High-quality Blow Molding Machines for Detergent Bottles

By:Admin

In today's fast-paced world, the demand for consumer goods is constantly on the rise. Companies are continuously striving to meet the increasing demand for products such as detergent bottles by enhancing their production processes. One company at the forefront of this innovation is The Company, a leading manufacturer of blow molding machines.

The Company, established in 1998, has been committed to providing high-quality and innovative blow molding machines for various industries. With a focus on research and development, they have consistently delivered cutting-edge solutions to their customers. Their latest achievement, the Detergent Bottle Blow Molding Machine, is set to revolutionize the production of detergent bottles.

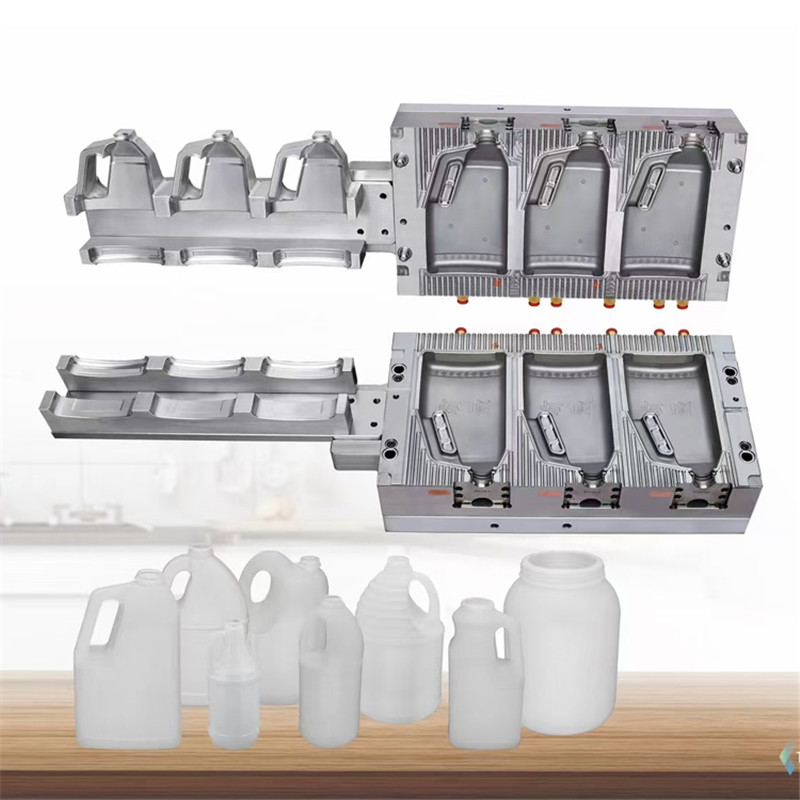

The Detergent Bottle Blow Molding Machine is designed to meet the specific needs of companies in the detergent manufacturing industry. It is capable of producing a wide range of bottle sizes, from small travel-sized containers to larger bulk packaging. This flexibility allows detergent manufacturers to cater to the diverse needs of their customers while streamlining their production processes.

One of the key features of the Detergent Bottle Blow Molding Machine is its high efficiency. With advanced technology and precise engineering, the machine is able to deliver a high output while maintaining consistent quality. This not only increases the overall production capacity but also ensures that each detergent bottle meets the required standards.

Moreover, the Detergent Bottle Blow Molding Machine is designed for ease of operation. The user-friendly interface and intuitive controls make it simple for operators to set up and monitor the production process. This reduces the training time for new staff and minimizes the risk of errors during operation.

In addition to its efficient and user-friendly design, the Detergent Bottle Blow Molding Machine is also equipped with state-of-the-art safety features. The Company has always prioritized the safety of its machines and ensures that all necessary precautions are in place to protect the operators and maintain a safe working environment.

The Company has also taken environmental considerations into account during the development of this machine. The Detergent Bottle Blow Molding Machine incorporates energy-saving technologies and sustainable practices to minimize its carbon footprint. This aligns with the growing emphasis on corporate social responsibility and sustainable manufacturing processes.

