Custom Made Blow Molding Plastic Snow Goose Decoy Head Parts

By:Admin

The company, which prefers to remain anonymous, specializes in creating customized blow molding plastic products for a variety of industries. They have a long history of working with ABS, PVC, PP, HDPE, and POM materials and have a deep understanding of the unique properties of each one. This expertise allows them to create high-quality, customized products that meet the specific needs of their clients.

Their latest innovation is the spelly snow goose decoy head parts, which are designed to be lightweight, durable, and weather-resistant. These parts are essential for creating lifelike decoys that can be used in hunting and wildlife photography. By using blow molding techniques, the company is able to create intricate, detailed parts that are nearly impossible to distinguish from real goose heads.

What sets this company apart is their commitment to customization. They understand that every client has unique needs and requirements, and they work closely with each one to create products that meet those needs. Whether it's a specific size, shape, color, or texture, this company has the expertise and equipment to bring their clients' visions to life.

In addition to their expertise in blow molding plastic, this company also prides itself on its commitment to quality. They adhere to strict quality control standards throughout the production process to ensure that every product that leaves their facility is of the highest quality. This dedication to quality has earned them a reputation for reliability and consistency in the industry.

One of the key advantages of working with this company is their ability to handle large orders with ease. Their state-of-the-art facilities and skilled workforce allow them to produce high volumes of products without compromising on quality or turnaround time. This makes them an ideal partner for companies that require large quantities of customized blow molding plastic products.

Of course, it's not just their expertise and capabilities that set this company apart - it's also their commitment to customer service. They understand that the needs of their clients are always changing, and they are always willing to go the extra mile to ensure that those needs are met. From the initial consultation to the final delivery, their clients can expect open communication, attention to detail, and a dedication to exceeding expectations.

As this company continues to make a name for itself in the industry, it's clear that they are a force to be reckoned with. Their expertise, commitment to quality, and dedication to customization make them a valuable partner for any company in need of blow molding plastic products. Whether it's spelly snow goose decoy head parts or any other customized product, this company has the skills and resources to deliver exceptional results.

