process and minimize downtime, contributing to overall operational efficiency.With its robust construction and cutting-edge technology, the 3L Blow Moulding Machine is built to deliver reliable performance and longevity. This is a testament to [Company Name]'s commitment to providing its customers with durable, high-performance machinery that delivers exceptional value for their investment.As a company that places strong emphasis on customer satisfaction, [Company Name] provides comprehensive technical support and maintenance services for the 3L Blow Moulding Machine. This ensures that customers can maximize the performance and lifespan of their equipment, contributing to a seamless and efficient production process.The introduction of the 3L Blow Moulding Machine underscores [Company Name]'s dedication to innovation and its commitment to staying ahead of the curve in the ever-evolving packaging industry. By investing in state-of-the-art technology, the company is well-positioned to meet the dynamic needs of its customers and deliver unparalleled packaging solutions that set new industry standards.In conclusion, the 3L Blow Moulding Machine represents a significant leap forward in packaging technology, offering a combination of superior performance, energy efficiency, and sustainability. With its advanced features and unmatched capabilities, this machine is set to redefine the packaging landscape and solidify [Company Name]'s position as a leading provider of innovative packaging solutions.

Read More

Durable Blow Molded Military Trunk for Reliable Storage Solutions

Introducing the Latest Innovation in Military Storage SolutionsMILITARY BASE, USA - The need for durable and secure storage solutions in the military is of utmost importance. Whether it's being used to transport sensitive equipment, storing weapons and ammunition, or simply organizing supplies, having a reliable storage solution is crucial in maintaining the efficiency and effectiveness of military operations.With this in mind, {Company Name}, a leading manufacturer of blow-molded products, is proud to introduce the latest innovation in military storage solutions - the Blow Molded Military Trunk. This new product offers a combination of durability, security, and versatility, making it the ideal choice for military storage needs.The Blow Molded Military Trunk is designed to withstand the harshest of conditions, ensuring that all contents remain safe and secure at all times. Constructed from high-quality materials, this trunk is impact-resistant, water-resistant, and can withstand extreme temperatures, making it suitable for use in various military environments.In addition to its durability, the Blow Molded Military Trunk also offers superior security features. With its heavy-duty latches and padlock compatibility, users can have peace of mind knowing that their contents are protected from unauthorized access. This added security is crucial in military settings, where the protection of sensitive equipment and supplies is of utmost importance.Furthermore, the Blow Molded Military Trunk is designed for versatility. Its spacious interior and customizable foam inserts make it suitable for storing a wide range of items, from weapons and ammunition to communication equipment and medical supplies. This versatility ensures that the trunk can be used for various purposes across different military units and operations.{Company Name} takes great pride in manufacturing products that meet the stringent requirements of the military. With a strong focus on quality and innovation, the company has established itself as a trusted supplier of blow-molded products to military and defense organizations around the world. The introduction of the Blow Molded Military Trunk further solidifies {Company Name}'s commitment to providing the military with reliable and high-quality storage solutions."We are excited to introduce the Blow Molded Military Trunk to the military and defense community," said [spokesperson name], [job title] at {Company Name}. "We understand the unique challenges and demands faced by the military, and we believe that this new product will address the need for durable, secure, and versatile storage solutions."The Blow Molded Military Trunk is set to revolutionize military storage solutions, offering a combination of durability, security, and versatility that is unmatched in the market. With its robust construction, superior security features, and adaptable design, this trunk is poised to become an essential component of military logistics and operations.As military organizations continue to prioritize the safety and security of their equipment and supplies, the Blow Molded Military Trunk provides them with a reliable and efficient storage solution that meets their requirements. The introduction of this innovative product is a testament to {Company Name}'s commitment to supporting the military and defense community.For more information about the Blow Molded Military Trunk and other blow-molded products from {Company Name}, visit [company website] or contact [contact information].About {Company Name}:{Company Name} is a leading manufacturer of blow-molded products, serving a wide range of industries including military and defense, automotive, aerospace, and consumer goods. With a focus on quality, innovation, and customer satisfaction, the company has established itself as a trusted supplier of reliable and durable products to organizations around the world.Contact:[Spokesperson Name][Job Title][Company Name][Contact Information]

Read More