The introduction of the Detergent Bottle Blow Molding Machine by The Company marks a significant milestone in the manufacturing industry. It addresses the specific needs of detergent manufacturers while setting new standards for efficiency, reliability, and sustainability in blow molding technology.

The response from the industry has been overwhelmingly positive, with many companies expressing interest in adopting this technology. The Company has already received orders from leading detergent manufacturers, and the machine is expected to make a significant impact on the production of detergent bottles worldwide.

In conclusion, the Detergent Bottle Blow Molding Machine by The Company represents a major advancement in the field of blow molding technology. Its innovative design, high efficiency, user-friendly operation, and focus on safety and sustainability make it a game-changer for the detergent manufacturing industry. As the demand for consumer goods continues to grow, solutions like the Detergent Bottle Blow Molding Machine will play a crucial role in enabling companies to meet the needs of the market efficiently and responsibly.

Company News & Blog

Top Injection Molding Companies in the Industry

One of the largest injection molding companies, {} has recently made a significant impact in the industry. With its state-of-the-art facilities and cutting-edge technology, the company has positioned itself as a leader in injection molding and plastic manufacturing.{} is known for its commitment to innovation and its ability to provide high-quality products to a wide range of industries. The company's expertise in injection molding allows it to produce a diverse array of products, ranging from consumer goods to automotive components.One of the key factors that sets {} apart from its competitors is its dedication to customer satisfaction. The company works closely with its clients to understand their unique needs and develop bespoke solutions that meet and exceed their expectations. With a focus on quality and reliability, {} has earned a reputation as a trusted partner for businesses seeking injection molding services.In addition to its dedication to customer satisfaction, {} is also committed to sustainability and responsible manufacturing practices. The company is continuously exploring new ways to minimize its environmental impact and reduce waste. By implementing environmentally friendly processes and materials, {} is contributing to a more sustainable future for the injection molding industry.With a strong focus on research and development, {} is constantly pushing the boundaries of what is possible in injection molding. The company invests heavily in new technologies and equipment to stay at the forefront of the industry. This commitment to innovation ensures that {} can offer its clients the most advanced and efficient solutions for their injection molding needs.Furthermore, {} places a strong emphasis on quality control throughout the manufacturing process. The company has stringent measures in place to ensure that every product that leaves its facilities meets the highest standards of quality and reliability. By maintaining such high levels of quality, {} has built a solid reputation for excellence in the injection molding industry.One of the most impressive aspects of {} is its diverse capabilities. The company has the expertise and resources to handle projects of all sizes and complexities, making it a valuable partner for businesses of any scale. Whether a client requires a small batch of customized parts or a large-scale production run, {} has the capabilities to deliver exceptional results.In conclusion, {} has established itself as one of the largest and most prominent injection molding companies in the industry. With its unwavering commitment to innovation, quality, and customer satisfaction, the company continues to set the standard for excellence in injection molding. As the demand for high-quality plastic products continues to grow, {} is well-positioned to meet the needs of a wide range of industries and provide them with the advanced solutions they require.