Company News & Blog

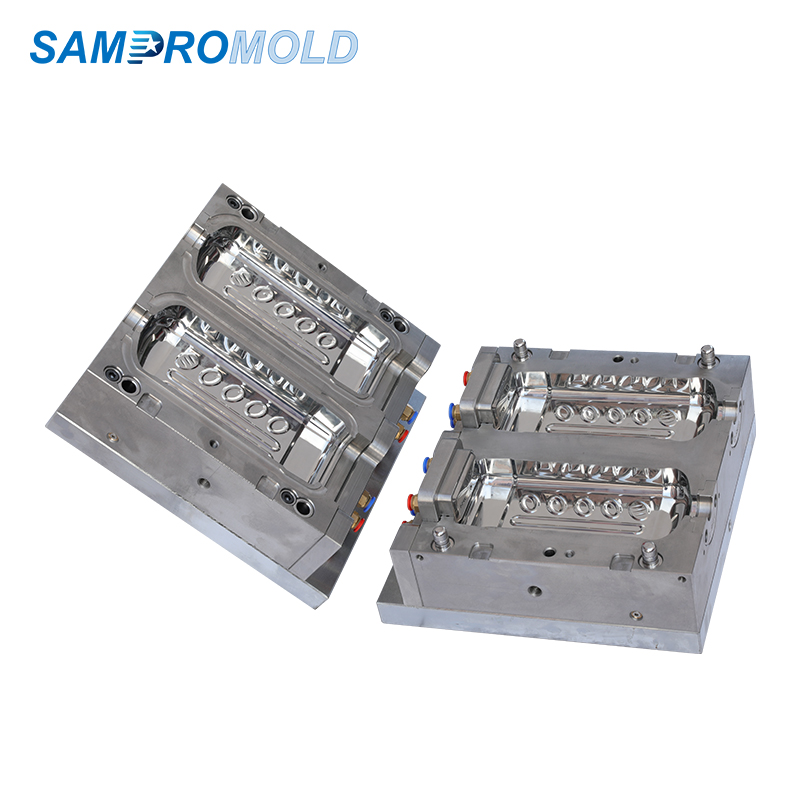

High-Quality Plastic Mold Set for PET Products Offered in Latest News

Title: Industry-leading Pet Plastic Mold Set Revolutionizes Production ProcessesIntroduction (80 words):[Company Name], a renowned pioneer in the manufacturing industry, continues to push the boundaries of innovation with the development of their groundbreaking Pet Plastic Mold Set. This state-of-the-art mold set aims to redefine production processes and streamline operations in the plastics industry. By eliminating wastage, minimizing costs, and improving overall efficiency, [Company Name] solidifies its position as a frontrunner in delivering sustainable and cutting-edge solutions to its global clientele.Content:As the plastics industry continues to rapidly expand, companies are constantly seeking novel ways to optimize production processes, reduce costs, and enhance sustainability practices. Addressing these growing demands, [Company Name] is proud to unveil its highly acclaimed Pet Plastic Mold Set, which promises to revolutionize the manufacturing landscape.1. Unparalleled Precision and Versatility (150 words):The Pet Plastic Mold Set by [Company Name] is designed to deliver unparalleled precision and versatility in the production of various plastic products. With its advanced technology and innovative features, this mold set offers manufacturers the ability to mold PET (Polyethylene Terephthalate) materials into a wide range of shapes and sizes. This paves the way for the creation of high-quality bottles, containers, and packaging materials, among other items, meeting the diverse needs of industries such as food and beverage, pharmaceuticals, and cosmetics.One of the key highlights of the Pet Plastic Mold Set is its exceptional precision, ensuring consistency and accuracy in every mold produced. By eliminating variations, defects, and imperfections commonly associated with traditional molding techniques, manufacturers can experience reduced production downtime and improved product reliability.Additionally, this mold set boasts exceptional versatility, allowing for seamless customization. Manufacturers can easily modify molds to cater to specific product designs and requirements, thereby offering a tailored approach to the manufacturing process.2. Unmatched Efficiency and Sustainability (150 words):[Company Name]'s Pet Plastic Mold Set has been developed with a strong focus on optimizing operational efficiency and global sustainability efforts. By incorporating advanced technologies and manufacturing techniques, the mold set results in significant resource and energy savings during the production process.The streamlined design of this mold set ensures quick mold changes, reducing downtime and increasing overall manufacturing efficiency. Furthermore, its innovative cooling system maximizes cycle times, allowing for faster production rates and increased output.Moreover, the Pet Plastic Mold Set by [Company Name] promotes sustainability by reducing waste and minimizing the environmental footprint. The mold set is designed to minimize material usage, resulting in reduced scrap generation and overall cost savings. By utilizing recycled PET materials, manufacturers can contribute to a circular economy and reduce dependence on virgin plastic production.3. Enhanced Durability and Longevity (150 words):Durability is an essential aspect of any mold set, and [Company Name]'s Pet Plastic Mold Set stands out by providing exceptional quality and longevity. Made from high-grade materials, these molds are engineered to withstand prolonged use, high temperatures, and demanding production conditions.Robust and corrosion-resistant, the Pet Plastic Mold Set guarantees extended lifespan and consistent performance. This ensures that manufacturers experience minimal downtime and increased overall productivity, translating into higher returns on their investment.Moreover, these molds undergo rigorous quality control and testing procedures before reaching the market. This intensive process ensures that each mold meets the highest standards of quality, safety, and reliability, thereby instilling confidence in manufacturers who rely on [Company Name] for their production needs.Conclusion (80 words):[Company Name]'s Pet Plastic Mold Set sets a new benchmark in the plastics industry, offering manufacturers unmatched precision, versatility, efficiency, and sustainability. With its innovative features and superior quality, this mold set is poised to transform production processes, streamline operations, and drive overall industry growth. As [Company Name] continues to pioneer groundbreaking solutions, it reinforces its commitment to shaping a sustainable and prosperous future for the plastics manufacturing sector.