How to Prevent Mold in Your Home

Cap Mold Company, a leading manufacturer of molds and injection molding machines, has recently announced the launch of their latest product, a state-of-the-art cap mold designed to meet the growing demand for high-quality caps in the packaging industry. The new cap mold is expected to revolutionize the manufacturing process by providing faster production speeds, improved product quality, and cost-saving benefits for companies in the beverage and food packaging sectors.With over 20 years of experience in the industry, Cap Mold Company has established itself as a trusted supplier of precision molds and injection molding machines to companies around the world. The company's commitment to innovation and quality has earned them a strong reputation and a loyal customer base. Their team of experienced engineers and technicians continuously strive to develop cutting-edge solutions that meet the evolving needs of the industry.The newly launched cap mold is the result of extensive research and development efforts aimed at addressing the challenges faced by manufacturers in the packaging industry. The mold features advanced design elements that allow for efficient production processes, ensuring consistent quality and precision in every cap produced. In addition, the mold is compatible with a wide range of materials, giving manufacturers the flexibility to meet diverse product specifications and market demands.One of the key highlights of the new cap mold is its ability to enhance production speeds without compromising on quality. With faster cycle times and reduced downtime, manufacturers can significantly increase their output, thereby meeting the growing demand for caps in a timely manner. This improved efficiency is expected to result in substantial cost savings for companies, making the new cap mold a valuable investment for businesses looking to optimize their manufacturing processes.Furthermore, the mold is designed to deliver superior product quality, with tight tolerances and consistent performance across production runs. This ensures that the caps produced meet the highest standards of strength, durability, and aesthetics, enhancing the overall appeal of the packaged products. As a result, companies can differentiate themselves in the market by offering superior packaging solutions that meet consumer expectations for quality and reliability.The launch of the new cap mold reflects Cap Mold Company's ongoing commitment to driving innovation and value for their customers. By leveraging their expertise and technological capabilities, the company aims to empower manufacturers with the tools they need to stay ahead in a competitive market landscape. The new cap mold is set to become an essential asset for companies looking to streamline their production processes and achieve greater efficiency and profitability.In addition to the new cap mold, Cap Mold Company continues to offer a comprehensive range of molds and injection molding machines to cater to a diverse set of industry requirements. Their product portfolio includes solutions for various packaging applications, including closures, containers, and specialty packaging items. With a focus on customization and reliability, the company ensures that their customers have access to solutions that address their unique needs and help them achieve their production goals.As they move forward, Cap Mold Company remains committed to driving progress in the packaging industry through innovation, quality, and customer-centric solutions. With the launch of the new cap mold, the company is poised to further solidify its position as a leading provider of molds and injection molding technology, empowering manufacturers to achieve greater success in the global market.In conclusion, the unveiling of the new cap mold by Cap Mold Company marks a significant milestone in the company's pursuit of excellence and innovation. The product is poised to make a significant impact on the packaging industry by enabling manufacturers to elevate their production processes, improve product quality, and achieve cost-saving benefits. With a solid track record of delivering cutting-edge solutions, Cap Mold Company is well-positioned to empower companies with the tools they need to thrive in a dynamic and competitive market environment.

Ultimate Guide to Bottle Blowing Molds: Everything You Need to Know

Title: Innovative Bottle Blowing Mold Revolutionizes Manufacturing ProcessIntroduction:In today's rapidly evolving manufacturing industry, companies are constantly striving to increase efficiency and reduce costs while maintaining the highest quality standards. One company addressing these demands is [Company Name], a leading player in the field of mold manufacturing. Recently, [Company Name] has introduced an innovative bottle blowing mold that promises to revolutionize the production process for numerous industries.[Company Name] is renowned for its constant focus on research and development, investing substantial resources into creating cutting-edge solutions for its clients. With a commitment to staying ahead of market trends, the company has successfully maintained its position as a trusted partner to various manufacturers worldwide.The New Bottle Blowing Mold:The latest achievement by [Company Name] is its state-of-the-art bottle blowing mold, which offers unparalleled benefits to the manufacturing sector. This revolutionary mold has garnered significant attention due to its exceptional design, innovative features, and potential to reshape the way bottles are produced across industries.Innovative Design and Features:The newly introduced bottle blowing mold incorporates several groundbreaking design elements that enhance its functionality and performance. One notable feature is its modular design, allowing for easy customization and adaptation to diverse manufacturing requirements. This design feature ensures optimal efficiency while reducing production costs, making it a highly sought-after solution for manufacturers.Furthermore, the bottle blowing mold incorporates cutting-edge technologies, such as precision control mechanisms that enable consistent and precise bottle shaping. This ensures uniformity in bottle dimensions and quality throughout the production process. By minimizing production variation, [Company Name]'s mold helps manufacturers maintain high-quality standards while improving overall productivity.Implications for Industries:The introduction of [Company Name]'s bottle blowing mold has far-reaching implications for various industries reliant on bottle production. The mold's adaptability enables manufacturers to produce bottles for a wide range of applications, including food and beverage, pharmaceuticals, cosmetics, and household products. This versatility offers manufacturers unprecedented flexibility and reduces the need for multiple molds, optimizing inventory management and cost-effectiveness.Additionally, the mold's precise control mechanism ensures that the produced bottles meet stringent regulatory requirements for safety and product integrity. This eliminates the risk of faulty bottles entering the market, enabling manufacturers to maintain consumer trust and avoid costly product recalls.Benefits for Manufacturers:By adopting [Company Name]'s bottle blowing mold, manufacturers stand to benefit in numerous ways. Firstly, the mold's modular design streamlines the production process, reducing downtime for mold changes and minimizing overall production costs. This not only saves manufacturers money but also enables them to react swiftly to market demands, leading to a competitive edge.Moreover, the consistent mold performance and enhanced product quality achieved through precision control mechanisms contribute to waste reduction and improved overall efficiency. With higher production yields and less material wastage, manufacturers can generate higher profits while minimizing their environmental footprint.Conclusion:[Company Name]'s introduction of the groundbreaking bottle blowing mold signifies a significant step forward in the manufacturing industry. The innovative design, modular flexibility, and precise control mechanisms of this mold offer manufacturers unparalleled efficiency, cost-effectiveness, and product quality. As a result, various industries can benefit from this cutting-edge solution, producing standardized, high-quality bottles to meet consumer demands effectively. [Company Name] continues to exemplify its commitment to providing state-of-the-art solutions, solidifying its position as a leader in mold manufacturing for a global clientele.

Essential Components for Injection Molding: A Guide

Injection Mold Components (IMC) is a leading supplier of high-quality mold components for the plastic injection molding industry. With over 30 years of experience, IMC has built a strong reputation for providing innovative solutions and exceptional customer service.The company offers a wide range of products including ejector pins, sleeves, blades, and mold bases, all of which are designed to meet the exacting standards of precision and durability required in the injection molding process. IMC's components are used in a variety of industries including automotive, medical, consumer goods, and aerospace.One of the key factors that sets IMC apart from its competitors is their commitment to quality. The company has strict quality control measures in place to ensure that every product that leaves their facility meets the highest standards. This dedication to quality has earned IMC the trust and loyalty of their customers, many of whom have been with the company for decades.In addition to their superior products, IMC also offers a range of value-added services including custom design and engineering, technical support, and rapid delivery. Their team of experienced engineers and customer service representatives work closely with clients to develop tailored solutions that meet their specific needs and exceed their expectations.IMC's dedication to customer satisfaction has earned them a strong reputation in the industry, and the company has built lasting relationships with some of the largest and most respected companies in the injection molding sector. Their commitment to excellence has also led to numerous awards and accolades, further cementing their position as a leader in the mold component industry.To ensure that they remain at the forefront of the industry, IMC invests heavily in research and development, constantly seeking new and innovative ways to improve their products and services. The company is always exploring new materials, technologies, and manufacturing processes to stay ahead of the curve and provide their customers with the best possible solutions.In recent years, IMC has also expanded its global reach, establishing partnerships and distribution networks in key markets around the world. This has allowed the company to serve an even wider customer base and to support the growing demand for their high-quality products.Looking to the future, IMC remains committed to providing the best mold components and services in the industry. The company is constantly seeking new opportunities for growth and expansion, while never losing sight of the values that have made them successful – innovation, quality, and customer satisfaction.As the injection molding industry continues to evolve, IMC will be there every step of the way, offering the products and support that their customers need to succeed. With their unparalleled expertise, unwavering commitment to quality, and dedication to innovation, IMC is well positioned to remain a leader in the mold component industry for many years to come.