Extrusion Blow Molding Machine for Milk and Yogurt Bottles

Milk Yogurt Bottle Extrusion Blow Molding Machine Revolutionizes Packaging IndustryInnovation and advancements in technology have always been the driving forces behind progress in every industry. With the ever-increasing demand for efficient and sustainable packaging solutions, companies are continually striving to develop cutting-edge machinery that can meet these requirements. Among these revolutionary advancements is the Milk Yogurt Bottle Extrusion Blow Molding Machine.[Company Name], a leader in the manufacturing and design of packaging machinery, has introduced this groundbreaking machine that is set to revolutionize the packaging industry. With the perfect blend of state-of-the-art technology and innovative design, this blow molding machine promises to bring a new era of efficiency, cost-effectiveness, and environmental friendliness to the production of milk and yogurt bottles.The Milk Yogurt Bottle Extrusion Blow Molding Machine is designed to produce high-quality bottles for the dairy industry quickly. Its advanced extrusion blow molding process ensures precise molding of bottles with consistent wall thickness, resulting in sturdier and more durable packaging. This feature is paramount to maintaining the integrity of products such as milk and yogurt, which are susceptible to spoilage if not properly stored.Environmental consciousness has become a crucial consideration for both consumers and manufacturers. The Milk Yogurt Bottle Extrusion Blow Molding Machine addresses this concern by utilizing sustainable materials and reducing waste. By utilizing advanced machinery that optimized the use of raw materials, manufacturers can minimize the carbon footprint generated during the production process. Additionally, the machine's high-speed output ensures a higher production rate, thus reducing energy consumption.Furthermore, this revolutionary machine is equipped with automated controls and intelligent systems that enhance productivity and operational convenience. The smart control system allows for seamless integration with other production processes, streamlining the manufacturing line and reducing downtime. The user-friendly interface and intuitive software enable easy configuration, adjustments, and troubleshooting, making it an ideal choice for both seasoned operators and newcomers to the industry.One of the key advantages of the Milk Yogurt Bottle Extrusion Blow Molding Machine is its flexibility in terms of bottle design and size. Manufacturers can easily adapt the machine to produce bottles of various shapes and volumes, allowing them to cater to evolving consumer preferences and market demands. This versatility enables companies to introduce new milk and yogurt products quickly, giving them a competitive edge in an ever-changing industry.The introduction of the Milk Yogurt Bottle Extrusion Blow Molding Machine reiterates [Company Name]'s commitment to continuous innovation and customer satisfaction. With a proven track record of delivering high-quality machinery and exceptional customer service, the company has established itself as a leader in the packaging industry. By investing in cutting-edge technology and embracing sustainability, [Company Name] is setting new benchmarks for the industry to follow.In conclusion, the Milk Yogurt Bottle Extrusion Blow Molding Machine represents a significant leap forward in packaging technology. With its ability to produce durable and sustainable bottles efficiently, this machine will undoubtedly transform the way milk and yogurt are packaged. [Company Name]'s commitment to innovation and customer satisfaction ensures that they remain at the forefront of the industry, providing solutions that meet the evolving needs of manufacturers and consumers alike.

High-Quality Moulds for Bottle Caps: A Complete Guide

Moulds For Bottle Caps: A Key Component of {Company's} Manufacturing Line{Company} is a leading manufacturer of various plastic products, including bottle caps, containers, and packaging materials. The company has built a solid reputation for delivering high-quality plastic products to their clients around the world. One of the key components of their manufacturing line is the moulds for bottle caps, which play a crucial role in producing top-notch bottle caps that meet the industry's standards.Moulds for bottle caps are essential tools in the production of plastic bottle caps. They are used to shape and form the plastic material into the desired cap design. These moulds are custom-made to fit the specific requirements of the bottle cap design, ensuring that each cap is produced with precision and consistency.{Company} has invested heavily in the latest technology and equipment for their mould manufacturing process. This includes state-of-the-art CNC machines, advanced software for designing and testing the moulds, and a team of highly skilled engineers and technicians who oversee the entire production process. With these resources, the company is able to produce moulds that are not only high in quality but also highly efficient in their performance.In addition to their cutting-edge technology, {Company} also places a strong emphasis on quality control and testing. Each mould undergoes rigorous testing to ensure that it meets the company's strict standards for performance and durability. This commitment to quality has earned {Company} a solid reputation in the industry, with many companies trusting them to provide reliable and durable moulds for their bottle cap production needs.The moulds for bottle caps produced by {Company} are used in a wide range of industries, including the beverage, pharmaceutical, and cosmetic industries. This demonstrates the versatility and adaptability of their moulds, which can be customized to meet the unique demands of each industry. Whether it's a standard bottle cap design or a more complex and intricate one, {Company} has the expertise and capabilities to deliver the right mould for the job.Furthermore, {Company} places a strong emphasis on sustainable and environmentally-friendly manufacturing practices. Their mould manufacturing process is designed to minimize waste and reduce energy consumption, supporting their commitment to sustainability. This aligns with the growing trend towards eco-friendly packaging solutions, as more companies prioritize sustainable practices in their production processes.As a testament to their expertise and reliability, {Company} has developed strong partnerships with leading brands in the beverage and pharmaceutical industries. These partnerships are a testament to the quality and performance of their moulds for bottle caps, as well as the company's dedication to meeting the unique needs of their clients.Looking ahead, {Company} is committed to continuous innovation and improvement in their mould manufacturing process. They are constantly exploring new materials, technologies, and techniques to further enhance the quality and efficiency of their moulds. This ongoing dedication to excellence positions {Company} as a trusted partner for companies looking for top-notch moulds for their bottle cap production needs.In conclusion, {Company} is a leading manufacturer of moulds for bottle caps, offering high-quality and reliable solutions for the beverage, pharmaceutical, and cosmetic industries. With their state-of-the-art technology, commitment to quality, and focus on sustainability, {Company} is well-positioned to continue meeting the evolving demands of their clients and the industry as a whole.