Blow Molding Techniques for Producing Pet Bottles

Blow Molding For Pet BottlesBlow molding is a manufacturing process used to create hollow plastic parts, including pet bottles. This process involves the use of a blow molding machine, which heats up plastic resin and then shapes it into a hollow form through the use of air pressure. Blow molding is a cost-effective and efficient way to produce large volumes of pet bottles for various industries, including the food and beverage, pharmaceutical, and personal care sectors.The company, {} is a leading manufacturer of blow molded pet bottles. With over 20 years of experience in the industry, they have established themselves as a trusted supplier of high-quality pet bottles for a wide range of applications. {} has a state-of-the-art manufacturing facility equipped with the latest blow molding machines, allowing them to produce pet bottles in different shapes, sizes, and colors to meet the specific needs of their customers.The company is committed to using the best materials and production techniques to ensure that their pet bottles are of the highest quality. They work closely with their clients to develop custom bottle designs and provide a range of services, including labeling and packaging, to meet their unique requirements. {} places a strong emphasis on sustainability and is continuously working to reduce their environmental impact by using eco-friendly materials and optimizing their manufacturing processes.In recent news, {} has announced the addition of new blow molding machines to their production line, enhancing their capacity to meet the growing demand for pet bottles. These new machines are equipped with advanced technology to improve efficiency and precision in the manufacturing process. This investment demonstrates {}'s commitment to staying at the forefront of the industry and providing their customers with the best possible products and services.The company's dedication to innovation and customer satisfaction has earned them a strong reputation in the market. Their pet bottles are known for their durability, clarity, and suitability for various packaging needs. {}'s extensive experience and expertise in blow molding enable them to offer competitive pricing and fast turnaround times, making them a preferred choice for businesses looking for reliable pet bottle suppliers.With a focus on quality, reliability, and sustainability, {} continues to be a key player in the blow molding industry. They are constantly exploring new opportunities to expand their product range and improve their manufacturing capabilities to better serve their customers. Their commitment to excellence and their strong track record make {} a trusted partner for businesses looking for top-notch pet bottles for their packaging needs.In conclusion, blow molding is an essential process for producing pet bottles, and {} is a leading manufacturer in this field. Their dedication to quality, innovation, and customer satisfaction sets them apart from their competitors and makes them a preferred choice for businesses in need of high-quality pet bottles. With a focus on sustainability and continuous improvement, {} is well-positioned to meet the evolving demands of the market and remain a key player in the blow molding industry.

Discover the Latest Advancements in Flip Top Cap Mould Technology

[Company Name], a leading manufacturer in the plastic molding industry, has recently unveiled its latest innovation, the Flip Top Cap Mould. Designed to serve the growing demand for convenience and practicality in packaging, this cutting-edge mold is set to revolutionize the industry.The Flip Top Cap Mould is meticulously crafted using advanced techniques and superior quality materials, ensuring durability and long-lasting performance. With its sleek design and user-friendly features, this mold enables efficient production of flip top caps that meet the highest industry standards.One of the key features of the Flip Top Cap Mould is its versatility. This mold is capable of producing caps in various sizes, allowing manufacturers to cater to a wide range of products, from personal care items to food and beverages. Its adaptability makes it an ideal choice for companies looking to streamline their production process and reduce costs.In addition to its versatility, the Flip Top Cap Mould boasts exceptional efficiency. Its innovative design allows for faster production cycles, enabling manufacturers to meet tight deadlines and increase overall productivity. This increased efficiency not only saves time but also reduces labor costs, making it an economical choice for businesses of all sizes.Moreover, the Flip Top Cap Mould incorporates advanced technology to ensure consistent quality. Precision engineering guarantees that each cap produced is identical in shape and size, offering a seamless fit with the accompanying containers. This feature is crucial for companies looking to maintain brand integrity and ensure customer satisfaction.Furthermore, the Flip Top Cap Mould is designed with user convenience in mind. Its ergonomic design reduces the effort required for assembly, making it easy for consumers to open and close the caps. This simple yet effective feature enhances the overall user experience, making it a popular choice among customers.The introduction of the Flip Top Cap Mould aligns with [Company Name]'s commitment to innovation and customer satisfaction. With years of industry experience and a dedicated team of experts, the company has continuously pushed the boundaries of what is possible in the plastic molding sector. By constantly striving for excellence, they have earned a reputation as a reliable and forward-thinking manufacturer.[Company Name] takes pride in its state-of-the-art manufacturing facilities and meticulous quality control processes. From concept to production, each step is carefully monitored to ensure that the final product exceeds expectations. The Flip Top Cap Mould is a testament to their dedication to delivering outstanding results.As consumers increasingly prioritize convenience and functionality, the Flip Top Cap Mould presents an exciting opportunity for companies to meet evolving customer demands. Its adaptability, efficiency, and user-friendly features position it as a game-changer in the packaging industry.With the introduction of the Flip Top Cap Mould, [Company Name] reinforces its position as a leading manufacturer and supplier of high-quality plastic molds. This innovative product not only benefits businesses by streamlining their operations but also enriches the consumer experience. As the industry embraces this groundbreaking technology, it is clear that [Company Name] is at the forefront of shaping the future of plastic molding.

Plastic Bottle Extrusion Blow Molding Machine: An Overview of the Latest Technology

Title: Advancements in Plastic Bottle Extrusion Blow Molding Technology Revolutionize Manufacturing EfficiencyIntroduction:The plastic manufacturing industry has witnessed a significant breakthrough with the introduction of the next-generation Plastic Bottle Extrusion Blow Molding Machine. This cutting-edge technology, free from the constraints of traditional methods, promises to revolutionize the production of plastic bottles, offering enhanced efficiency, cost-effectiveness, and sustainability.Company Introduction:Our company, a renowned leader in the plastic manufacturing industry, has been at the forefront of designing and developing advanced machinery for over a decade. With a strong commitment to innovation, we constantly strive to meet the evolving needs of our customers and contribute to a sustainable future. Our dedicated team of engineers and technicians works tirelessly to push the boundaries of plastic extrusion blow molding technology.Revolutionizing the Bottle Manufacturing Process:Traditional blow molding processes often result in excessive material wastage and limited design flexibility. However, our state-of-the-art Plastic Bottle Extrusion Blow Molding Machine introduces a groundbreaking three-layer co-extrusion technology that eliminates these limitations. By employing this innovative approach, manufacturers can achieve uniform thickness distribution, enhance product strength, and significantly reduce material consumption.Enhanced Efficiency and Productivity:The new Plastic Bottle Extrusion Blow Molding Machine streamlines the production process, enabling a vast range of bottle sizes to be manufactured with high speed and precision. Equipped with an advanced robotic arm system, the machine reduces the need for manual handling, increasing productivity and ensuring consistent output. Furthermore, the automated system minimizes the risk of human error, resulting in fewer defects and improved product quality.Cost-Effectiveness and Optimized Resource Utilization:The three-layer co-extrusion technology integrated into the machine optimizes resource utilization, resulting in substantial cost savings for manufacturers. By reducing material wastage and enhancing the structural strength of the bottles, companies can fulfill their production requirements with significantly less raw material. This not only contributes to cost-effectiveness but also fosters environmental sustainability by reducing plastic waste.Customizable Bottle Design Options:The Plastic Bottle Extrusion Blow Molding Machine allows for unmatched design flexibility, enabling manufacturers to create unique bottle shapes that meet the demands of diverse industries. By utilizing various molds and employing precise control over the co-extrusion process, our machine empowers manufacturers to produce bottles that are not only visually appealing but also functionally optimized.Focus on Sustainability:In line with the growing environmental concerns surrounding plastic waste, our Plastic Bottle Extrusion Blow Molding Machine aligns with our commitment to sustainability. By reducing material consumption and optimizing resource utilization, the technology significantly reduces the environmental impact of plastic bottle production. This not only benefits manufacturers but also contributes to the global effort of creating a greener and more sustainable future.Conclusion:The introduction of the Plastic Bottle Extrusion Blow Molding Machine heralds a new era in plastic bottle manufacturing, revolutionizing the industry with its enhanced efficiency, cost-effectiveness, and sustainable production capabilities. Equipped with cutting-edge three-layer co-extrusion technology, this advanced machinery paves the way for improved productivity, reduced material wastage, and customizable design options. As our company continues to push the boundaries of innovation, we remain committed to offering solutions that not only meet the current needs but also contribute to a more sustainable future.