High-Quality Injection Molds for Lures: A Comprehensive Guide

Lure Injection Molds: The Backbone of High-Quality Fishing LuresIn the world of fishing, the right equipment can make all the difference between a successful day on the water and coming home empty-handed. One piece of gear that is essential for creating high-quality fishing lures is the lure injection mold. These molds are the key to producing lures that are consistent in shape, size, and color, which is crucial for attracting and catching fish.{Company}, a leading manufacturer of fishing tackle equipment, has been at the forefront of producing top-quality lure injection molds for more than a decade. The company's commitment to innovation and precision engineering has made its molds a staple in the industry, trusted by professional and recreational anglers alike.The lure injection molds produced by {Company} are designed to meet the specific needs of anglers who demand nothing but the best. Made from high-quality materials and engineered with precision, these molds are capable of producing lures with intricate details and lifelike shapes. This attention to detail is what sets {Company}'s molds apart from the competition, giving anglers the confidence that their lures will perform as expected.One of the key features of {Company}'s lure injection molds is their versatility. Whether an angler is looking to create a simple jig or a complex swimbait, {Company} has a mold to suit their needs. The company offers a wide range of mold designs, including single- and multi-cavity molds, to accommodate different lure sizes and styles. This flexibility allows anglers to customize their lures to match the specific fishing conditions they will encounter.In addition to their versatility, {Company}'s lure injection molds are known for their durability. Constructed from durable materials, these molds are built to withstand the rigors of regular use, ensuring that they will continue to produce high-quality lures for years to come. This durability gives anglers peace of mind, knowing that their investment in {Company}'s molds will pay off in the long run.{Company} also takes great pride in its commitment to customer satisfaction. The company's team of experts is dedicated to providing anglers with the support and guidance they need to get the most out of their lure injection molds. From product recommendations to troubleshooting advice, {Company} is there for its customers every step of the way, ensuring that they have a positive experience with their products.As part of its dedication to innovation, {Company} continues to develop new mold designs and technology to meet the evolving needs of anglers. The company invests heavily in research and development, constantly pushing the boundaries of what is possible with lure injection molds. This ongoing commitment to improvement ensures that {Company} remains a leader in the industry, setting the standard for high-quality fishing tackle equipment.For anglers who demand the best from their fishing gear, {Company}'s lure injection molds are an essential tool for creating professional-grade lures. With their precision engineering, durability, and versatility, these molds are the backbone of high-quality fishing lures, helping anglers to achieve success on the water time and time again. Whether an angler is a seasoned pro or just starting out, {Company}'s molds are a game-changer in the pursuit of the perfect catch.In conclusion, {Company} continues to lead the way in the fishing tackle industry, providing anglers with the tools they need to succeed. With its commitment to innovation, quality, and customer satisfaction, {Company} has solidified its reputation as a trusted source for high-quality fishing tackle equipment, including its industry-leading lure injection molds. For anglers who demand nothing but the best from their gear, {Company} is the brand of choice.