Blow Molding Machines: An In-Depth Look at Pricing and Factors to Consider

Blow Molding Machine Price: Driving Innovation and Affordability in the Manufacturing IndustryThe blow molding industry has experienced significant growth in recent years, fueled by increasing demand for plastic packaging and a rise in consumer preferences for affordable and lightweight materials. As a result, companies are constantly seeking innovative solutions to improve production efficiency and lower costs.One prominent player in this field, a global leader in blow molding machinery, has recently unveiled a new line of blow molding machines that promise to revolutionize the manufacturing industry. With a focus on affordability without compromising quality, the company aims to equip manufacturing businesses with highly efficient tools that meet their production needs at a competitive price point.Blow molding machines are essentially used to create hollow plastic parts and containers in a wide range of industries, including food and beverage, cosmetics, pharmaceuticals, and automotive. These machines employ a process of melting plastic resins and stretching them into a desired shape, resulting in strong and lightweight products.The newly introduced blow molding machines by this industry-leading company incorporate advanced technology and numerous features designed to enhance productivity and reduce downtime. These machines offer improved automation, precision controls, and faster cycle times, ensuring more efficient production rates. By streamlining the manufacturing process, businesses can achieve higher output and lower costs, ultimately resulting in a competitive edge.One of the standout features of this new line of blow molding machines is their versatility. With the ability to produce a wide variety of shapes and sizes, these machines cater to the diverse needs of manufacturers. Whether it's producing bottles, containers, or other bespoke plastic products, the flexibility of these machines allows businesses to adapt to changing market demands without significant retooling or investment.In addition to their technological advancements, these blow molding machines also prioritize sustainability. With growing global concern over environmental issues, such as plastic waste and carbon emissions, manufacturers are under increasing pressure to adopt sustainable practices. The new machines offer energy-efficient solutions, reducing electricity consumption and minimizing their carbon footprint. This not only benefits the environment but also helps manufacturers align with evolving regulations and consumer preferences.Furthermore, the affordability of these blow molding machines presents a significant advantage for small and medium-sized enterprises (SMEs). Historically, the high cost of machinery has posed a barrier for smaller businesses wanting to enter the blow molding industry. However, with the availability of more affordable options without compromising on quality, SMEs can now compete on a level playing field, opening up new opportunities and driving economic growth.The company's commitment to customer satisfaction extends beyond product affordability. Recognizing the importance of aftersales support, the company offers comprehensive technical assistance, training programs, and readily available spare parts. This ensures that manufacturers can maximize the longevity and performance of their blow molding machines, ultimately reducing maintenance costs and minimizing downtime.As the demand for plastic products continues to rise, driven by global population growth and changing consumer habits, the blow molding industry is poised for further expansion. The introduction of affordable and innovative blow molding machines by this industry leader reflects its commitment to driving this growth by empowering manufacturers with efficient tools at a competitive price point.In conclusion, with a focus on affordability, innovation, and sustainability, the recent unveiling of a new line of blow molding machines by a global industry leader has the potential to transform the manufacturing industry. By offering efficient and versatile solutions, these machines enable businesses to increase production rates, reduce costs, and meet market demands without compromising on quality. As a result, small and medium-sized manufacturers can unlock new opportunities, contributing to economic growth and competitiveness in the blow molding industry.

Advanced Blow Machine Technology: A Look at the Latest Innovations in the Industry

The Blow Machine industry is witnessing substantial growth over the years, as the demand for efficient and high-quality blow molding machines continues to rise in various sectors such as packaging, automotive, and consumer goods. One company at the forefront of this industry is {}, a leading manufacturer of blow molding machines and related equipment.Established in the early 2000s, {} has proven itself to be a reliable and innovative player in the blow machine industry. The company specializes in the design, manufacturing, and distribution of a wide range of blow molding machines, including extrusion blow molding machines, injection blow molding machines, and stretch blow molding machines. With a strong focus on research and development, {} has been able to consistently introduce advanced technologies and solutions to meet the evolving needs of its customers.Recently, {} has introduced a new line of blow molding machines that are equipped with state-of-the-art features, setting a new standard for efficiency, productivity, and quality in the industry. The company's latest machines are designed to offer faster cycle times, lower energy consumption, and improved reliability, providing significant cost savings and performance benefits for its customers.In addition to its cutting-edge machines, {} also offers a comprehensive range of services to support its customers, including technical support, maintenance, and training programs. This customer-centric approach has helped {} to build long-term partnerships with clients across the globe, earning a reputation for excellence and reliability in the blow machine industry.As the demand for blow molding machines continues to grow, {} has been expanding its presence in key markets around the world. The company has established a strong global network of sales and service partners, allowing it to effectively reach and support customers in different regions. This strategic approach has enabled {} to serve a diverse range of industries, from food and beverage packaging to automotive components and industrial products.Moreover, {} is committed to sustainability and environmental responsibility, offering eco-friendly solutions that help its customers minimize their carbon footprint and reduce waste. The company's energy-efficient machines and recyclable materials contribute to a greener manufacturing process, aligning with the global trend towards more sustainable production practices.Looking ahead, {} is poised to continue its growth and innovation in the blow machine industry, leveraging its expertise and resources to address new challenges and opportunities in the market. From advanced technologies to exceptional service, {} is dedicated to providing its customers with the best solutions for their blow molding needs, driving success and efficiency in their production operations.With its strong track record and forward-thinking approach, {} remains a trusted and respected name in the blow machine industry, poised for further growth and success in the years to come. As the market evolves and demands continue to change, {} is well-positioned to lead the way in delivering cutting-edge solutions and exceptional value to its customers around the world.