Top Manufacturers of Blow Molds and Bottle Molds in China: A Comprehensive Guide" => "A Comprehensive Guide to Blow Molds and Bottle Molds Manufacturers in China

China Blow Mold and Bottle Mold, a leading manufacturer in the mold industry, is constantly pushing the boundaries of innovation and technology. With a strong focus on research and development, the company is known for its high-quality products and exceptional customer service.Headquartered in Guangzhou, China, China Blow Mold and Bottle Mold has been in operation for over three decades. Over the years, the company has built a reputation for excellence and reliability in providing blow molds and bottle molds to a wide range of industries, including packaging, beverages, cosmetics, pharmaceuticals, and more.One of the key factors that sets China Blow Mold and Bottle Mold apart from its competitors is its unwavering commitment to technological advancement. The company has a state-of-the-art manufacturing facility equipped with the latest machinery and equipment. Its team of skilled engineers and technicians work tirelessly to develop innovative mold designs that cater to the specific needs of the customers.In recent years, China Blow Mold and Bottle Mold has made significant strides in adopting advanced technologies like computer-aided design (CAD) and computer-aided manufacturing (CAM). These technologies have revolutionized the mold manufacturing process, allowing for more precise and efficient production. This has helped the company in reducing lead times and ensuring faster delivery of products to its customers.Apart from its commitment to cutting-edge technology, China Blow Mold and Bottle Mold places great emphasis on quality control. The company has implemented a strict quality management system that adheres to international standards. This ensures that each mold produced meets the highest levels of precision and durability. All molds undergo rigorous testing and inspections before they are shipped to customers.Furthermore, China Blow Mold and Bottle Mold strives to provide excellent customer service. The company believes in building long-term relationships with its clients by understanding their specific requirements and delivering personalized solutions. Its dedicated sales team is always ready to assist customers with any queries or concerns, ensuring a smooth and hassle-free experience.In addition to its domestic presence, China Blow Mold and Bottle Mold has also expanded its reach internationally. It has successfully exported its molds to numerous countries around the world, including the United States, Europe, Southeast Asia, and more. This global presence has helped the company in gaining valuable insights into different markets and understanding the diverse needs of its customers.Looking ahead, China Blow Mold and Bottle Mold aims to continue its growth trajectory by further investing in research and development. The company plans to explore new technologies and materials to enhance the quality and efficiency of its molds. It also aims to expand its product range and offer a wider variety of molds to cater to the evolving needs of its customers.In conclusion, China Blow Mold and Bottle Mold has established itself as a reputable and reliable manufacturer in the mold industry. By staying at the forefront of technological advancements and prioritizing customer satisfaction, the company continues to be a trusted partner for businesses across various sectors. With its commitment to excellence, China Blow Mold and Bottle Mold is poised to achieve even greater success in the coming years.

Discover the Advantages of Tri-Cavity Blow Molding for PET Products

Molde 3 Cavidades Soplado PET Introduces a Revolutionary Solution for PackagingMolde 3 Cavidades Soplado PET, one of the leading manufacturers of PET packaging in the world, recently introduced a new line of products that promises to revolutionize the packaging industry. The company has developed a new technology that allows for the production of PET bottles with three cavities instead of the traditional one or two cavities. This innovation not only promises to cut down production time and increase efficiency, but also offers several other benefits for both manufacturers and consumers alike.The new technology developed by Molde 3 Cavidades Soplado PET has been designed to address some of the major challenges faced by the packaging industry. One of the key problems faced by manufacturers is the need for quick and efficient production of high-quality packaging. With the new three-cavity technology, the manufacturing process is significantly streamlined, reducing production time by up to 30%. This means that manufacturers can produce more bottles in less time, leading to increased efficiency and profitability.In addition to faster production times, Molde 3 Cavidades Soplado PET's new technology also offers several other benefits. The three cavities in the PET bottles provide greater strength and durability, making them less prone to breaking or cracking during transport. This is a major advantage for both manufacturers and consumers, as it reduces the risk of wastage and decreases the need for re-packaging.Furthermore, PET bottles produced with the new three-cavity technology also offer greater flexibility and customization options. Manufacturers can create bottles with different shapes and sizes, ranging from small travel-sized bottles to larger containers for bulk purchases. This allows companies to cater to a wider range of customer needs, ultimately driving growth and profitability.Molde 3 Cavidades Soplado PET's new three-cavity technology is also more environmentally sustainable than traditional PET bottles. By reducing the need for re-packaging and improving durability, the use of the new technology can lead to a significant decrease in plastic waste. Additionally, the company uses recyclable materials in the production of its PET bottles, further promoting sustainability and eco-friendliness.The introduction of the new three-cavity technology by Molde 3 Cavidades Soplado PET has been met with great enthusiasm from the packaging industry. Several manufacturers have already expressed interest in the technology and are planning to incorporate it into their production processes. The new technology is expected to drive growth and innovation in the industry, offering a competitive advantage for companies that adopt it.Molde 3 Cavidades Soplado PET is a highly reputable company dedicated to the production of high-quality PET bottles. Their commitment to innovation and sustainability has made them a leader in the industry, with their products being used by some of the largest companies in the world. With the introduction of their new three-cavity technology, Molde 3 Cavidades Soplado PET is poised to continue its growth and leadership in the industry, bringing cutting-edge solutions to manufacturers and consumers alike.In conclusion, Molde 3 Cavidades Soplado PET's new three-cavity technology is a game-changer for the packaging industry. It offers several advantages, including faster production times, greater durability, and greater flexibility and customizability. Furthermore, the technology is environmentally sustainable, promoting the reuse of materials and reducing plastic waste. With its commitment to innovation and sustainability, Molde 3 Cavidades Soplado PET is poised to continue its leadership in the industry and drive growth and profitability for manufacturers and consumers alike.

High-Quality 100ml Blow Molding Machine for HDPE Material

The company's introduction:With over 20 years of experience in the manufacturing industry, our company has been at the forefront of innovation and excellence. We specialize in the production of high-quality plastic molding machines and have a strong reputation for delivering reliable and efficient solutions to our customers. Our commitment to excellence and customer satisfaction has made us a trusted name in the industry.Our 100ml HDPE blow molding machine is the latest addition to our product lineup, and it is set to revolutionize the production of plastic containers. This new machine is designed to offer unparalleled efficiency and precision, making it the ideal choice for businesses looking to optimize their production processes.The HDPE blow molding machine is capable of producing 100ml plastic containers at a rapid pace, making it perfect for high-volume production. Its advanced technology enables it to deliver consistent and high-quality results, ensuring that every container meets the strictest standards of quality and durability.One of the key features of the machine is its user-friendly interface, which allows operators to easily control and monitor the production process. This intuitive system streamlines operations, reducing the need for manual intervention and minimizing the risk of errors. Additionally, the machine is equipped with state-of-the-art safety features, ensuring a secure working environment for operators.The 100ml HDPE blow molding machine is also designed with sustainability in mind. It is energy-efficient, consuming minimal power while delivering maximum output. Its innovative design minimizes material waste, making it an environmentally friendly choice for businesses looking to reduce their carbon footprint.Furthermore, the machine can be adapted to accommodate different molds, allowing for versatility in production. This flexibility means that businesses can easily switch between different container sizes and shapes, meeting the varying demands of their customers without the need for multiple machines.In addition to its cutting-edge technology, our company provides comprehensive support and maintenance services for the 100ml HDPE blow molding machine. Our team of skilled technicians is on hand to offer assistance and guidance, ensuring that our customers can optimize the performance of their machines and maximize their return on investment.The introduction of the 100ml HDPE blow molding machine represents our ongoing commitment to driving innovation and delivering value to our customers. We are confident that this new addition to our product range will empower businesses to enhance their production capabilities and achieve new levels of efficiency and quality.With its advanced features, user-friendly interface, sustainability benefits, and comprehensive support services, the 100ml HDPE blow molding machine is set to become a game-changer in the plastic molding industry. We are excited to bring this innovative solution to businesses seeking to elevate their production processes and unlock new opportunities for growth and success.