High-Quality Injection Molds: A Look at the Latest News and Trends

Accurate Injection Molds Inc, a leading manufacturer of injection molds, has made significant strides in the industry with its innovative solutions and commitment to excellence. The company has been at the forefront of injection molding technology for over two decades, providing high-quality, precision-engineered molds for a wide range of industries. With a focus on delivering exceptional performance and reliability, Accurate Injection Molds has established itself as a trusted partner for companies seeking to streamline their manufacturing processes and achieve superior results.Founded in 1998, Accurate Injection Molds has quickly earned a reputation for excellence in the design and production of precision molds for plastic injection molding. The company’s state-of-the-art facilities and highly skilled team of engineers and technicians enable it to offer a comprehensive range of services, including product design, mold making, and production molding. Accurate Injection Molds is committed to meeting the unique needs of each client, providing tailored solutions that meet the highest standards of quality and performance.Accurate Injection Molds has continually invested in the latest technology and equipment, ensuring that it remains at the cutting edge of the industry. The company’s advanced manufacturing capabilities allow it to produce molds with unparalleled precision and consistency, delivering superior results for its clients. Whether it’s a complex, multi-cavity mold or a simple prototype, Accurate Injection Molds has the expertise and resources to deliver exceptional products that meet the most demanding specifications.One of the key factors that sets Accurate Injection Molds apart from its competitors is its commitment to continuous improvement and innovation. The company’s team of engineers and designers are constantly exploring new ideas and techniques to enhance its mold-making processes and deliver even greater value to its clients. This dedication to innovation has enabled Accurate Injection Molds to stay ahead of the curve and adapt to the ever-changing needs of the industry.Accurate Injection Molds serves a diverse range of industries, including automotive, aerospace, medical, consumer goods, and electronics. The company’s ability to meet the unique requirements of each industry segment has made it a trusted partner for some of the world’s leading companies. Accurate Injection Molds takes pride in its ability to deliver exceptional results while maintaining a cost-effective approach, making it a preferred choice for companies seeking to optimize their manufacturing processes.In addition to its technical expertise, Accurate Injection Molds is also known for its exceptional customer service and support. The company works closely with its clients throughout the entire process, from initial concept to final delivery, ensuring that their needs and expectations are met at every stage. Accurate Injection Molds understands the importance of clear communication and collaboration, and strives to build lasting, productive relationships with its clients.As Accurate Injection Molds continues to expand its capabilities and reach, it remains committed to its core values of integrity, innovation, and customer satisfaction. The company’s dedication to quality and excellence has positioned it as a leader in the injection molding industry, and it is poised for even greater success in the years to come.Accurate Injection Molds is a company that stands out in the injection molding industry, excelling in design and production. Accurate Injection Molds, a leading manufacturer of precision molds, has a proven track record of providing superior products and services to a diverse range of industries. With a focus on innovation, reliability, and customer satisfaction, Accurate Injection Molds has earned a well-deserved reputation as a trusted partner for companies seeking high-quality molds.