New Injection Mold Technology for Pet Preform Production

Yizumi Injection Mold Unveils State-of-the-Art Solution for PET Preform ManufacturingIn recent years, the demand for PET preforms has soared, and the market for these essential components shows no sign of slowing down. To cater to this increasing demand, Yizumi Injection Mold has unveiled its revolutionary injection mold solution, designed to revolutionize the PET preform manufacturing industry.With a history of excellence spanning several years, Yizumi Injection Mold has established itself as a leader in the injection molding industry. The company's commitment to continuously innovate and improve its technologies has resulted in the introduction of this game-changing mold solution.The newly unveiled mold by Yizumi Injection Mold is engineered to meet the ever-growing demands of the PET preform market, offering superior efficiency, precision, and reliability. By leveraging cutting-edge manufacturing techniques and state-of-the-art materials, the mold ensures optimal performance and consistency, streamlining the PET preform manufacturing process.Key to the mold's success is the integration of advanced technologies that enhance its functionality and durability. Yizumi Injection Mold's engineers have employed meticulous precision engineering and rigorous testing to deliver exceptional results. The mold boasts superior cooling efficiency, ensuring faster production cycles and minimized downtime.Furthermore, the mold has been designed with a focus on longevity and durability. It is built to withstand the rugged demands of high-volume production, providing manufacturers with a reliable and long-lasting solution that maximizes their return on investment.In addition to its impressive technical specifications, the Yizumi Injection Mold for PET preforms offers unmatched versatility. The mold is compatible with a wide range of PET resins, allowing manufacturers to adapt to varying market requirements swiftly. This flexibility not only provides cost-saving benefits but also opens up new avenues for product innovation and diversification.The company's commitment to sustainability shines through in the Yizumi Injection Mold design. The mold incorporates eco-friendly features that reduce energy consumption and minimize waste generation. By optimizing the cooling process and incorporating efficient material distribution channels, the mold ensures minimal environmental impact without compromising on performance.Yizumi Injection Mold's commitment to customer satisfaction is evident in its comprehensive after-sales service. The company offers extensive technical support, assisting manufacturers in optimizing their production processes, troubleshooting issues, and ensuring continuous productivity. Additionally, the prompt availability of spare parts and professional maintenance services ensures minimal downtime, maximizing manufacturing efficiency.With the launch of this groundbreaking mold, Yizumi Injection Mold solidifies its position as an industry innovator. By combining cutting-edge technology, reliability, and exceptional versatility, the company offers a comprehensive solution for PET preform manufacturers worldwide.As the demand for PET preforms continues to rise, Yizumi Injection Mold remains at the forefront of the industry, constantly striving to improve and exceed customer expectations. With their innovative mold solution, they provide manufacturers with the tools they need to stay competitive in a dynamic market.In summary, Yizumi Injection Mold's newly unveiled solution for PET preform manufacturing sets a new standard in the industry. With its advanced technology, reliability, and environmental consciousness, the mold offers manufacturers unrivaled efficiency, flexibility, and sustainability. Yizumi Injection Mold's commitment to customer satisfaction, backed by comprehensive after-sales services, further strengthens the company's position as a global leader in the injection molding industry.

Double Head Blow Moulding: Everything You Need to Know

Blow Moulding Double Head technology has revolutionized the packaging industry with its innovative and efficient production processes. This cutting-edge technology, offered by leading companies like {}, has significantly improved the manufacturing of plastic containers and packaging, leading to high-quality products that meet the demands of modern consumers.With the growing need for sustainable and innovative packaging solutions, companies are turning to blow moulding double head technology to meet these demands. This technology offers a cost-effective and efficient way to produce plastic containers and packaging for a variety of industries, including food and beverage, pharmaceuticals, and personal care products.By incorporating blow moulding double head technology, companies are able to create lightweight and durable packaging that is not only visually appealing but also environmentally friendly. This technology allows for the production of containers that are resistant to damage, moisture, and environmental stress, making them ideal for protecting products during storage and transportation.The unique design of blow moulding double head technology allows for the production of intricate and customized packaging designs, providing companies with the flexibility to meet the specific requirements of their products. This versatility has made this technology a popular choice for companies looking to differentiate their products in a competitive market.Leading the way in blow moulding double head technology is {}, a renowned company with a long-standing reputation for excellence in the packaging industry. With a strong commitment to innovation and customer satisfaction, {} has been at the forefront of developing and implementing this cutting-edge technology to meet the evolving needs of their clients.{}’s state-of-the-art blow moulding double head equipment and machinery, combined with their team of skilled professionals, have set new standards for quality, efficiency, and reliability in the production of plastic containers and packaging. Their dedication to delivering top-notch solutions has earned them a loyal customer base and a stellar reputation in the industry.The company’s extensive experience and expertise in blow moulding double head technology have enabled them to cater to a wide range of industries, providing customized and sustainable packaging solutions that exceed the expectations of their clients. By continually investing in research and development, {} remains at the forefront of technological advancements, ensuring that their customers have access to the most advanced and efficient packaging solutions available.In addition to their commitment to innovation, {} places a strong emphasis on sustainability and environmental responsibility in their production processes. With blow moulding double head technology, the company can minimize waste and energy consumption, while also utilizing recyclable materials in their packaging production. This approach not only benefits the environment but also helps their clients meet their own sustainability goals.As the demand for sustainable and efficient packaging solutions continues to grow, the adoption of blow moulding double head technology is expected to rise. Leading companies like {} are well-positioned to meet this growing demand, thanks to their dedication to innovation, quality, and customer satisfaction.In conclusion, blow moulding double head technology has become a game-changer in the packaging industry, offering companies the ability to produce high-quality, sustainable, and customizable packaging solutions. With companies like {} at the helm of this technological revolution, the future of packaging looks promising, with a focus on innovation, efficiency, and environmental responsibility.

Revolutionary Screw Cap Mould: The Future of Packaging

Title: Innovative Screw Cap Mould Technology Revolutionizes Bottle PackagingIntroduction:In the fast-paced and constantly evolving world of packaging, the demand for advanced and efficient solutions is ever-increasing. One such technology that is revolutionizing bottle packaging is the Screw Cap Mould, developed by an industry-leading company. This groundbreaking innovation offers significant advantages over traditional packaging methods, ensuring improved sealing, preservation, and overall consumer experience.Company Introduction:With a firm commitment to quality and innovation, the company behind the Screw Cap Mould has been a prominent player in the industry for several decades. They specialize in designing and manufacturing cutting-edge packaging solutions for a wide range of industries, including food and beverages, pharmaceuticals, and cosmetics. Known for their expertise and state-of-the-art facilities, they have established themselves as a trusted partner for businesses seeking efficient and reliable packaging solutions.1. Enhanced Sealing and Security:The Screw Cap Mould boasts an advanced design that ensures enhanced sealing capabilities, mitigating the risk of leakage and contamination. Utilizing precision engineering and high-quality materials, the mould guarantees a tight seal, preventing any unwanted exposure to air, moisture, or other external factors that could compromise the product's quality. Consequently, consumers can trust the integrity of the contents, ensuring a positive user experience.2. Versatility and Customization:One of the key advantages of the Screw Cap Mould technology is its versatility and compatibility with various bottle types and sizes. Irrespective of the container material, be it glass or plastic, the mould can be customized to fit seamlessly, offering a perfect fit and ensuring excellent functionality. Additionally, businesses can personalize the screw caps further, incorporating logos, branding, and other design elements, thus creating a distinct and marketable packaging solution.3. Sustainability and Environmental Benefits:In today's eco-conscious era, sustainably-minded packaging is in high demand. The Screw Cap Mould addresses this need by incorporating environmentally friendly features. It is designed to be reusable, reducing the need for single-use packaging and minimizing waste. Furthermore, the use of recyclable materials ensures that the mould aligns with the principles of circular economy, helping businesses meet their sustainable packaging goals while reducing their carbon footprint.4. Improved Consumer Experience:The Screw Cap Mould not only enhances the packaging's functionality but also contributes to an improved consumer experience. The ease of opening and resealing the screw cap ensures convenience and minimizes spillage risks. The design allows for efficient pouring, preventing drips and leaks during usage. Moreover, the enhanced sealing capabilities maintain the product's freshness and shelf life, providing consumers with a reliable and enjoyable experience every time.5. Cost-Effective Solution:Implementing the Screw Cap Mould technology offers cost-effective benefits for businesses in the long run. With increased sealing and preservation capabilities, the risk of product spoilage and damage is significantly reduced, reducing potential economic losses. The customization options allow for increased brand visibility and recognition, ultimately improving market positioning and revenue generation.Conclusion:As the world embraces innovation and technology, the Screw Cap Mould is emerging as a game-changer in bottle packaging. With its advanced sealing capabilities, versatility, and customization options, the mould provides businesses with a comprehensive solution that enhances their products' integrity and market appeal. Additionally, its sustainable features and improved consumer experience established it as an ideal choice in today's packaging landscape. With the introduction of this pioneering technology, businesses across various industries can look forward to elevating their packaging game to new heights.